A rocket-based combined cycle engine variable structure combustion chamber

A combustion chamber and engine technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of variable structure scheme and design without combustion chamber, achieve normal and efficient work, improve thrust and specific impulse performance, Effects of wide operating Mach number range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

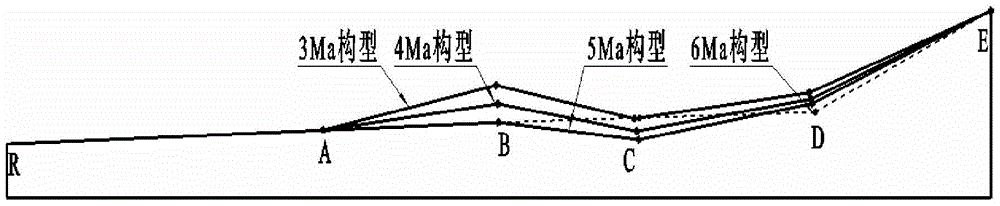

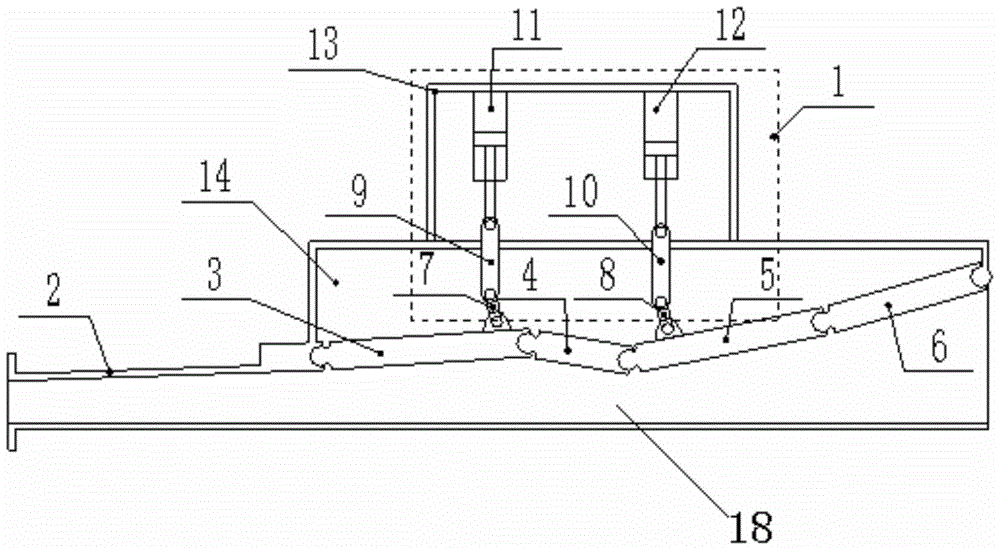

[0024] This embodiment is a variable structure combustion chamber of a rocket-based combined cycle engine.

[0025] refer to figure 1 , figure 2 , image 3 The variable structure combustion chamber of the rocket-based combined cycle engine is composed of a drive system 1, a back pressure chamber 14, and a combustion chamber 18. The drive system 1 is installed on the upper part of the back pressure chamber 14, and the back pressure chamber 14 is fixed on the variable section of the combustion chamber. , and form an integral structure with the combustion chamber 18; it can prevent the leakage of high-temperature gas in the combustion chamber.

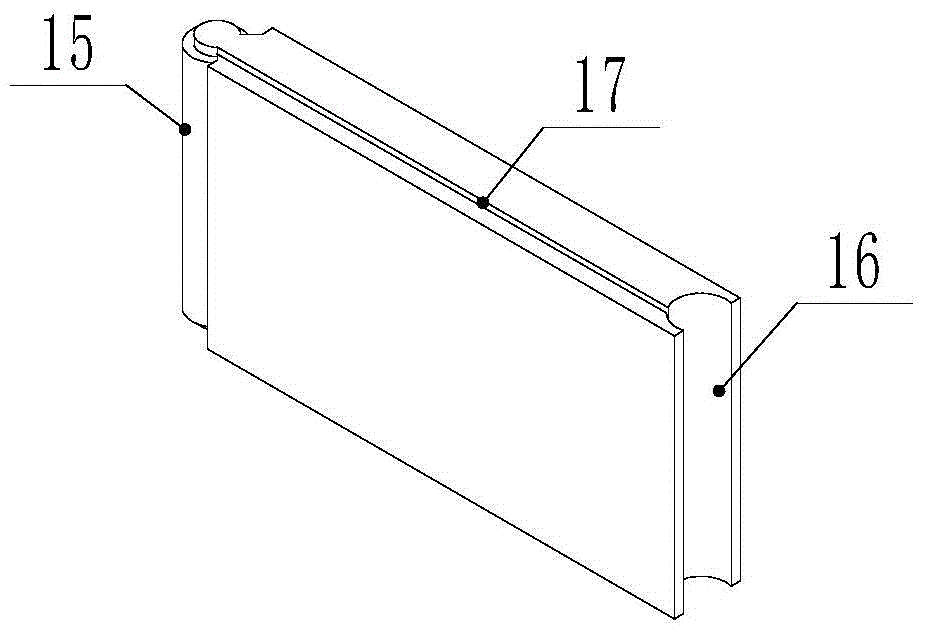

[0026] The combustion chamber 18 includes a combustion chamber fixed section 2, a first variable section 3, a second variable section 4, a third variable section 5, a fourth variable section 6, a ball joint convex surface 15, a ball joint concave surface 16, Axial sealing groove 17, the fixed section 2 of the combustion chamber is seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com