Energy guiding chain

A technology of energy guide chains and components, applied in the field of energy guide chains, which can solve problems such as insufficient realization and difficulty, and achieve the effect of easy insertion and replacement, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

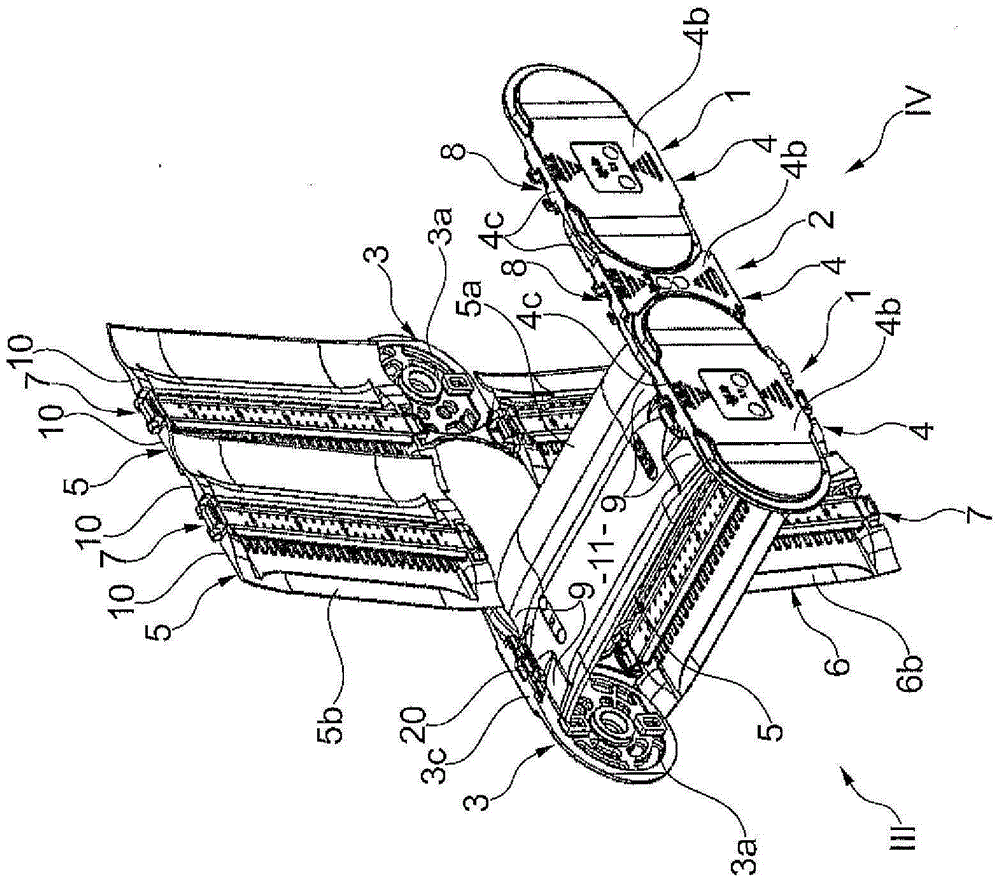

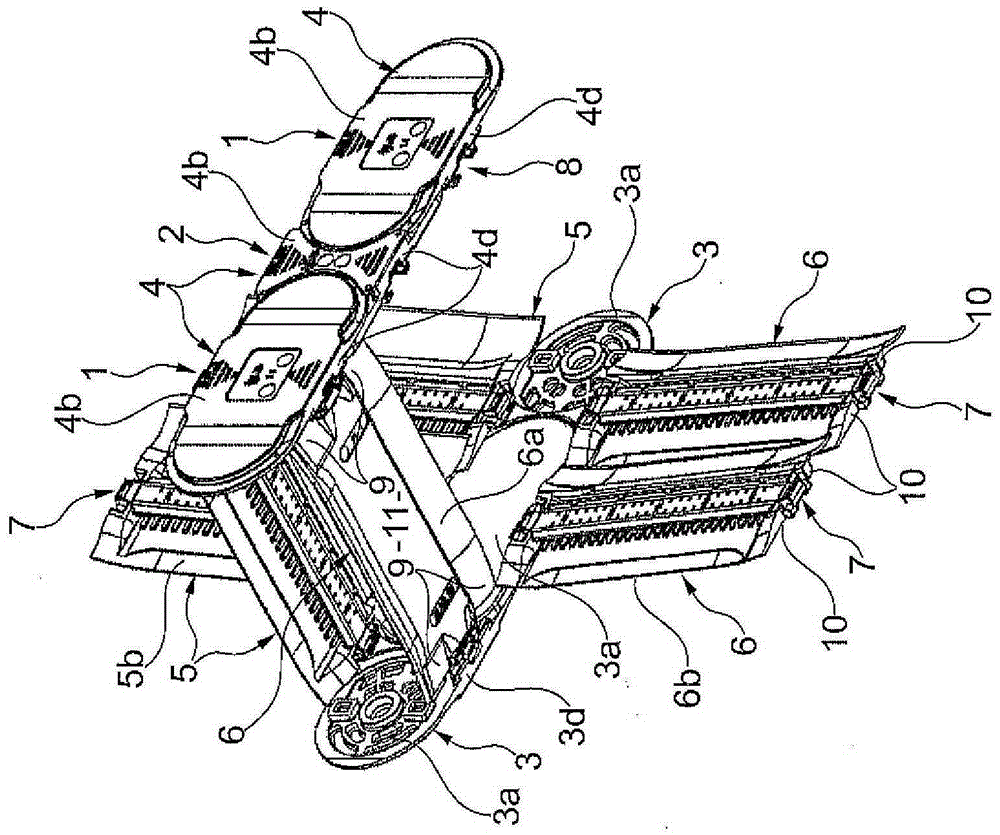

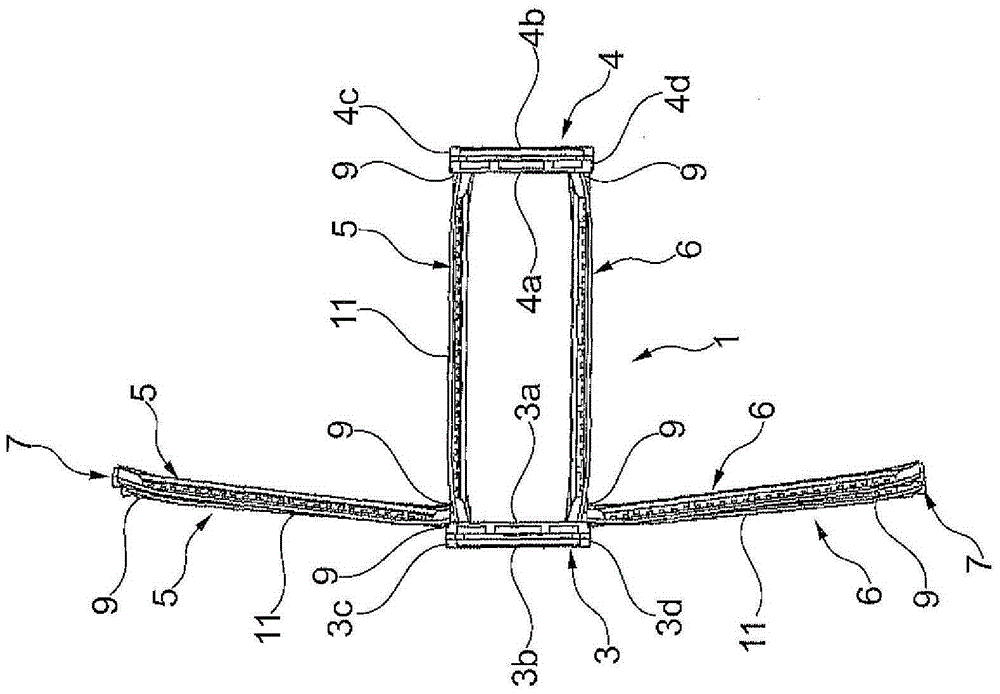

[0045] exist figure 1 The part of the energy guide chain / energy chain shown in is composed of three chain links, wherein the outer chain link 1 comprises opposite side straps 3 which overlap the side straps 4 of the inner chain link 2 on the outside. The side straps 3 and 4 form opposing strap bundles transversely to their longitudinal direction, which continue over the entire length of the energy conducting chain.

[0046] The energy guide chain / energy chain comprises a plurality of chain links 1, 2 which are pivotable relative to each other within a certain pivot angle and which extend from a first connection point (not shown in the figure) to A second connection point (not shown in the figure) movable relative to the first connection point.

[0047] as from figure 1 and 2 It can be seen that each side strap 3, 4 comprises an inner side 3a, 4a facing the inside of the chain, an outer side 3b, 4b facing outwards, and a side strap perpendicular to said inner side and said o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com