A three-dimensional laser embroidery machine

An embroidery machine and laser technology, which is applied in the field of embroidery machines, can solve problems such as complicated processing technology, affecting quality, and increasing cutting processes, and achieve the effects of reducing complexity, improving quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

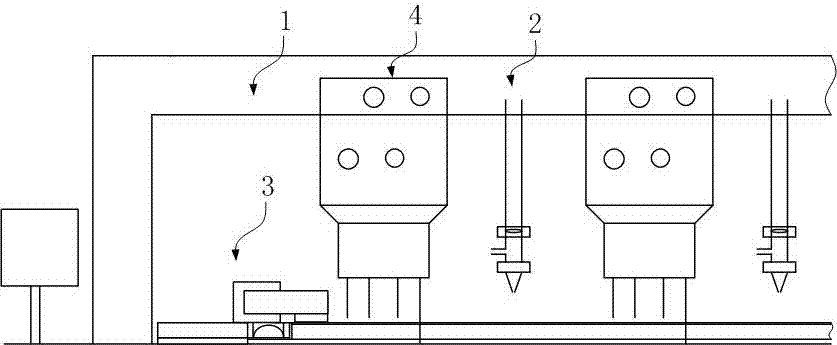

[0029] refer to figure 1 A schematic diagram of the overall structure of this embodiment is shown.

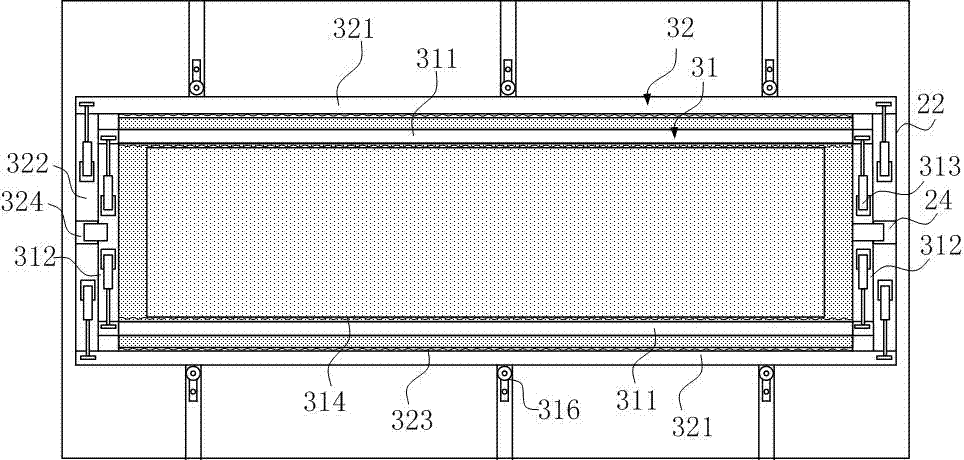

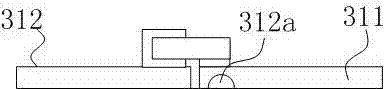

[0030] A three-dimensional laser embroidery machine according to an embodiment of the present invention comprises a workbench and a plurality of laser cutting heads 2 and embroidery heads 4 arranged at equal intervals on the beam 1 of the workbench, and a workbench that is slidably arranged under the laser cutting head 2. Double-layer cloth locking mechanism on the tabletop3.

[0031] The embroidery machine head 4 embroiders the double-layer cloth on the double-layer cloth locking mechanism 3;

[0032] The laser cutting head light source is driven by a high-voltage stable circuit CO 2 The laser is generated to cut the embroidery of the upper fabric of the double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com