Heatproof oil-resistant cable

An oil-resistant and heat-resistant technology, which is applied in the field of heat-resistant and oil-resistant cables, can solve the problems that the oil resistance and heat resistance of cables cannot meet the requirements of modern society, poor adhesion, and EPDM rubber is not oil-resistant, etc., to improve the resistance Effects of ozone aging resistance, improvement of adhesion and oil resistance, and improvement of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

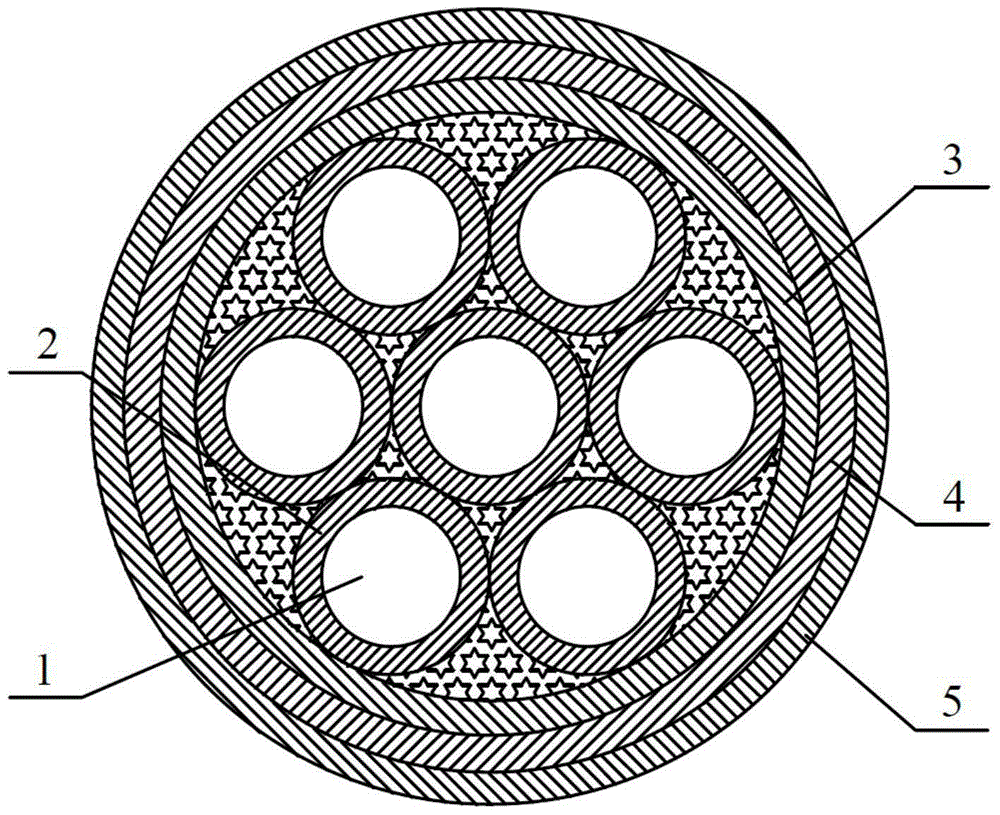

[0025] figure 1 It is a schematic diagram of the structure of the heat-resistant and oil-resistant cable of the present invention, refer to figure 1 , The heat and oil resistant cable of the present invention includes a cable core. The cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and an inner sheath layer 3 is provided with a steel belt armor layer 4, and is provided with an outer sheath layer 5 outside the steel belt armor layer 4. The outer sheath layer 5 is made of heat-resistant and oil-resistant modified EPDM rubber material, wherein the heat-resistant The raw materials of oil-resistant modified EPDM rubber material include the following components by weight: 50 parts EPDM rubber, 50 parts nitrile rubber, 12 parts carbon nanotubes, 20 parts nano alumina, and modified attapulgite 8 parts, 2 parts stearic acid, 0.3 parts z...

Example Embodiment

[0027] Example 2

[0028] figure 1 It is a schematic diagram of the structure of the heat-resistant and oil-resistant cable of the present invention, refer to figure 1 , The heat and oil resistant cable of the present invention includes a cable core. The cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and an inner sheath layer 3 is provided with a steel belt armor layer 4, and is provided with an outer sheath layer 5 outside the steel belt armor layer 4. The outer sheath layer 5 is made of heat-resistant and oil-resistant modified EPDM rubber material, wherein the heat-resistant The raw materials of oil-resistant modified EPDM rubber material include the following components by weight: 70 parts EPDM rubber, 30 parts nitrile rubber, 30 parts carbon nanotubes, 8 parts nano alumina, and modified attapulgite 20 parts, stearic acid 0.5 part, zinc oxide...

Example Embodiment

[0030] Example 3

[0031] figure 1 It is a schematic diagram of the structure of the heat-resistant and oil-resistant cable of the present invention, refer to figure 1 , The heat and oil resistant cable of the present invention includes a cable core. The cable core includes a conductor 1 located in the middle and an insulating layer 2 covering the outside of the conductor; an inner sheath layer 3 is provided outside the cable core, and an inner sheath layer 3 is provided with a steel belt armor layer 4, and is provided with an outer sheath layer 5 outside the steel belt armor layer 4. The outer sheath layer 5 is made of heat-resistant and oil-resistant modified EPDM rubber material, wherein the heat-resistant The raw materials of oil-resistant modified EPDM rubber material include the following components by weight: 60 parts EPDM rubber, 43 parts nitrile rubber, 17 parts carbon nanotubes, 15 parts nano alumina, and modified attapulgite 12 parts, 1.5 parts of stearic acid, 0.6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com