Full-automatic pressure bearing pressure-free operation system of heat storage water tank of water heater

A hot water storage tank and operating system technology, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of shortened service life, water leakage, easy breakdown, etc., to reduce pressure and water discharge, improve safety performance, The effect of reducing leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

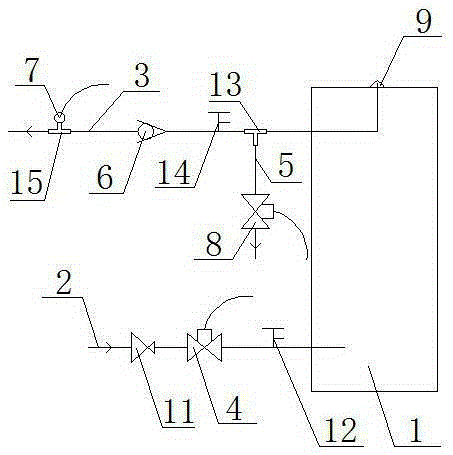

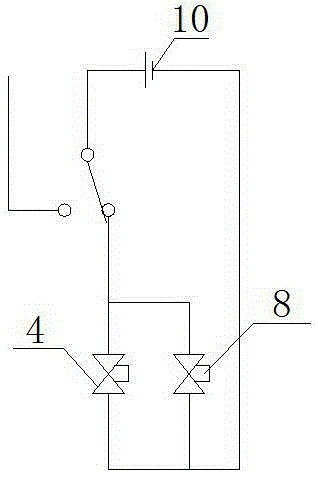

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a hot water storage tank 1. The outside of the hot water storage tank 1 is respectively connected with a cold water inlet pipeline 2 and a hot water outlet pipeline 3. The cold water inlet pipeline 2 is provided with a normally closed solenoid valve 4. The directions are sequentially connected in parallel with a pressure relief pipeline 5 , a series connection with a one-way valve 6 , and a parallel connection with a pressure switch 7 , and the pressure relief pipeline 5 is provided with a normally open solenoid valve 8 . The top of the hot water storage tank 1 is provided with a raised bulge 9, and the upper end of the hot water outlet pipe 3 extends into the raised bulge 9. The normally closed solenoid valve 4 is connected in parallel with the normally open solenoid valve 8 and then connected in series with the pressure switch 7 and the power supply 10 in turn. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com