A combined type grounding terminal

A grounding terminal and combined technology, which is applied in the direction of connecting contact materials and bendable lead wires, etc., can solve the problems of too many grounding points, easy to pull out wrongly, poor contact, etc., to save human resources, prevent accidents, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

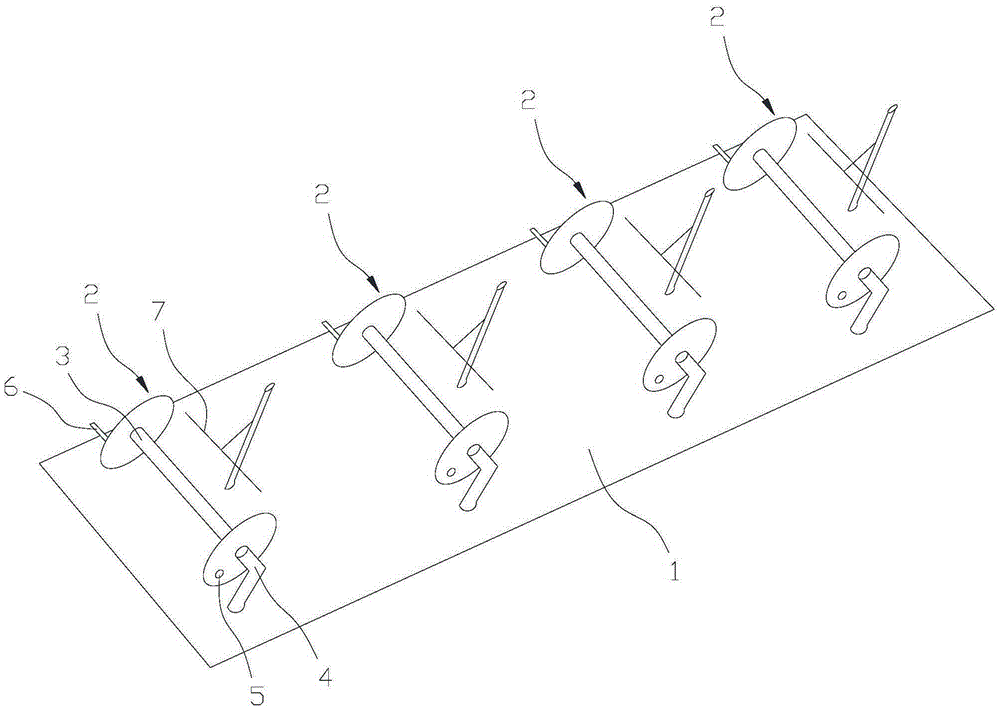

[0010] to combine figure 1 As shown, the combined ground terminal includes a ground base 1. A number of winding supports 2 are evenly arranged on the grounding base 1, and each winding support 2 is arranged in a straight line, and the grounding wire is connected to each winding support 2, which is neat and orderly. Each winding support includes a winding wheel 3 and a support shaft 4 . The support shaft 4 is L-shaped, the vertical section of the support shaft 4 is connected to the grounding base 1, the winding wheel is sleeved on the horizontal section of the support shaft 4, and can rotate around the support shaft 4, which is convenient for winding and storing the grounding wire , Keep the grounding wires clean and orderly. Both the ground base 1 and the support shaft 4 are supported by metallic conductive materials, such as iron, copper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com