A kind of normal temperature short process reverse flotation method for hematite

A technology of reverse flotation and hematite, applied in flotation, solid separation, etc., can solve the problems of high bromination price, complicated process, high consumption, etc., achieve shortened process flow, simple and convenient production, and eliminate micelles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

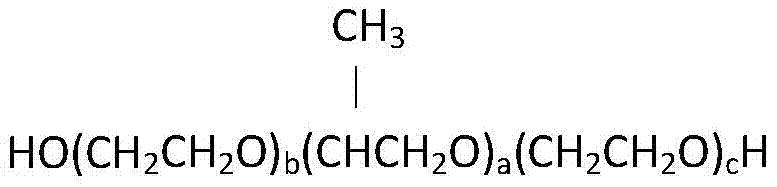

[0029] The chemical components of the red collector are: 5.0% sodium lignosulfonate; 90% acidified oil; 5% polyoxyethylene polyoxypropylene block polyether; the polyoxyethylene polyoxypropylene block The structural formula of polyether is:

[0030]

[0031] where a=15, b=8, c=12;

[0032] The acid value of the acidified oil is 150KOH mg / g, the saponification value is 200KOH mg / g; the iodine value is 120I 2 g / 100g;

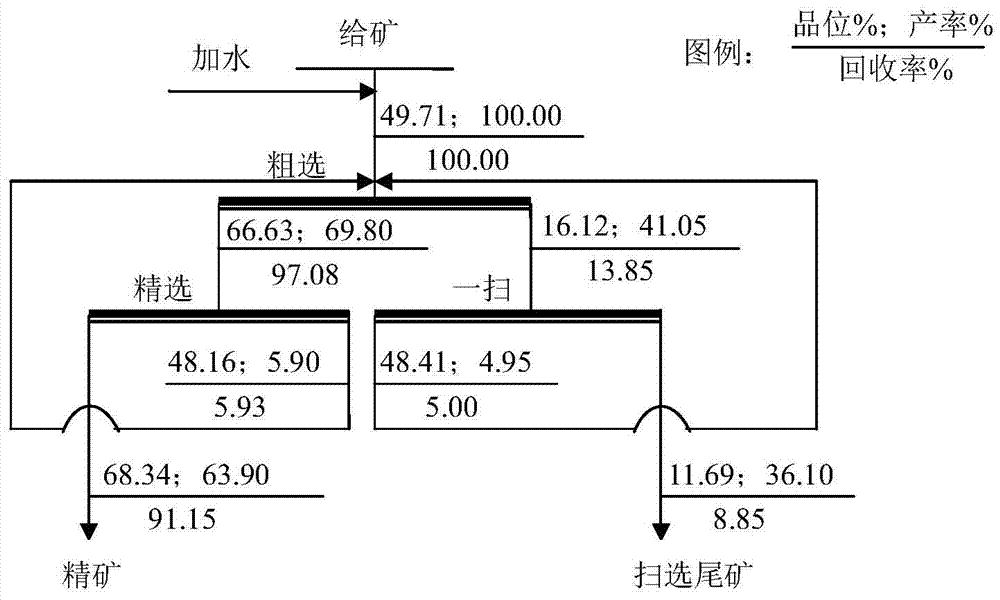

[0033] Use process such as figure 1 Shown:

[0034] The mixed magnetic concentrate taken from a flotation plant in Anshan with an iron grade of 47.91% is used as the ore feed. The temperature of the slurry is controlled at 22°C. The dosage of the regulator sodium hydroxide is 700g per ton of feed ore during reverse flotation roughing. , the amount of inhibitor starch is 700g per ton of ore feed, the amount of activator calcium oxide is 560g per ton of ore feed, and the amount of collector is 400g per ton of ore feed; carry out reverse flotation roughing, tim...

Embodiment 2

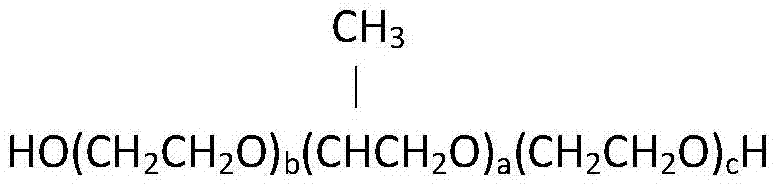

[0038] The chemical composition of the collector is as follows: acidified oil 80%; polyoxyethylene polyoxypropylene block polyether 20%; polyoxyethylene polyoxypropylene block polyether in the structural formula a=17, b=12, c=8;

[0039] The acid value of the acidified oil is 110KOH mg / g, the saponification value is 160KOH mg / g; the iodine value is 90I 2 g / 100g;

[0040] Method is with embodiment 1, and difference is:

[0041] (1) The mixed magnetic concentrate with a grade of 47.91 is made into pulp, and the temperature of the pulp is controlled at 24°C. The amount of sodium hydroxide is 750g per ton of ore, the amount of starch is 800g per ton of ore, and the amount of calcium oxide is Add 570g per ton of ore, and add 400g of collector per ton of ore, and the roughing and reverse flotation time is 3.5min;

[0042] (2) The beneficiation control is carried out at 24°C, the dosage of the regulator sodium hydroxide is 95g per ton of ore feed, the amount of collector is 150g p...

Embodiment 3

[0045] The chemical composition of the collector is as follows: sodium lignosulfonate 18%; acidified oil 75%; polyoxyethylene polyoxypropylene block polyether 7%; polyoxyethylene polyoxypropylene block polyether in the structural formula a=18, b=10, c=11;

[0046] The acid value of the acidified oil is 130KOH mg / g, the saponification value is 180KOH mg / g; the iodine value is 100I 2 g / 100g;

[0047] Method is with embodiment 1, and difference is:

[0048] (1) Control the temperature of the pulp at 25°C, add 750g of sodium hydroxide per ton of ore feed, 750g of starch per ton of ore feed, and 565g of calcium oxide per ton of ore feed, collector The dosage is to add 405g per ton to the ore, and carry out reverse flotation roughing, and the time is 4min;

[0049] (2) Under the condition of 25°C, the dosage of regulator sodium hydroxide is 100g per ton of feed ore, the amount of collector is 160g per ton of feed ore, and the reverse flotation concentration time is 3min;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com