High-precision glass fiber plastic-coating iron die

A high-precision, plastic-wrapped technology, applied in the coating and other directions, can solve the problems of easy to top damaged products, decreased toughness, increased brittleness, etc., to achieve the effect of good fixing accuracy, ensuring quality, and not easy to top damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

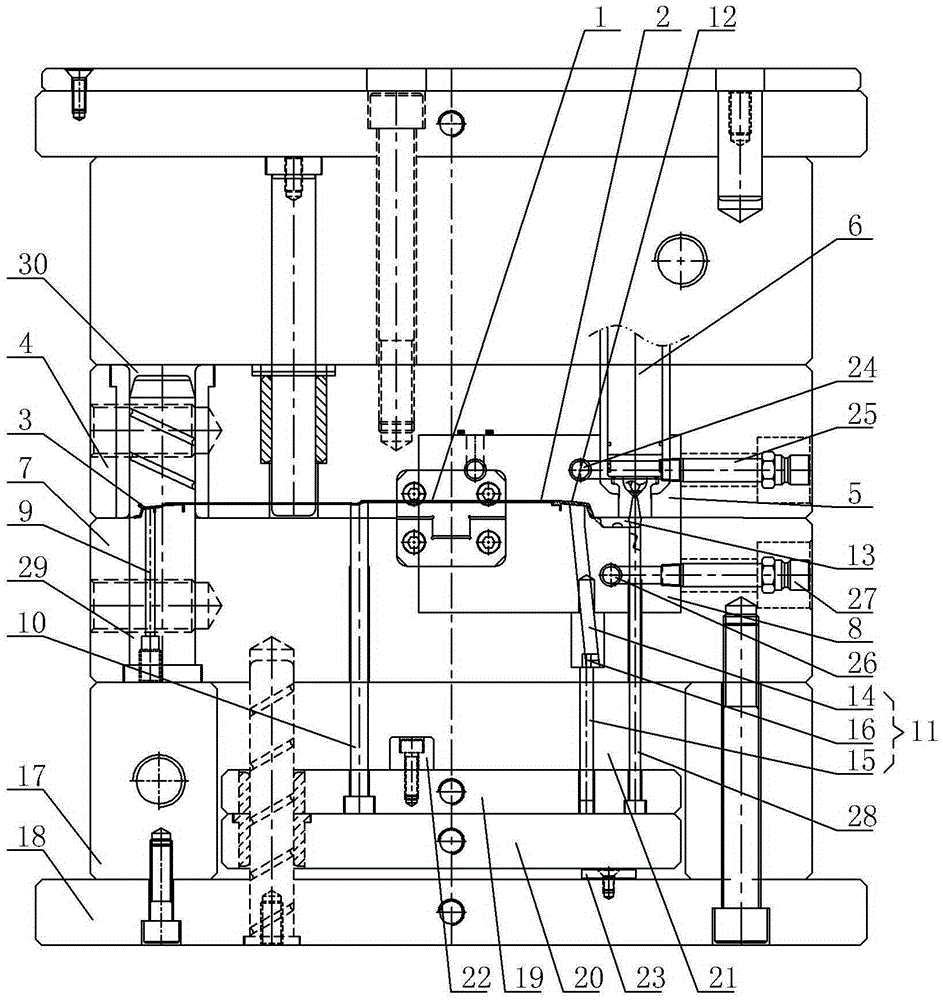

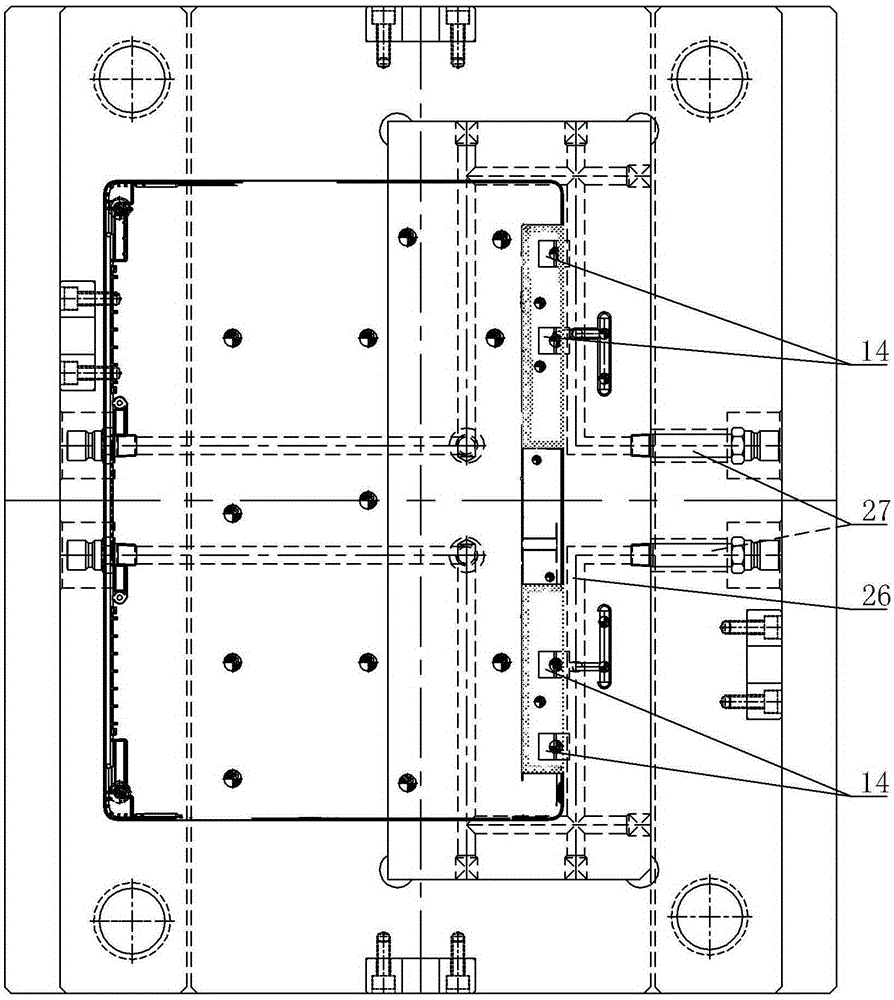

[0020] A high-precision glass fiber plastic-coated iron mold, see figure 1 , figure 2 : It includes a female mold part and a male mold part, and a magnesium-aluminum alloy product 1 is arranged in the middle of the female mold part and the male mold part. One side of the magnesium-aluminum alloy product 1 is the side to be molded 2, and the other side is the positioning side 3. The female mold part includes the female template 4, the female mold core 5, and the hot nozzle runner 6, the male mold part includes the male template 7, the male mold core 8, and the thimble, and the male mold part is provided with an inlay corresponding to the positioning side of the magnesium aluminum alloy product 1. The pin structure 9, the top of the pin-studded structure 9 is installed on the lower end surface of the positioning side 3 of the magnesium-aluminum alloy product 1, the thimble includes a magnesium-aluminum alloy product thimble 10, and a plastic-packed structure thimble 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com