Transverse Stiffening Device for Corrugated Steel Web Composite Beams

A corrugated steel web and strengthening device technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the height-to-thickness ratio of the web cannot be too large, the position of the steel beam is difficult to adjust, and the welded parts are easy to rust, etc. , to achieve the effects of fast construction, improved shear resistance, and overall torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

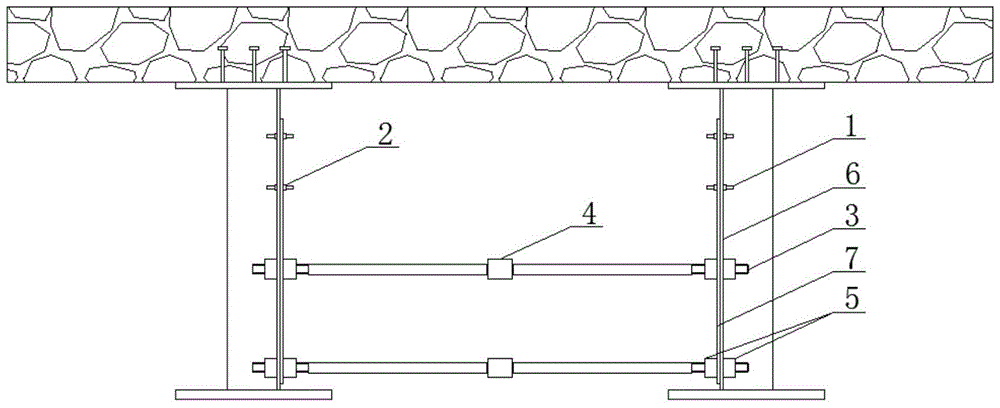

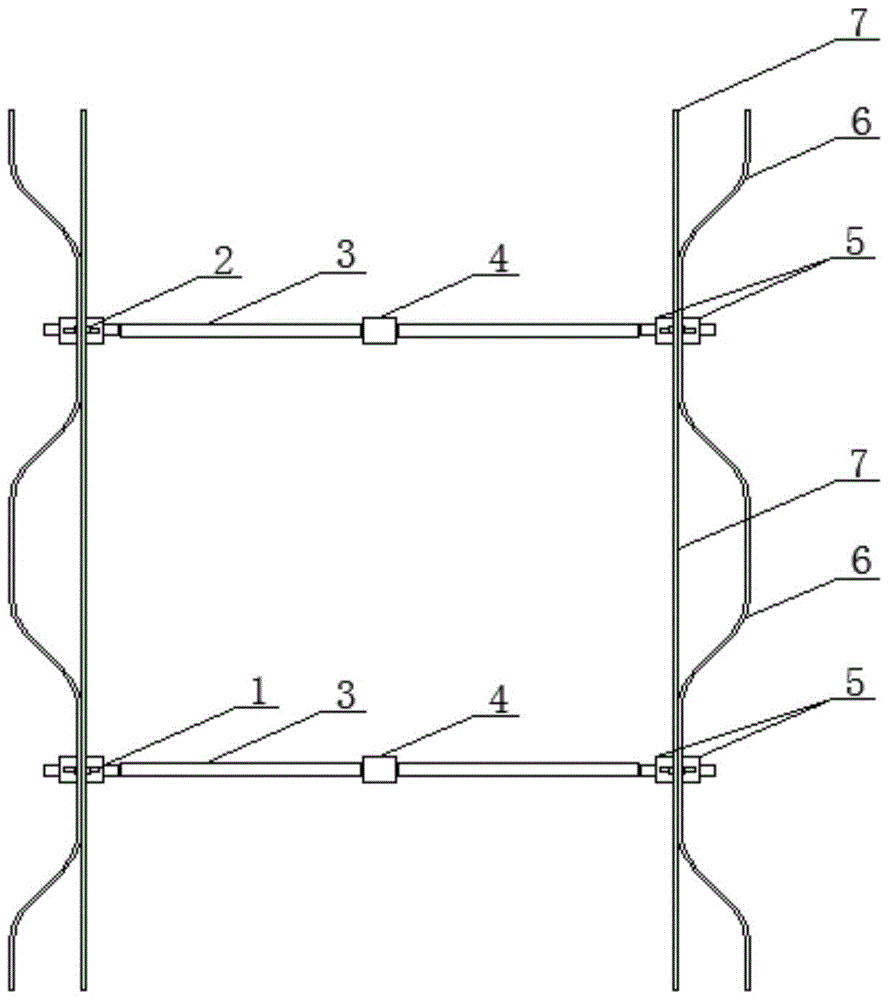

[0023] In order to further illustrate the technical means and functions adopted by the present invention to achieve the predetermined invention goal, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] like Figure 1~5 The schematic structural diagram of the lateral strengthening device of the corrugated steel web composite beam of the present invention and the partially enlarged schematic diagram of the main components include a stud 1, a hex nut 2, a threaded steel rod 3, a large threaded sleeve 4, and a small threaded sleeve 5. Corrugated steel web 6 and flat plate 7.

[0025] Wherein the vertical steel plate of the H-shaped steel is a corrugated steel web 6, and a flat steel plate 7 is fixed on the relative inner side of the corrugated steel web 6, and the corrugated steel web 6 and the flat steel plate 7 are connected by a stud 1, Both ends of the double-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com