Full-automatic pressing device for perforating bullets

A fully automated, perforating charge technology, applied in metal processing equipment, wellbore/well components, production fluids, etc., can solve the large technical gap, restrict production efficiency and product quality stability, and the automation level of press-fitting equipment is backward, etc. problems, to reduce the probability of occurrence, improve the efficiency of press-fitting and product quality stability, and achieve the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

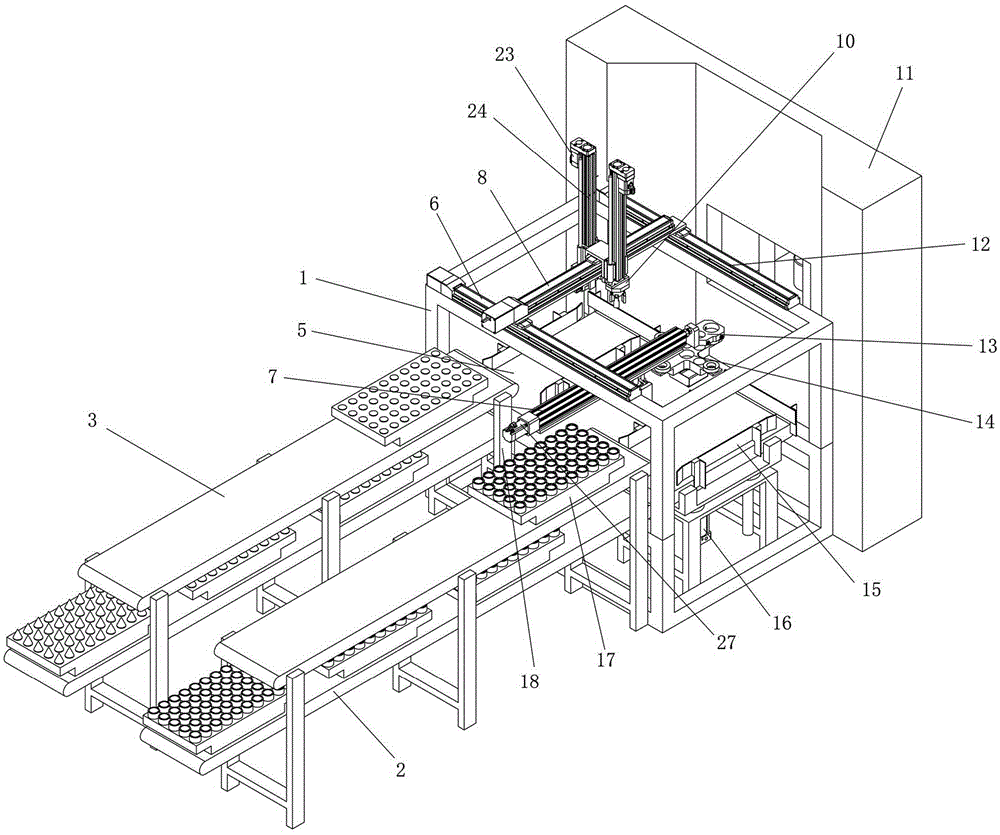

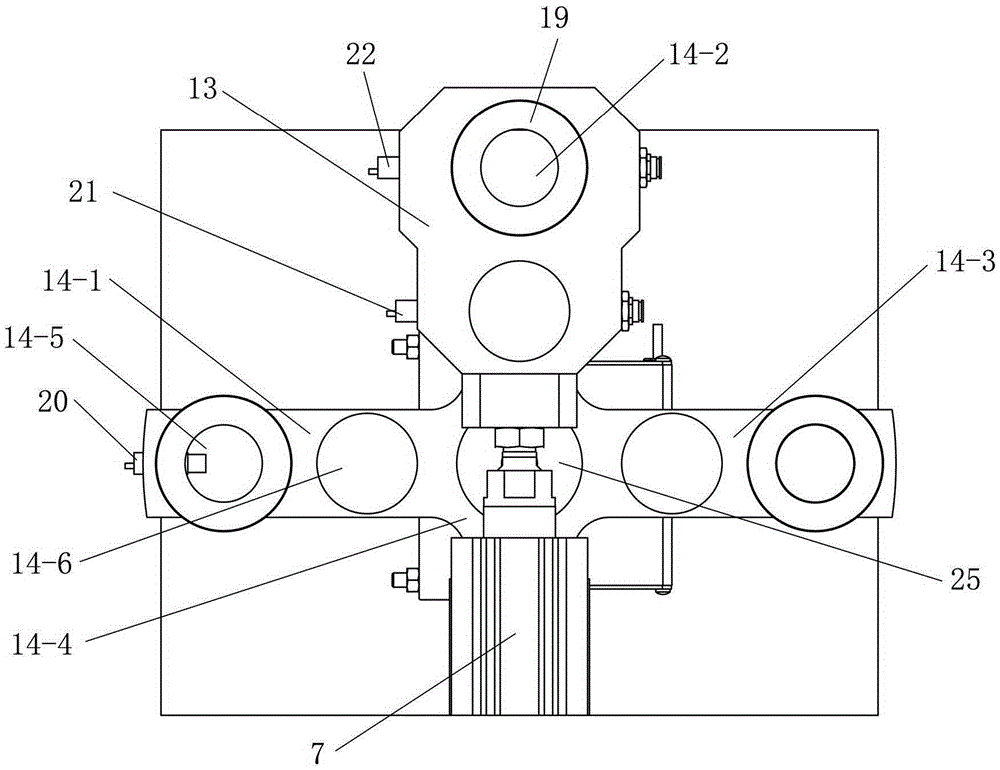

[0032] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout.

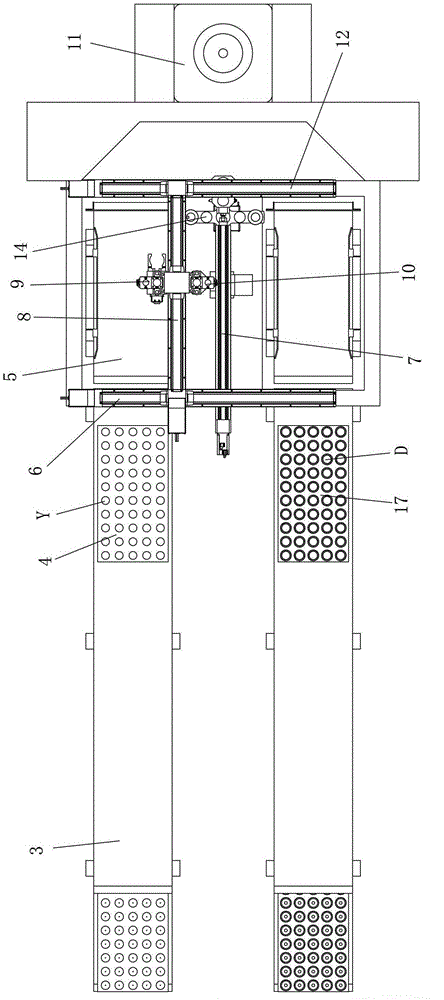

[0033] refer to Figure 1 to Figure 4 According to the present invention, the fully automatic press-fitting equipment mainly includes a frame 1, at least two sets of conveyor belts, a pick-up device and a control system.

[0034] The frame 1 can be made of various steel frames, etc., and is used to support the conveyor belt and the pick-up device.

[0035] The fully automated press-fitting equipment may specifically include two sets of conveyor belts to respectively convey the liner Y and the projectile body D used for press-fitting the perforating charge, wherein the projectile body D is a combination of explosives and shells. The structure of each group of conveyor belts is the same, and can include an upper conveyor belt 3, a lower conveyor belt 2 and a lifting conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com