Upper sealing head structure of fiber ultrafiltration membrane

A technology of ultrafiltration membrane and head, which is applied in the field of hollow fiber ultrafiltration membrane modules, which can solve the problems of time-consuming installation and disassembly, many live joint parts, and water leakage at the joints, and achieve fast installation and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited to the embodiments.

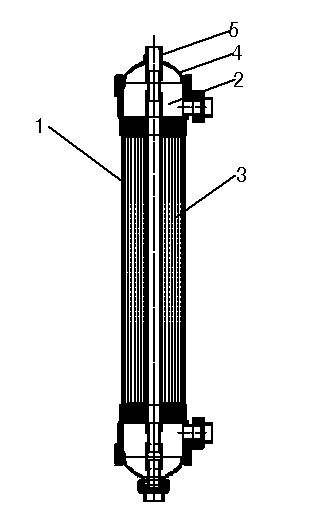

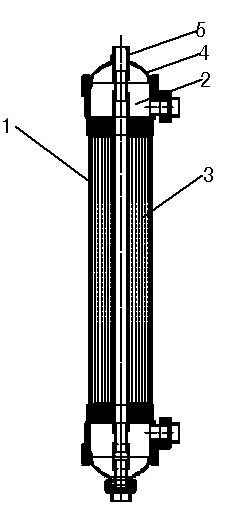

[0008] as attached figure 1 As shown, the present invention provides a head structure on a fiber ultrafiltration membrane, including a pressure-bearing shell, a head, a head connection end and a fiber ultrafiltration membrane, and the head connection end is provided with a water inlet for connecting with an external pipeline , the water inlet is a quick-connect joint, and the quick-connect joint and the connecting end of the head are formed integrally through a mold, and then are sealed and connected to the external pipeline by an adhesive. Compared with the existing technology, the water inlet is designed as a quick-connect interface, which is directly bonded with the external pipe with glue. Compared with the previous threaded connection, the sealing is better and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com