Controlling method of plugging machine

A control method and technology of a chip inserter, which are applied in electrical program control, program control in sequence/logic controllers, sustainable manufacturing/processing, etc., can solve the problem of occupation of human resources, uneven force, and easy generation of dark lines. and other problems, to achieve the effect of good reliability, sensitive reflection and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

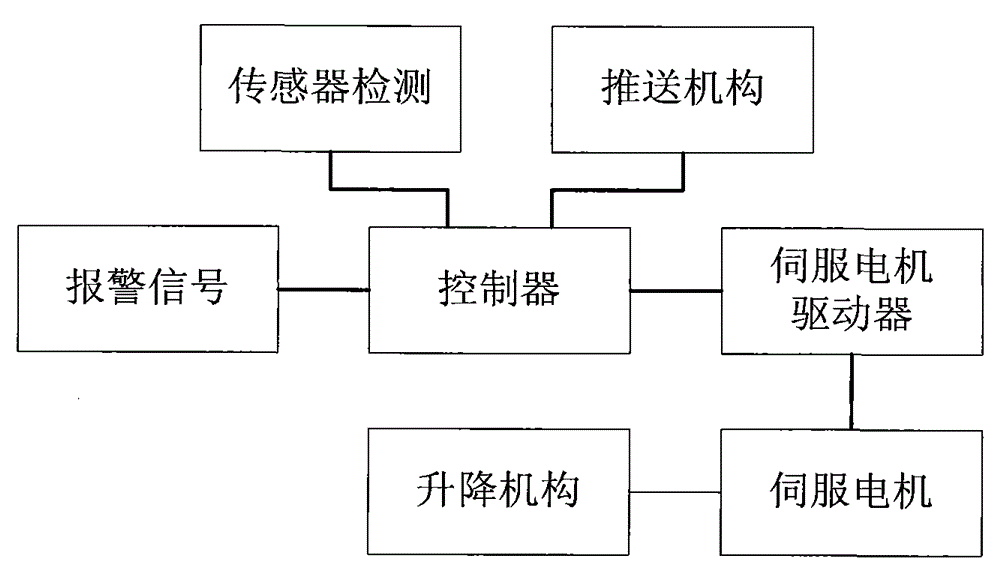

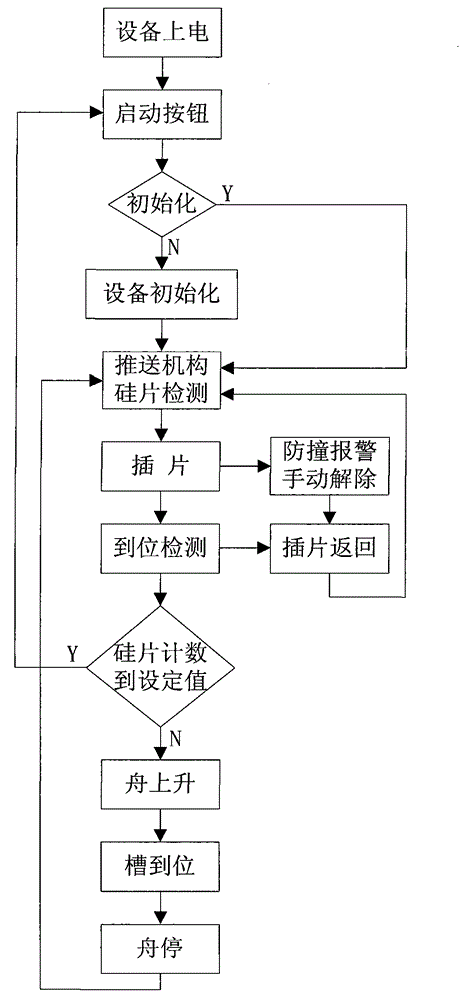

[0017] Such as figure 2 The flow chart of the control system shown is the logical action relationship of the control method, and the automatic inserting function of the inserting machine can be realized by combining the hardware parts such as the controller and the sensor. The specific implementation is as follows:

[0018] 1. Unit 1 is a PLC, and the controller itself is equipped with multi-point digital I / O ports and an extended position control unit. According to the technical requirements of the equipment, allocate digital I / O points, configure the command operation area and set the axis parameters in the position control unit, and then write the equipment control program. A self-resetting button is installed on the device, and its rising edge is detected to be valid in the program. When the quartz boat is installed and the button is pressed, the program starts to execute. First, the equipment initialization action: servo lock, search origin, logic control enable trigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com