Multi-stage retractile pneumatic hydraulic ejection device

An ejection device, pneumatic-hydraulic technology, applied in the direction of fluid pressure actuation device, launching/dragging transmission device, servo motor, etc., can solve the problems of unguaranteed ejection speed, small ejection stroke, low ejection efficiency, etc., and achieve higher ejection speed And ejection efficiency, the effect of improving ejection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

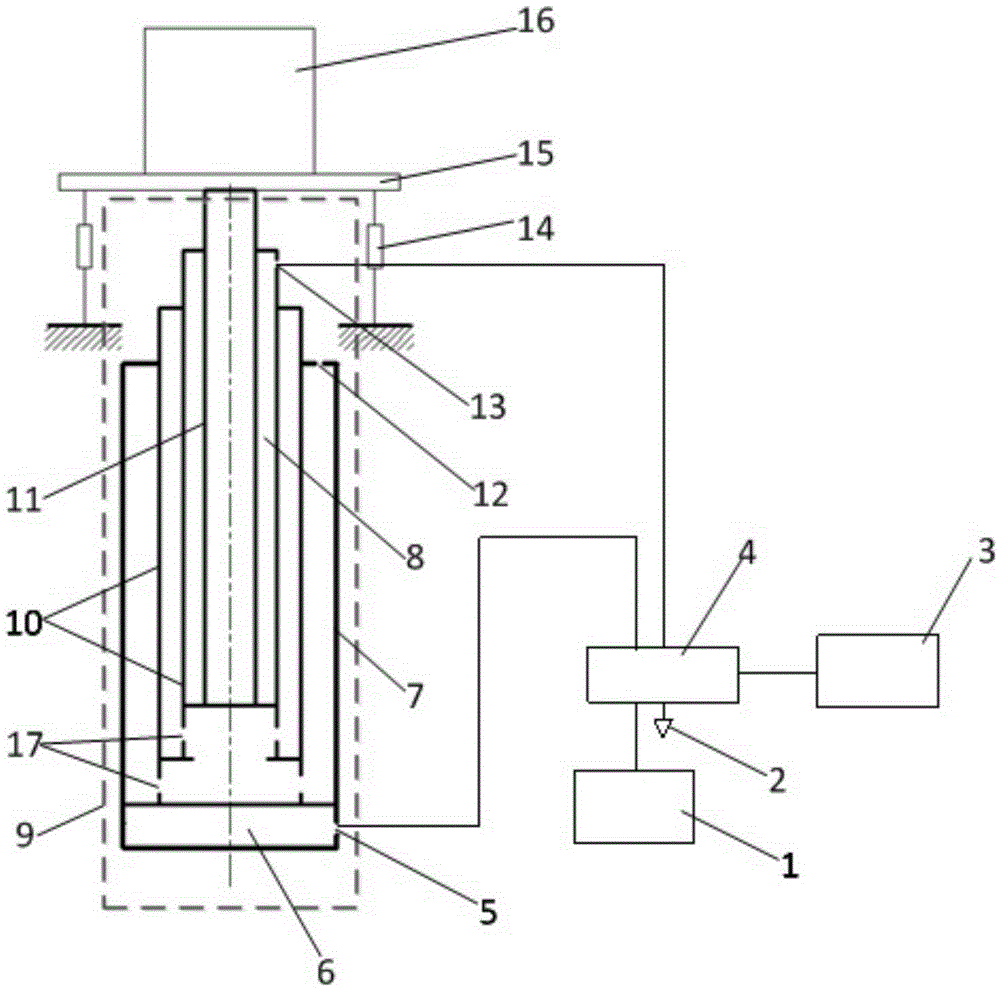

[0018] combine figure 1 :

[0019] A multi-stage retractable pneumatic-hydraulic ejection device, including a high-pressure air source 1, a controller 3, a pneumatic valve 4, a two-way gas-liquid mixing multi-stage cylinder 9, a pretensioning device 14, a bracket 15 and a load 16; wherein, The main cylinder body 7 of the two-way gas-liquid mixing multistage cylinder 9 is provided with a multistage sleeve type piston cylinder 10, and there is a cavity between the outer sleeve of the multistage sleeve type piston cylinder 10 and the inner wall of the main cylinder body 7. Filled with oil, the bottom of the multi-stage sleeve piston cylinder 10 is in sliding and sealing fit with the main cylinder body 7, and the open end of the main cylinder body 7 is in sliding and sealing fit with the multi-stage sleeve type piston cylinder 10, the multi-stage sleeve type The main gas chamber 6 is between the bottom of the piston cylinder 10 and the bottom of the main cylinder body 7. The mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com