A mechanism for the top plate of an injection mold to drive the screw to rotate and eject the mold

A technology that drives the screw and rotates out, which is applied in the field of the mechanism of the top plate of the injection mold driving the screw to rotate and eject the mold. It can solve the problems of high manufacturing and maintenance costs, strains, and low product quality, so as to improve the molding quality, manufacturing and maintenance costs. Low, simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

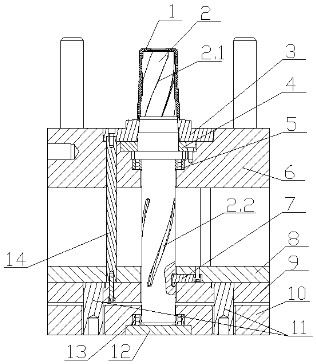

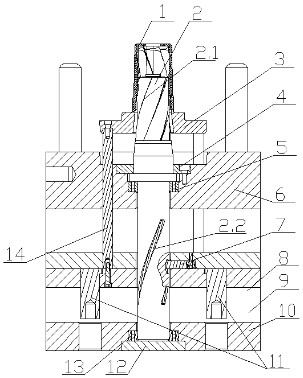

[0021] refer to figure 1 with figure 2 As shown, a mechanism for the top plate of an injection mold to drive the screw to rotate and eject the mold, including a product 1, a screw core 2, a push plate 3, a pressure plate 4, a first bearing 5, a movable template 6, a driving block 7, an upper top plate 8, a lower Top plate 9, bottom plate 10, pull reset 11, backing plate 12, second bearing 13 and first push rod 14, the upper part of the screw core 2 has a spiral undercut 2.1, which is attached to the inner side of the product 1, and the screw type There is a helical groove 2.2 on the lower part of the core 2, the helical pitch is the same as that of the helical undercut 2.1, and the helical groove 2.2 cooperates with the driving block 7.

[0022] The driving block 7 is fixed on the upper top board 8 and attached to the lower top board 9 .

[0023] The inside of the push plate 3 cooperates with the screw core 2, the push plate 3 has protruding features and fits with the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com