Suspension telescopic cylinder and mechanical arm fast installing and uninstalling system under nuclear radiation environment

A robotic arm and telescopic cylinder technology, which is applied in the field of hanging telescopic cylinders and robotic arm quick disassembly and assembly systems, can solve the problems of manually pulling out cable joints, intricate pipelines, and complex structural design, and achieve shortened maintenance, simple maintenance, and improved performance. The effect of disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

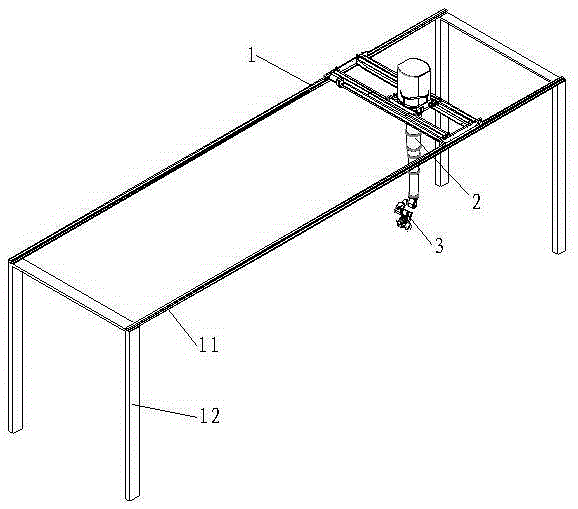

[0031] A system for quick disassembly and assembly of a hanging telescopic tube and a mechanical arm in a nuclear radiation environment, the quick disassembly system mainly includes a driving frame 1, a telescopic tube device 2, a manipulator 3 and a disassembly device,

[0032] Wherein, the driving frame 1 is a large cubic frame structure, which is composed of a rectangular horizontal frame 11 and four supporting feet 12. The horizontal frame 11 is equipped with a guide rail 13 that connects two relatively long sides and can translate along the relatively long sides;

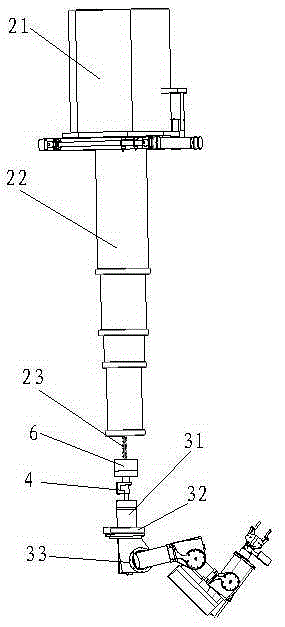

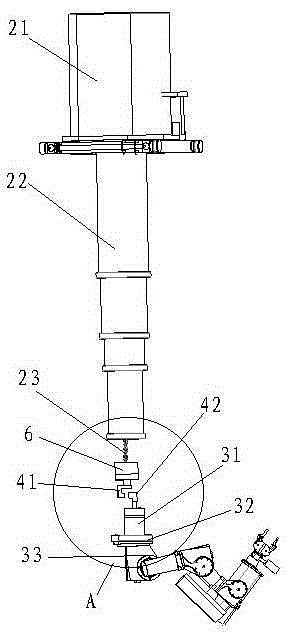

[0033] The telescopic tube device 2 mainly includes a fixed seat 21, a telescopic tube 22, a hoisting chain 23, a hoisting pulley and a pulley drive device. The fixed seat 21 and the telescopic tube 22 are fixedly connected from top to bottom and the two are connected internally. The fixed seat 21 is slidably erected. On the guide rail 13 of the horizontal frame 11, the telescopic tube device 2 is formed by supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com