Glass touch screen machining machine tool

A technology for processing machine tools and touch screens, applied in the field of CNC machine tools, can solve the problems of inconvenient use of protective doors and low processing efficiency of glass touch screens, etc., and achieve the effects of good shock absorption, small space occupation, and strong mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation process and implementation effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

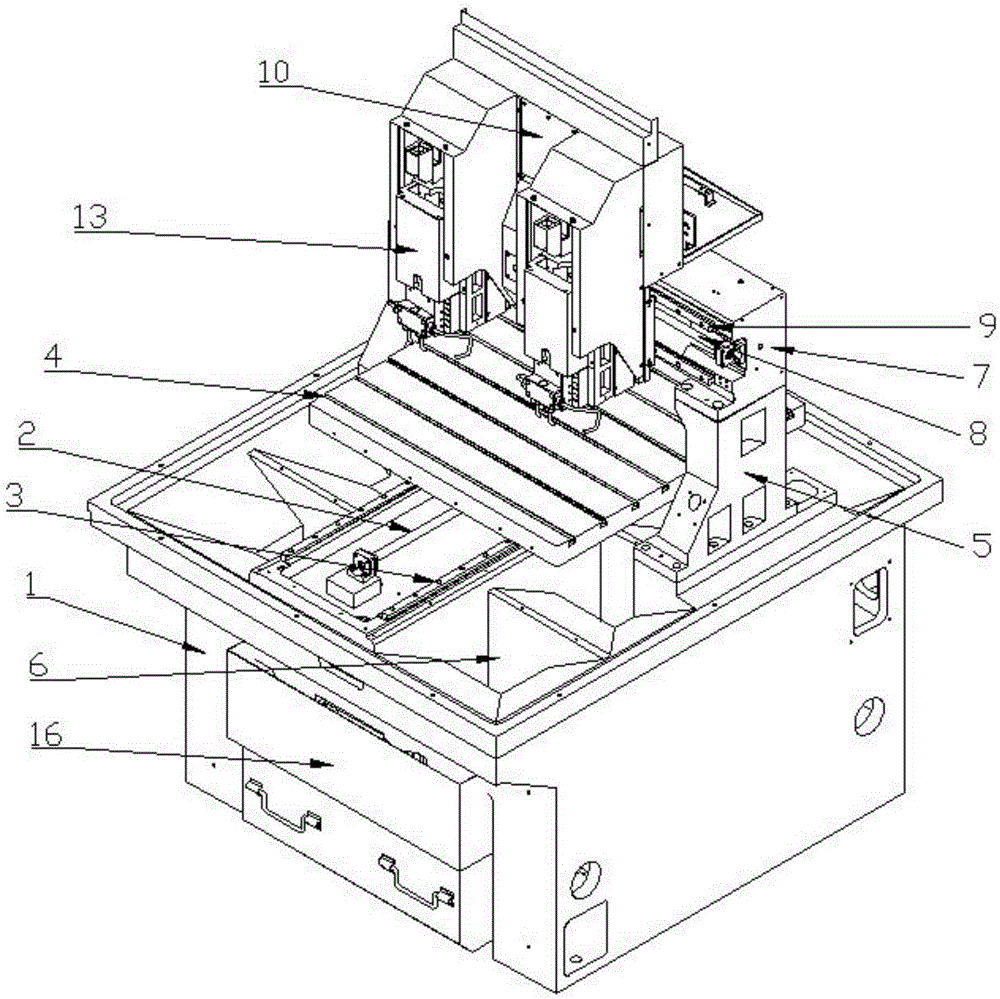

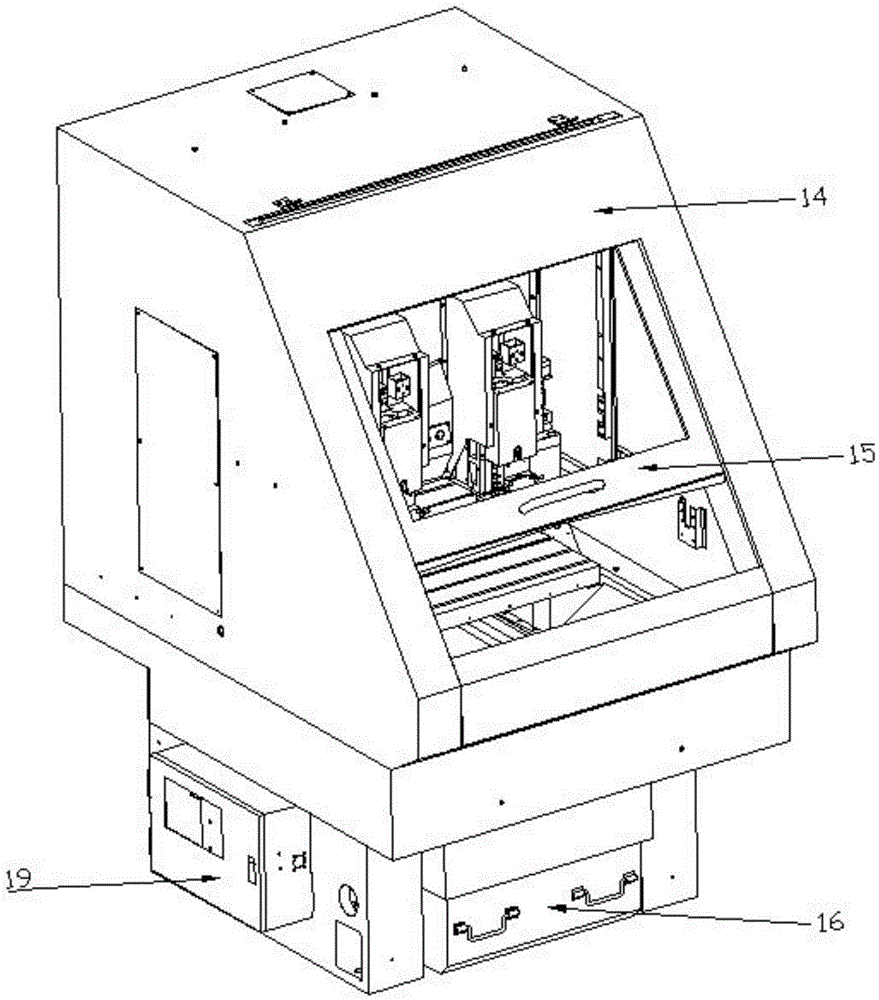

[0032] A glass touch screen processing machine tool adopts a gantry body, and the optical machine base is arranged above the gantry body. Such as figure 1 and figure 2 As shown, it includes an optical machine base 1, a spindle assembly 13, and a protective cover. The optical machine base 1 is provided with a worktable 4, and the worktable 4 is provided with a spindle assembly. The spindle assembly 13 includes at least two spindles. , in the embodiment of the present invention, preferably double spindles, the spindles are connected with tools, and the tools of the spindles can be changed by pressing the tool change button 17 .

[0033] The glass touch screen processing machine tool also contains pneumatic components 19, such as figure 2 As shown, the pneumatic assembly 19 is arranged on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com