A method for evaluating the connection relationship between oil wells

A technology of connection relationship and evaluation method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting the normal operation of oilfield production, difficult implementation, high cost, etc., to achieve low cost and wide reservoir range , high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

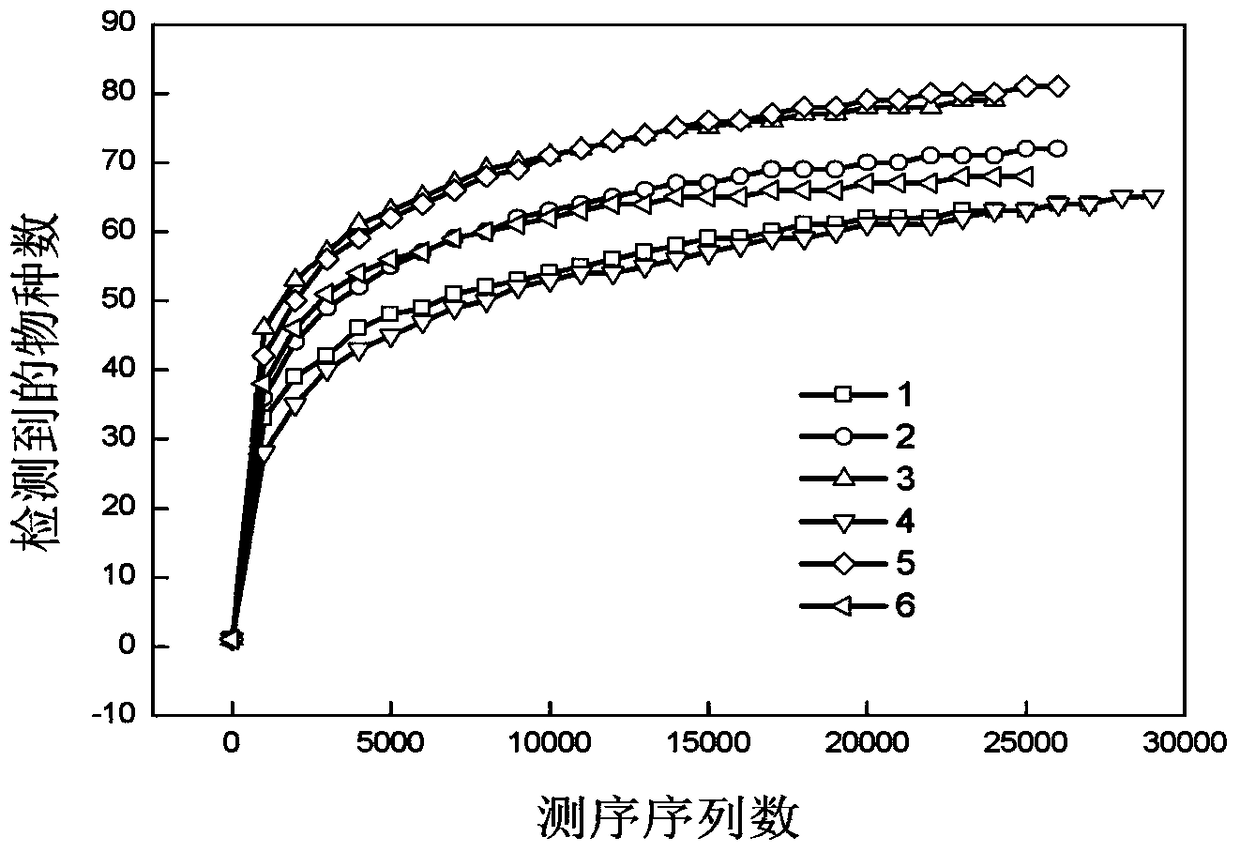

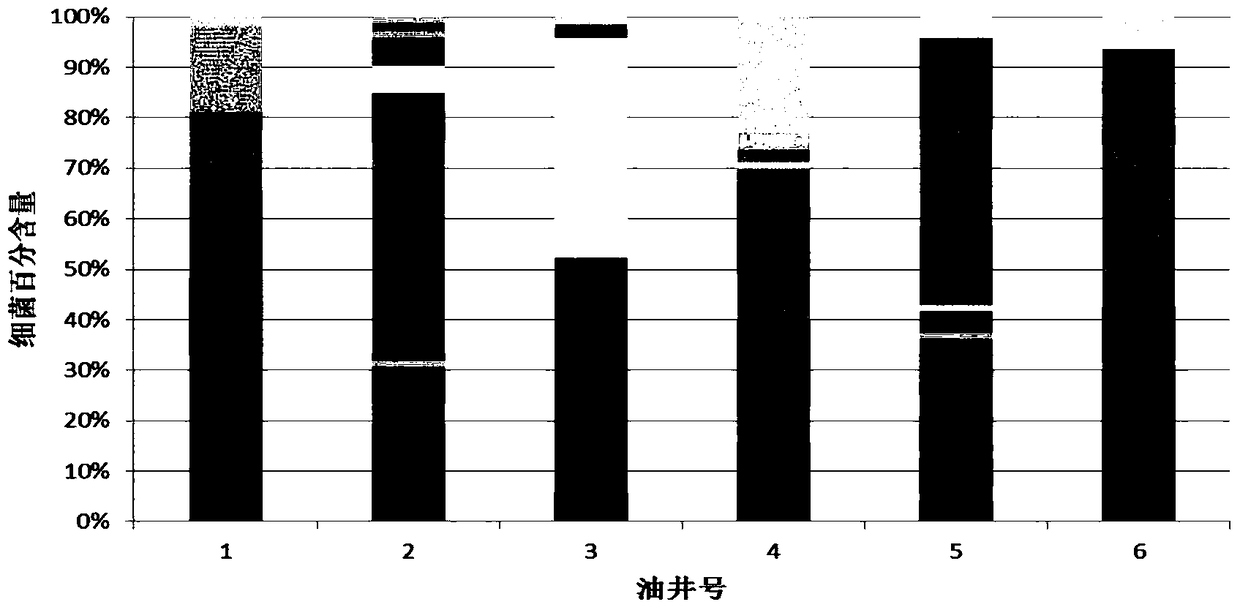

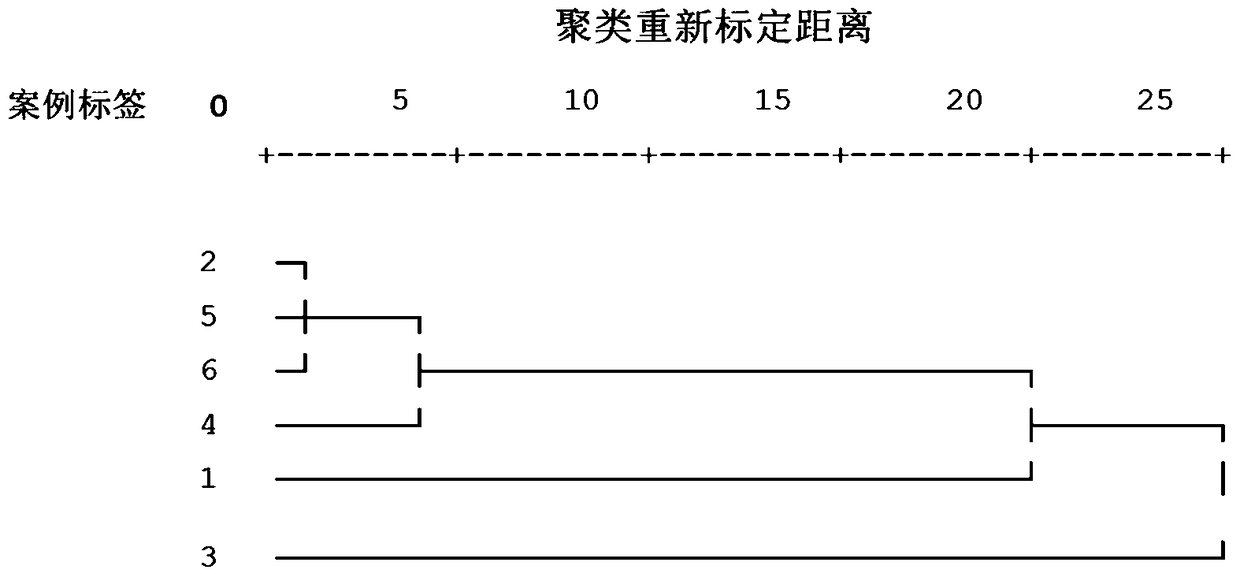

Embodiment 1

[0036] Block F of Shengli Oilfield is a water drive fault block reservoir, with 2 injections and 6 productions, reservoir temperature 63°C, reservoir pressure 10MPa, burial depth 1173m-1230m, porosity 31.5%, recoverable reserves 5.6×10 4 t, the viscosity of crude oil is 1885mPa.s, and the salinity of formation water is 14767mg / L; at present, there is a problem of uncoordinated injection and production in this block, and a production well is going to be transferred to injection, so it is necessary to understand the connection relationship between the six oil wells in this block , implementing the concrete steps of the present invention is:

[0037] (1) On-site sampling

[0038] Sterilized glass bottles with rubber stoppers and screw caps were used to drain 10L of production fluid in the pipeline before taking production fluid samples at the wellheads of the oil wells. The production fluid samples were taken from the wellheads of 6 oil wells, numbered as oil wells 1 to 6, each ...

Embodiment 2

[0051] A block M in Shengli Oilfield is located on the high point of the fault zone in the sag of a complex fault reservoir. 5 t, the formation water salinity is 12560mg / L. There are 6 oil wells in this block, of which No. 3 oil well is located in the west of the fault zone, and the other 5 oil wells are located in the east of the fault zone. The current geological analysis data of this block shows that the fault zone is not connected. The specific implementation steps of implementing the present invention are:

[0052] (1) On-site sampling

[0053] Use sterilized glass bottles with rubber stoppers and screw caps. Before taking production fluid samples at the wellheads of the oil wells, 20L of production fluids in the pipeline should be emptied. The production fluid samples were taken from the wellheads of 6 oil wells, numbered as oil wells 1 to 6, each The sampling volume of the well is 30L, and the production fluid will be taken to the sample and sealed at 4°C, and will be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com