Novel overall carbon brush holder

A carbon brush holder and overall technology, which is applied in the field of new overall carbon brush holders, can solve problems such as easy failure, inconvenient maintenance and repair, and complex structure, and achieve the effects of low failure in use, easy installation, maintenance and replacement, and a stable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

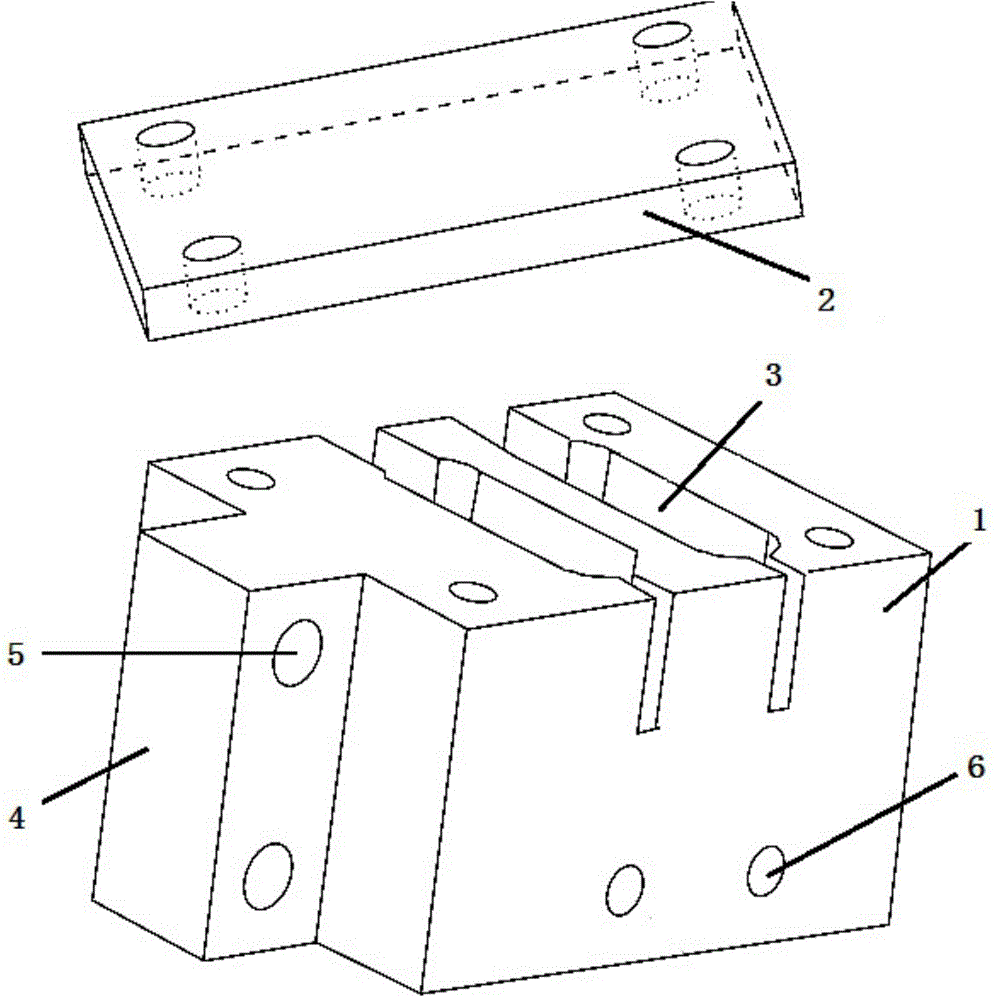

[0017] Such as figure 1 As shown, a new type of integral carbon brush holder includes a carbon brush holder main body 1 and an upper cover 2 made of insulating materials, which can be machined step by step or molded at one time, such as: injection molding, compression molding, etc. The upper cover 2 Set on the upper end surface of the carbon brush holder main body 1, the upper part of the carbon brush holder main body 1 is provided with a carbon brush fixing cavity 3, and the carbon brush is installed in the cavity between the carbon brush fixing cavity 3 and the upper cover 2, and on the carbon brush holder main body The fixed end 4 of 1 is drilled with a fixing screw hole 5, which can be rigidly fixed on the motor or other equipment directly with screws. On the side of the main body 1 of the carbon brush holder, there is a wire connection fixing screw hole 6, which can be connected to the fixing screw through the wire. The carbon brush is externally connected to the power li...

Embodiment 2

[0019] Such as figure 1 The difference between the shown structure and Example 1 is that the upper cover 2 is removed, the main body of the carbon brush holder is made of nylon material, and the mold is one-time injection molded. The carbon brush is inserted and installed from the front end in the air, and fixed in the wire connection fixing screw hole.

Embodiment 3

[0021] Such as figure 1 The middle structure is different from Example 2 in that it is the same except that the injection molding material is polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com