Locking pin assembly and method of use thereof

A technology of locking pins and components, applied in the direction of connecting components, thin-plate connections, bolts, etc., can solve the problems of high-end fasteners with high technical requirements, difficult processes, complex structures, etc., and achieve reliable movable link performance and fastener characteristics , good workmanship, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it is not used as any limitation basis for the present invention.

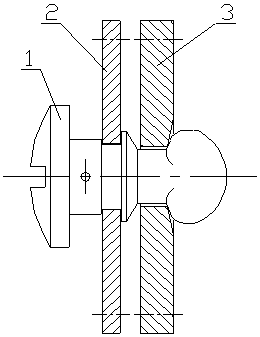

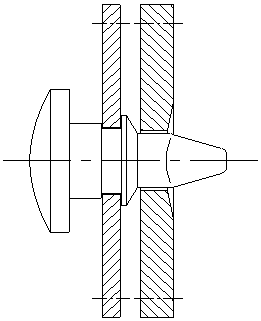

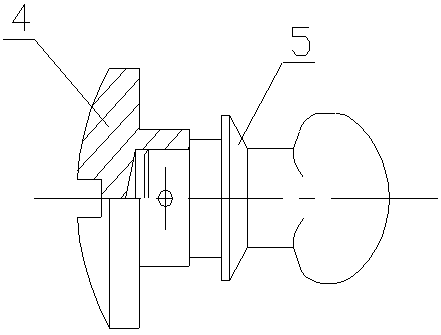

[0033] A new locking pin assembly, including a mounting plate 2, a buckle plate 3, a driving head 4, a locking key 5 and a rivet 6;

[0034] The aforementioned mounting plate 2 includes: mounting plate hole 40, mounting plate plane I 41, mounting plate plane II 42, mounting plate connection hole 43 and mounting plate side 44; mounting plate hole 40 and the small cylindrical surface 10 of the drive head adopt clearance fit, and the fit clearance is 0.05 ~0.1mm, to ensure that there is no blockage when the mounting plate hole 40 and the small cylindrical surface 10 of the drive head work;

[0035] The mounting plate 2 is made of carbon structural steel 20# steel, which has strong versatility and low price, and meets the requirements of use.

[0036] The aforementioned pinch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com