Mutual inductor insulating oil degassing device and degassing method thereof

A degassing device and transformer technology, applied in chemical instruments and methods, liquid degassing, separation methods, etc., can solve the problems of increasing the difficulty of degassing, increasing secondary pollution, lowering the oil level, etc., to prevent secondary contamination, reduced exposure time, elimination of the effect of lower oil levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

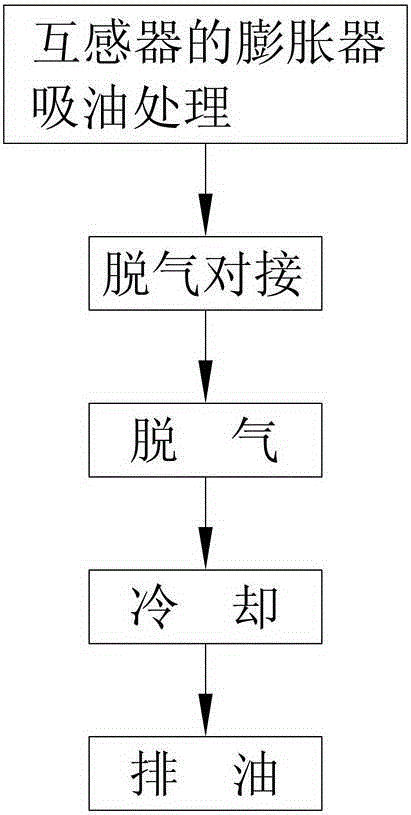

[0028] Such as figure 1 As shown, an embodiment of the transformer insulating oil degassing device of the present invention includes a vacuum flash tower 5 and an oil inlet pipeline 1 connected to the vacuum flash tower 5, an oil outlet pipeline 2, a drain pipeline 3 and an exhaust gas The pipeline 4, the oil inlet pipeline 1 and the oil outlet pipeline 2 are respectively connected with the transformer, the oil inlet pipeline 1 and the oil outlet pipeline 2 are provided with a bypass pipeline 6, and the oil outlet pipeline 2 is provided with a cooler 7. In this structure, before degassing, the oil outlet pipeline 2 can be docked with the vent plug on the upper part of the expander of the transformer, and the bypass pipeline 6 and the oil inlet pipeline 1 can be opened to absorb the insulating oil in the expander to prevent formal dega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com