Adjustable automatic stamping machine

An automatic stamping machine, adjustable technology, applied in printing, stamping, etc., can solve the problems of inconvenient popularization, no products, large quantities, etc., and achieve the effect of improving work efficiency, reducing labor intensity, and high stamping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below by means of the accompanying drawings and examples.

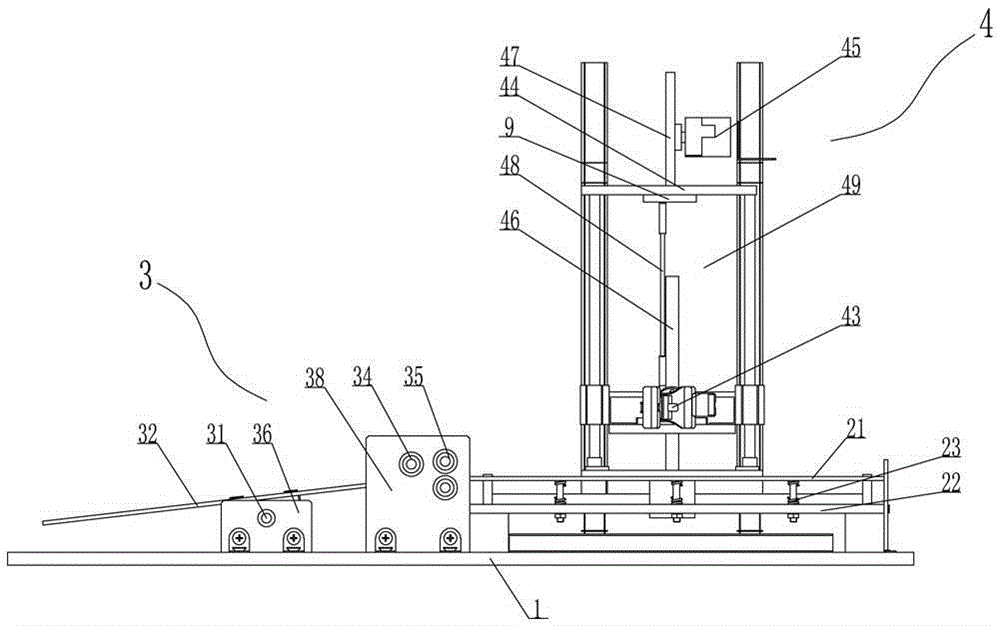

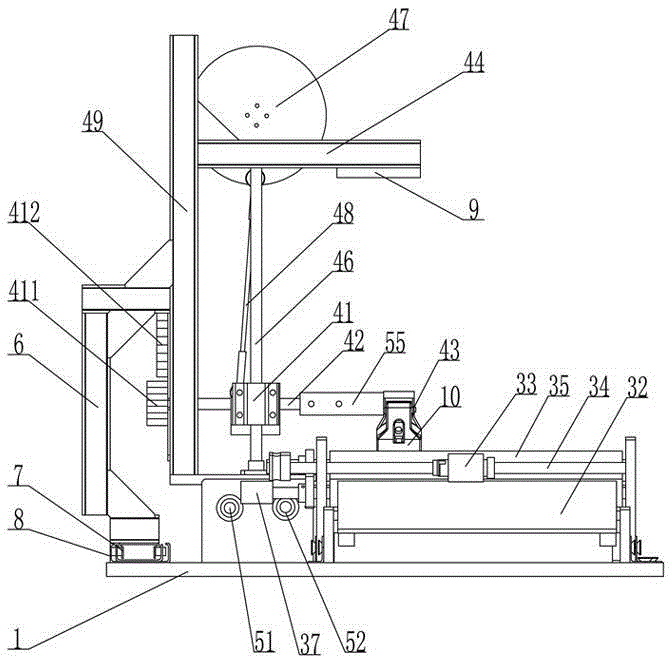

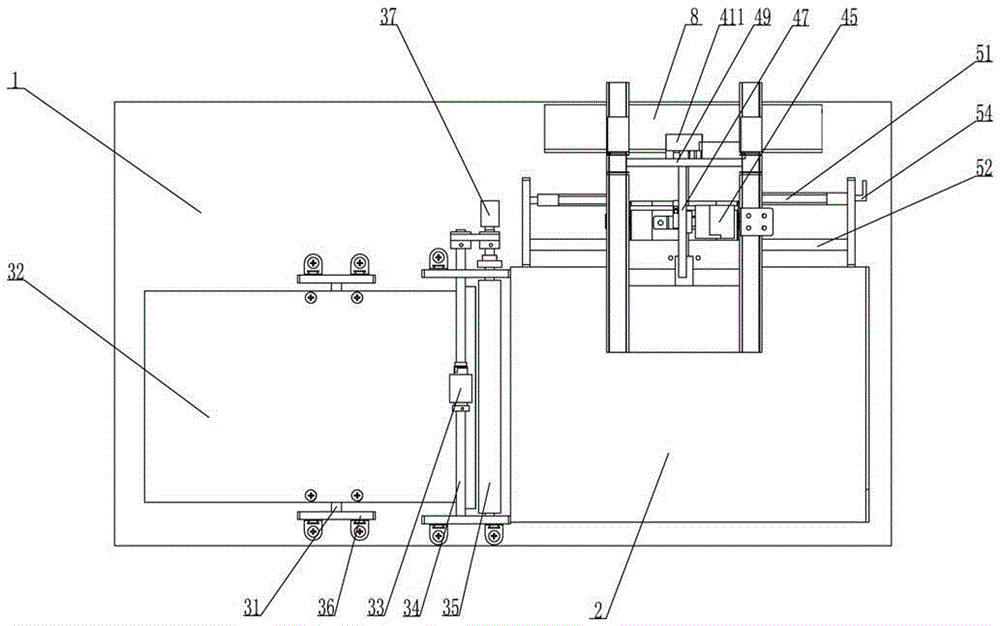

[0022] Such as Figure 1 to Figure 6 Shown: an adjustable automatic stamping machine, including a stamping machine base 1. The stamping machine base 1 is provided with a stamping platform 2, and one side of the stamping platform 2 is provided with a paper conveying mechanism 3. The paper outlet of the paper conveying mechanism 3 is facing the stamping platform 2, and the rear side of the stamping platform 2 An automatic seal mechanism 4 is provided. The automatic stamping mechanism 4 comprises a movable block 41, on the movable block 41, a rotating shaft 42 is horizontally arranged, and one end of the rotating shaft 42 extends to the top of the stamping platform 2 and is equipped with a gripper 43 for clamping the stamp 10, and the gripper 43 The top of the ink pad box fixing plate 44 is provided. The automatic stamping mechanism 4 also includes a lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com