Independent high beam LED automobile lens

A car and lens technology, applied in the field of independent high-beam LED car lenses, can solve problems such as low brightness and insufficient irradiation distance, and achieve the effects of fast lighting speed, long service life, and reduced lens volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawings and embodiments thereof.

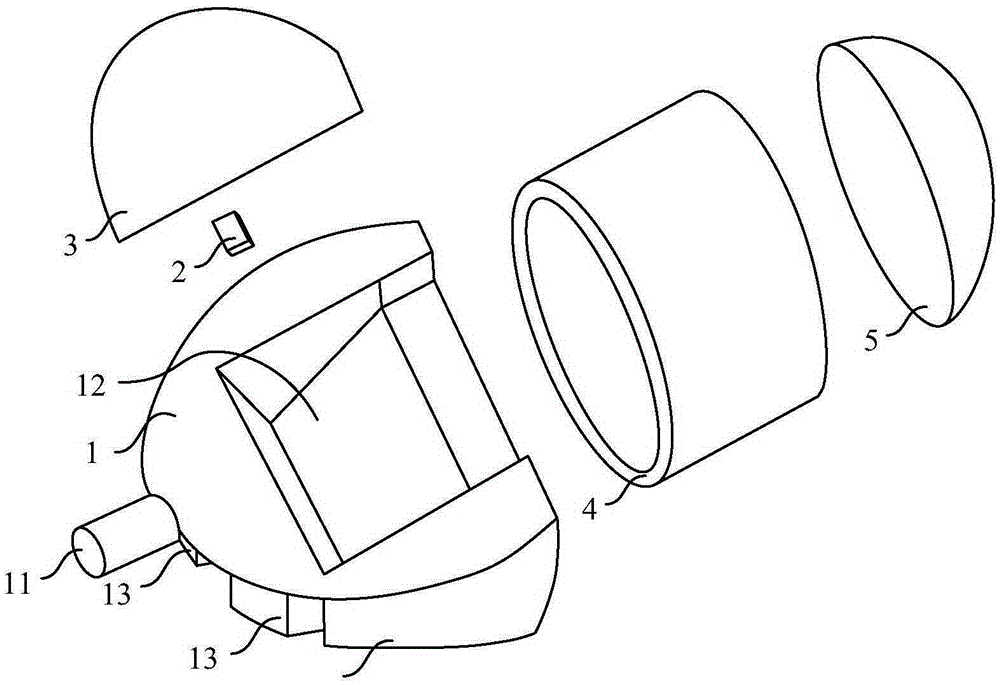

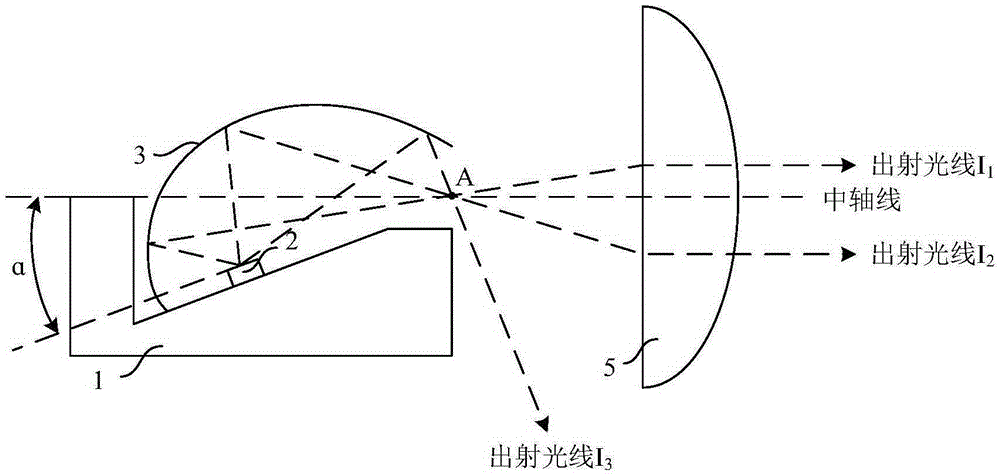

[0024] refer to figure 1 , the LED automotive lens of the present invention includes a heat dissipation bracket 1, a lamp bead 2, a reflector 3, a lens bracket 4 and a lens 5; wherein: the lamp bead 2 is arranged in the reflector 3, and is installed on the heat dissipation bracket together with the reflector 3 1, a lens holder 4 is installed on the front end of the cooling bracket 1, and a lens 5 is installed on the front end of the lens holder 4.

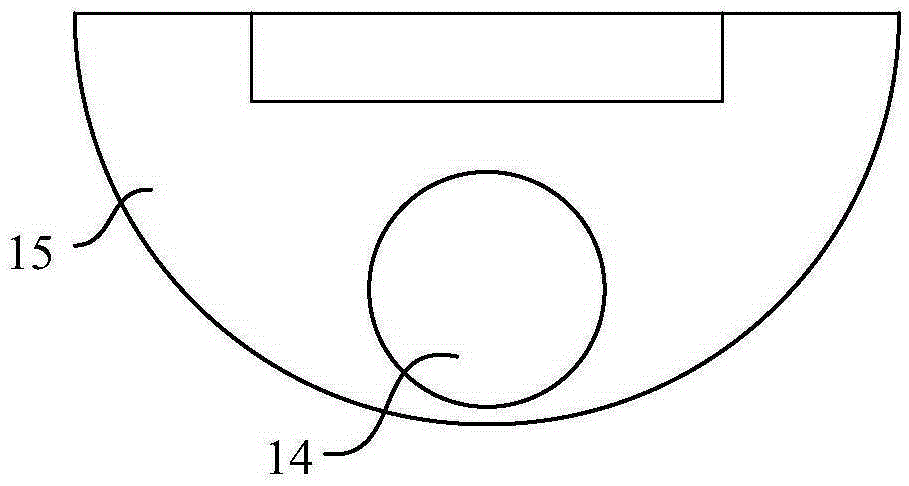

[0025] refer to figure 1 and figure 2 , the heat dissipation bracket 1 includes a mounting handle 11, a mounting groove 12, a cooling fin 13, a cooling fan 14 and a lens bracket mounting bracket 15; the mounting handle 11 is located at the tail of the cooling bracket 1, and is used for connecting the LED automobile lens of the present invention to the The car body is fixed; the installation groove 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com