Shaft sleeve transportation handcart

A trolley and bushing technology, applied in multi-axle trolleys, trolleys, transportation and packaging, etc., can solve the problems of secondary pollution, affecting the assembly quality of bushing parts, parts bumping, etc., to improve transportation quality, save manpower and material resources, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

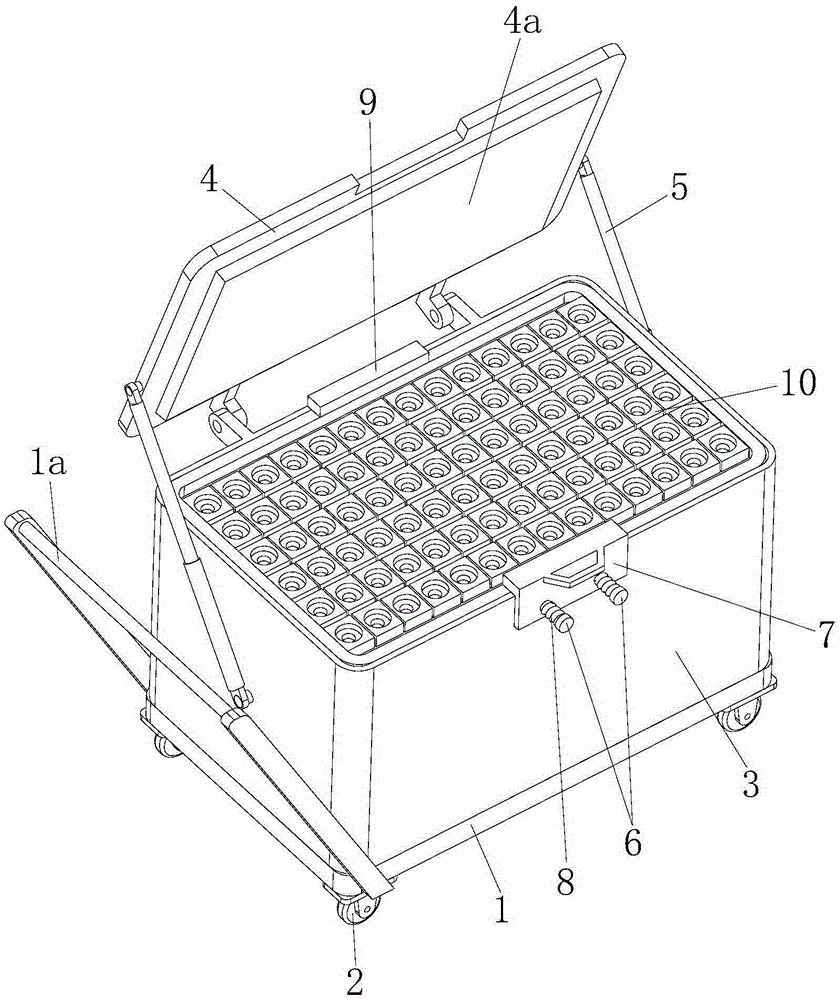

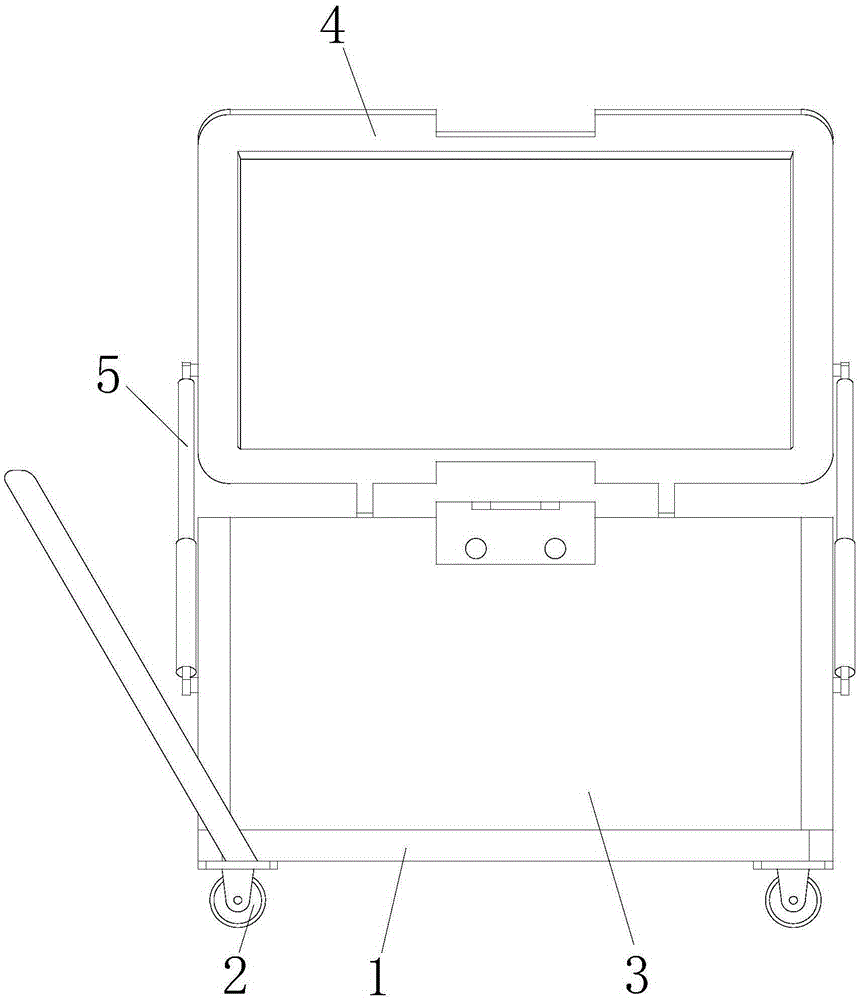

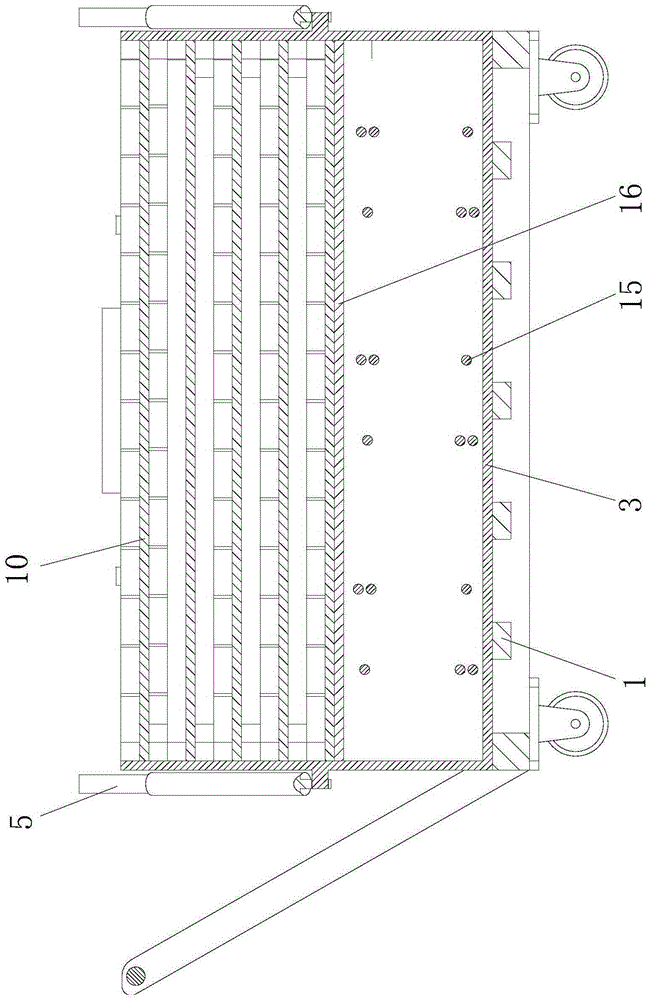

[0017] like Figure 1 to Figure 5 Shown, a kind of axle sleeve transport trolley comprises frame 1, and the lower end of described frame 1 is evenly provided with moving wheel 2, and the left side of frame 1 is provided with push rod 1a, and the upper end of frame 1 is fixed with box body 3, and described The top of the box body 3 is fixed with a top cover 4 by means of hinges, the left and right ends of the box body 3 are fixed with gas support rods 5 by means of hinges, and the top ends of the gas support rods 5 are fixed by means of hinges On the top cover 4, the front side of the upper end surface of the box body 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com