Wheel storing device of amphibious vehicles

A retractable device and amphibious vehicle technology, applied in amphibious vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of high shock absorber quality, harsh stress environment of shock absorber, and inconvenient shape design, etc., to achieve The effect of convenient vehicle layout, easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

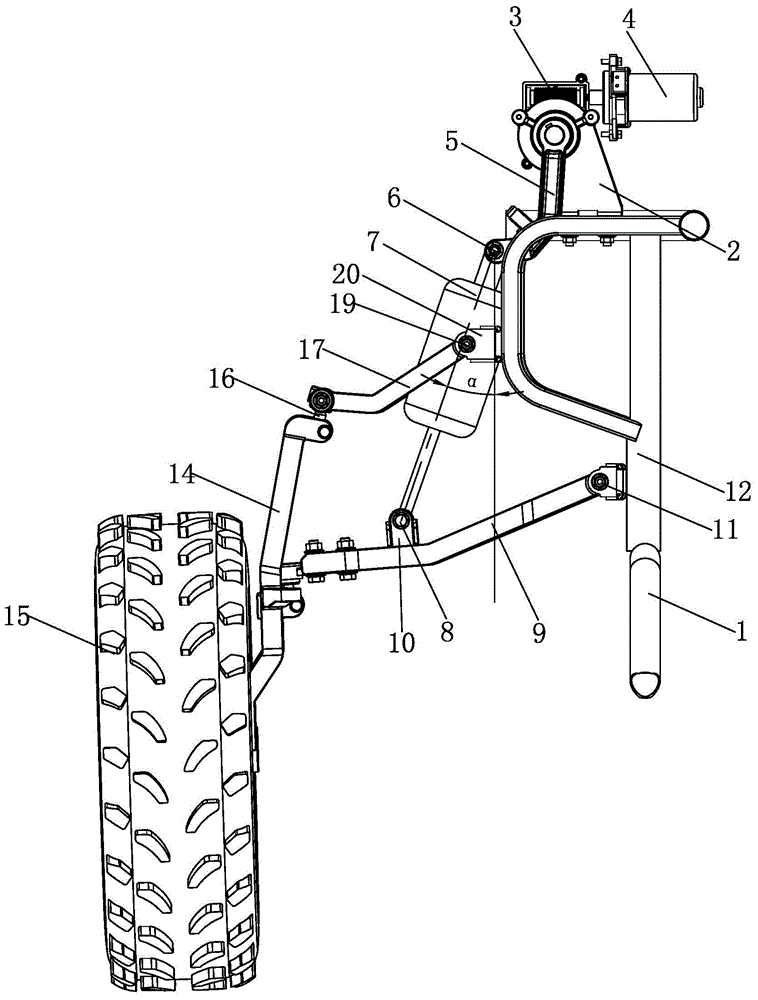

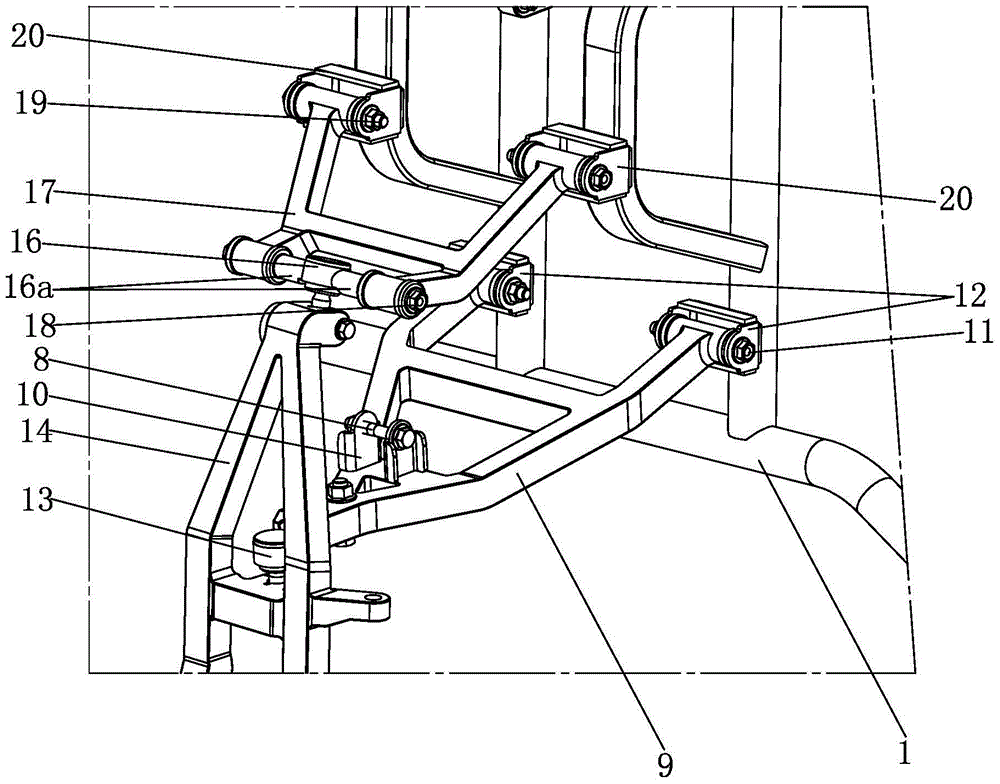

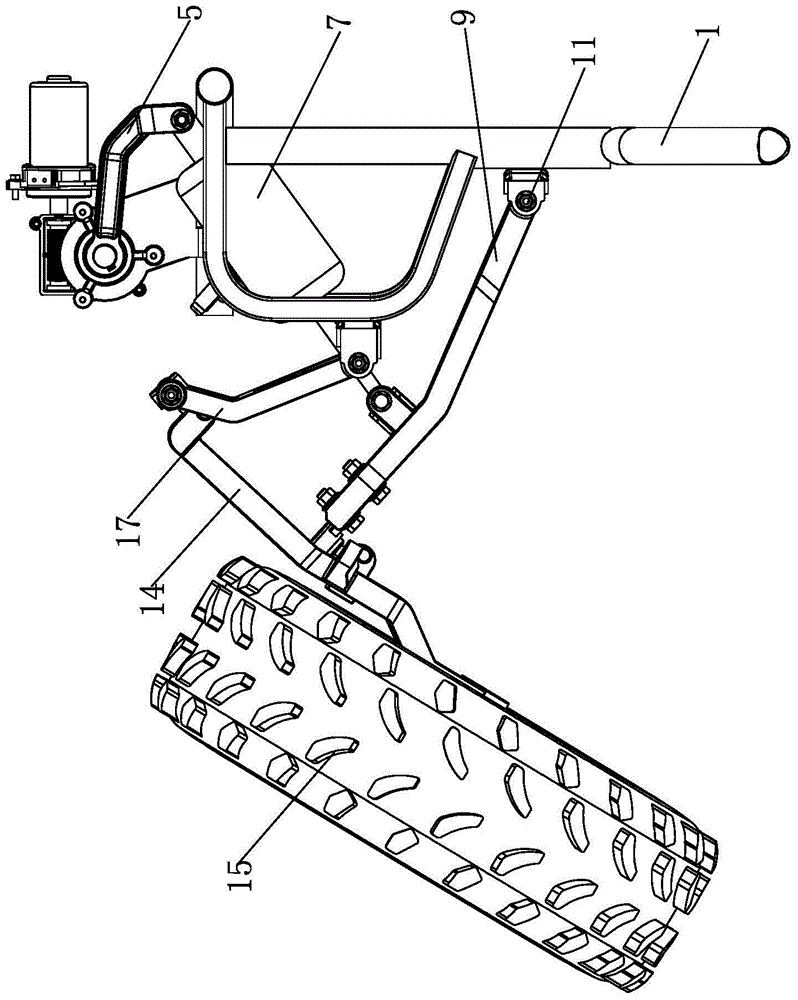

[0020] Such as figure 1 , 2 And shown in 3, a kind of amphibious vehicle wheel retractable device, mainly by vehicle frame assembly 1, rocker support 2, speed reducer 3, motor 4, rocker 5, the first pin shaft 6, shock absorber 7, the first Second pin shaft 8, lower cross arm 9, first lug 10, third pin shaft 11, second lug 12, lower ball bearing 13, horn 14, wheel assembly 15, upper ball bearing 16, upper cross An arm 17, a locking screw 18, a fourth pin shaft 19 and a third lug 20 constitute. Wherein, the frame assembly 1 is a welded assembly, and an outsourced rocker support 2 and a speed reducer 3 are fixedly installed on the top of the frame assembly 1, and the rocker support 2 is fixed to the frame assembly 1 by two screws. Wherein, the input end of the reducer 3 is coaxially connected with the output shaft of the motor 4, and the output end of the red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com