Energy storage brick

A technology of energy storage bricks and working surfaces, applied in the field of heaters, which can solve the problems of low heat absorption efficiency, uneven heating of bricks, small contact area, etc., to slow down the excessive flow of air flow, good energy storage effect, and heat conduction and the effect of uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

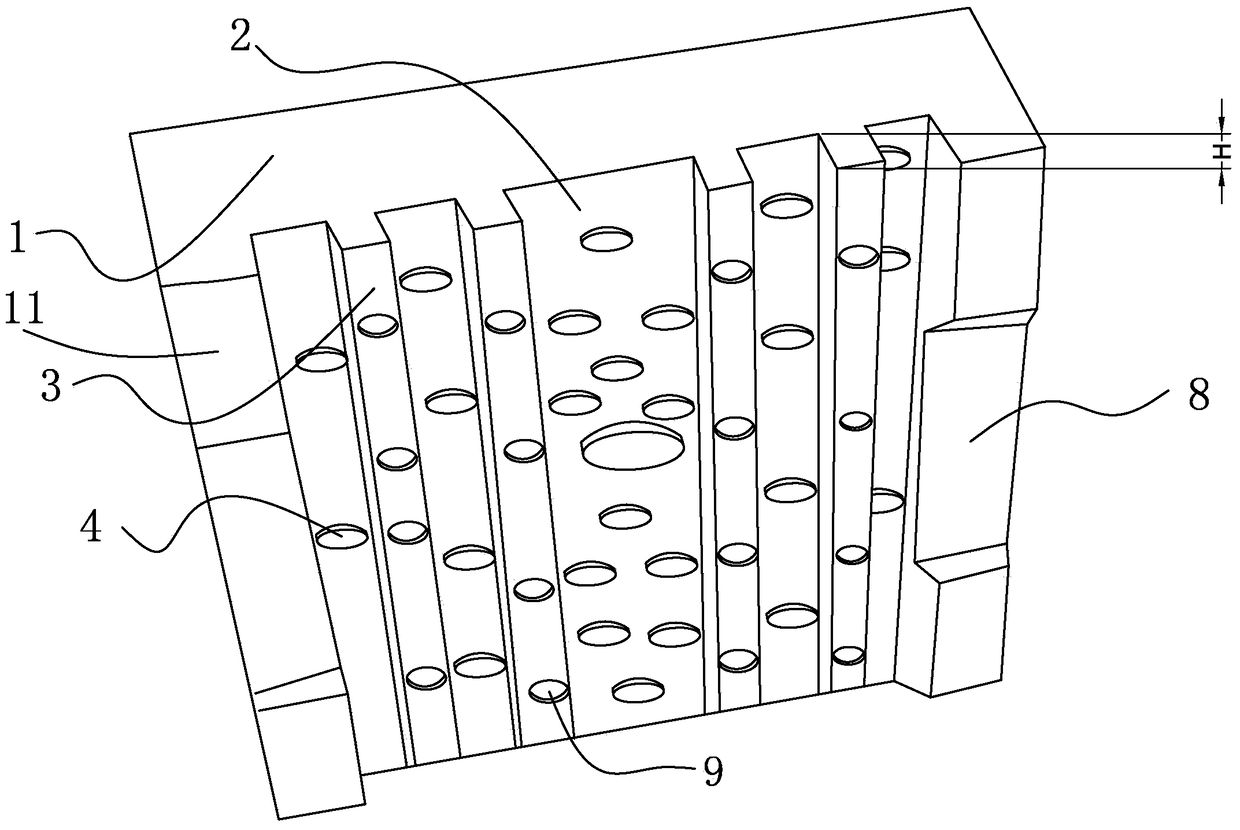

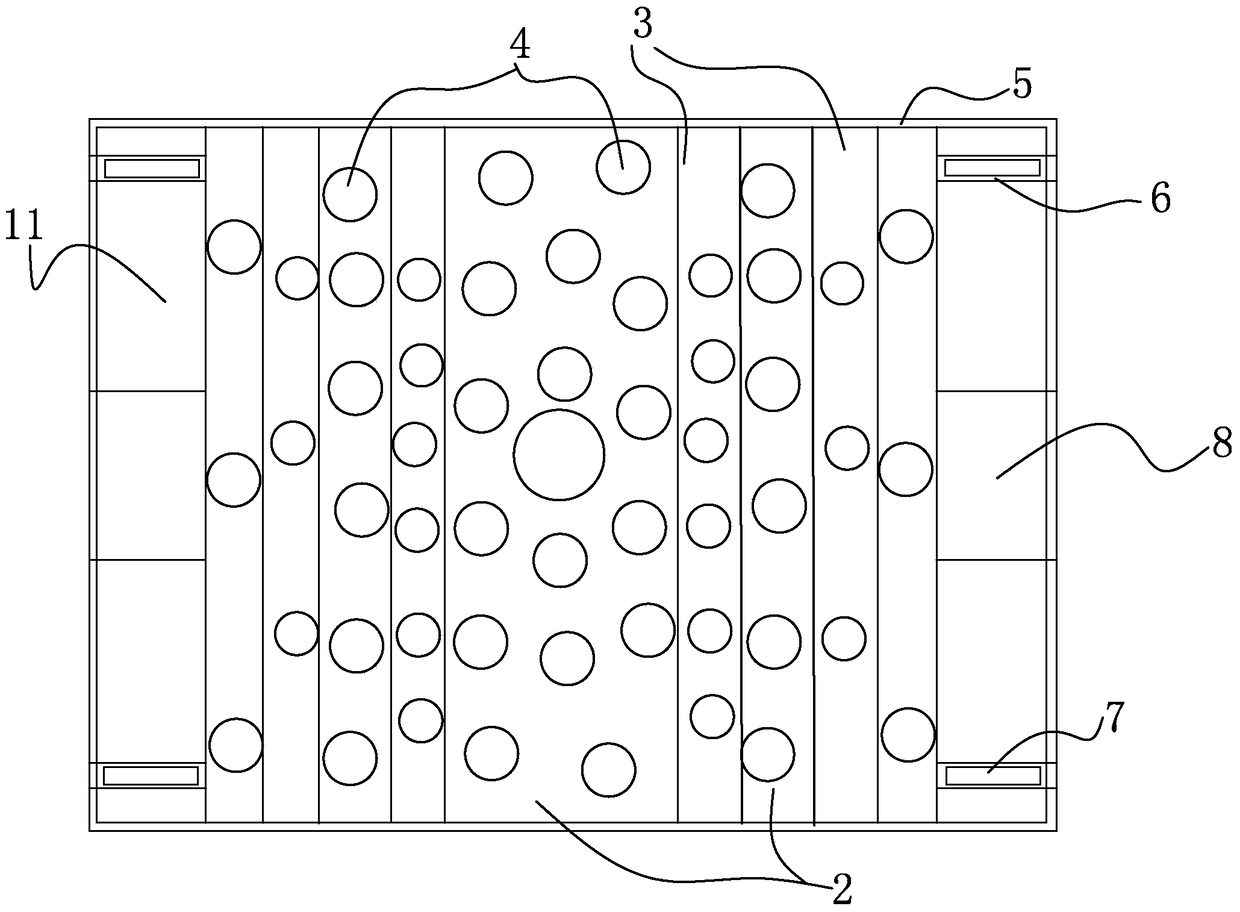

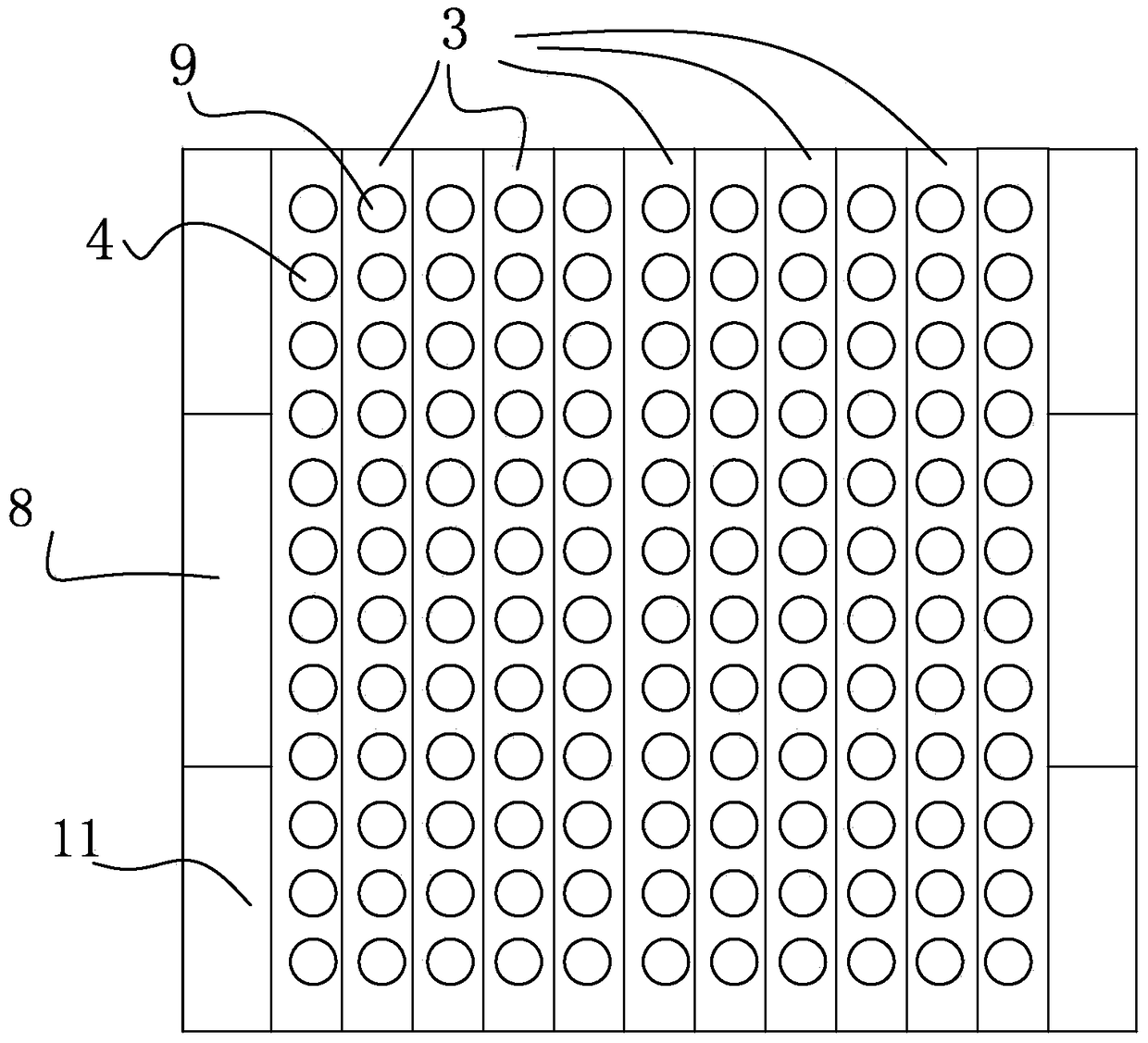

[0031] Such as Figure 1-2 As shown, the energy storage brick is a brick body 1 with a symmetrically arranged hexahedron structure, one of which is provided with a concave working surface 2, and the concave working surface is provided with a plurality of vertical bars 3 arranged in parallel. There are grooves 9. The groove 9 is preferably cylindrical or rounded. As an option, the height H of the vertical bar can be flush with the upper surface of the plane 11 where it is located.

[0032] Protrusions 4 are provided between the vertical bars. The shape of the protrusions is preferably cylindrical, and its height h2 above the concave working surface is lower than the height H of the convex strips, that is, it is lower than the concave working surface and its plane 11. the distance between. The height setting is preferably selected such that the depth h2 of the groove is 1 / 2 of the height H of the vertical bar, and the height h2 of the protrusion is 2 / 3 of the height H of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com