Part installing system

A technology of parts installation and parts, applied in the field of parts installation system, can solve problems such as low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

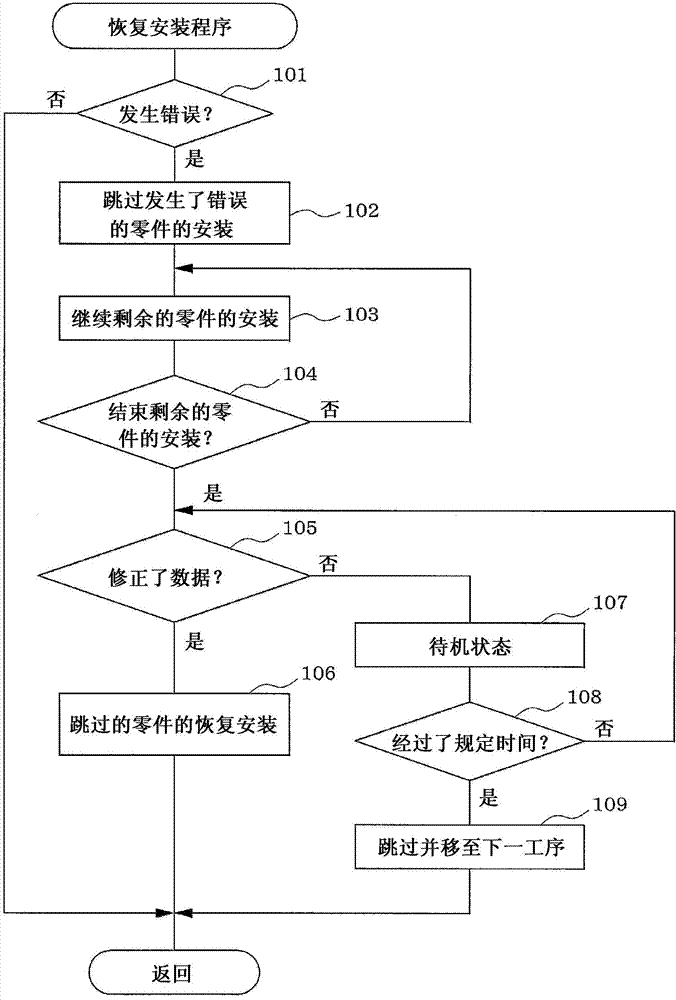

[0025] Hereinafter, an example embodying a mode for implementing the present invention will be described.

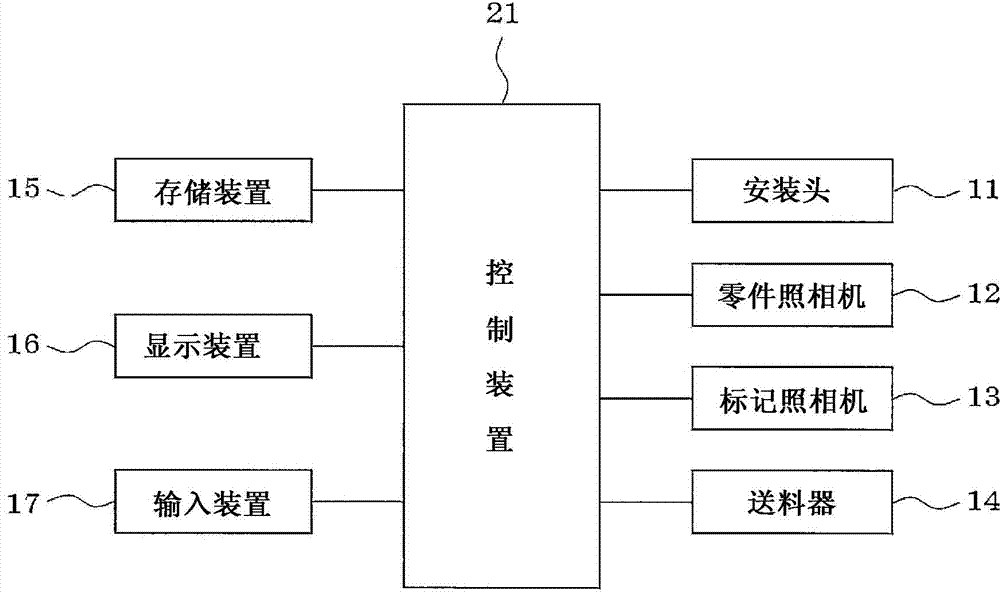

[0026] Such as figure 1 As shown, the parts mounting machine is provided with: a mounting head 11 holding one or more suction nozzles (not shown); a parts camera 12 that photographs parts sucked to the suction nozzles; and a reference position mark on the surface of the circuit board The marking camera 13; the feeder 14 for supplying parts; storing the later described image 3 A storage device 15 (storage unit) for various data such as various programs such as recovery installation programs, image processing data, etc.; a display device 16 such as a liquid crystal display, a CRT, etc.; an input device 17 such as a keyboard and a mouse.

[0027] The control device 21 of the parts mounting machine sucks the parts supplied from the feeder 14 through the suction nozzle of the mounting head 11, photographs the parts with the parts camera 12, and compares the part image with the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com