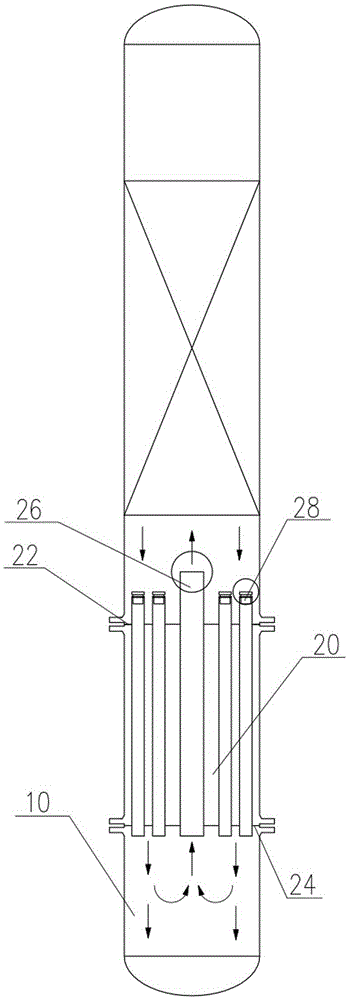

Built-in falling film-type reboiler rectification tower and rectification method thereof

A reboiler and rectification tower technology, which is applied to the built-in falling film reboiler rectification tower and its rectification field, can solve the problems of high investment and operation cost, unstable operation, poor film-forming effect, etc. Equipment investment and operating costs, and the effect of increasing operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The 2t / h rich amine liquid to be separated enters the rectification tower with built-in falling film reboiler. Due to rectification, the material containing most of the heavy components descends, and is evenly scattered and collected into the upper tube sheet through the last layer of packing. The operating pressure is 0.1MPa (G), and the tower diameter is DN500.

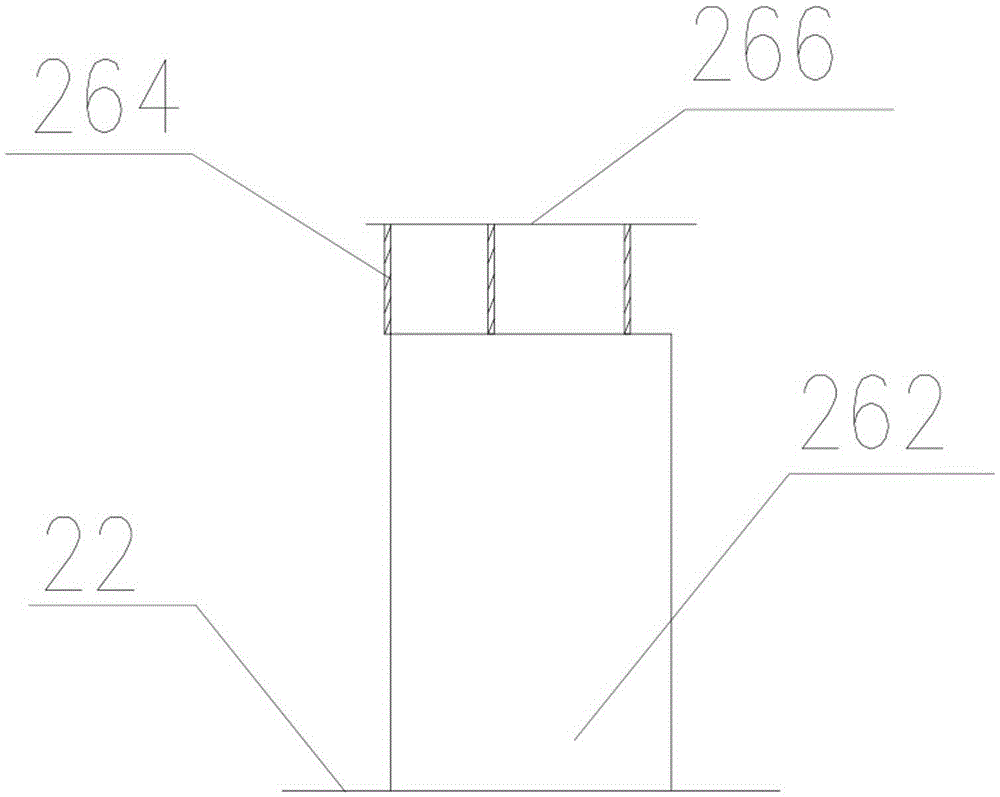

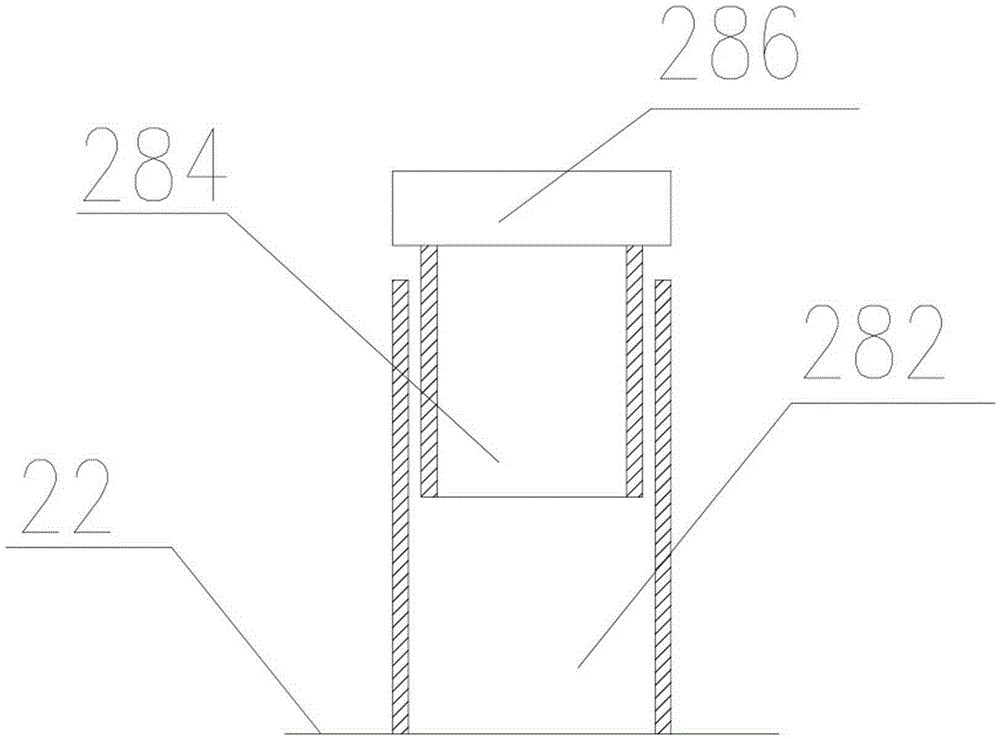

[0073] The liquid layer on the upper tube plate flows into the heat exchange tube from the gap between the cap and the serrated opening, and under the action of the draft tube, a uniform and stable downward flowing film is formed between the outer wall of the draft tube and the inner wall of the heat exchange tube. In the liquid layer, the depth-to-width ratio of the zigzag opening is 1.5, the heat exchange tube is DN32 heat exchange tube with a length of 2.5m, and the diversion tube is DN25 diversion tube.

[0074] The film-like liquid layer is continuously vaporized under the action of the heating medium ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com