A fan coil temperature control panel with cleaning mode

A temperature control panel and cleaning mode technology, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., can solve problems such as power waste, complexity, and discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

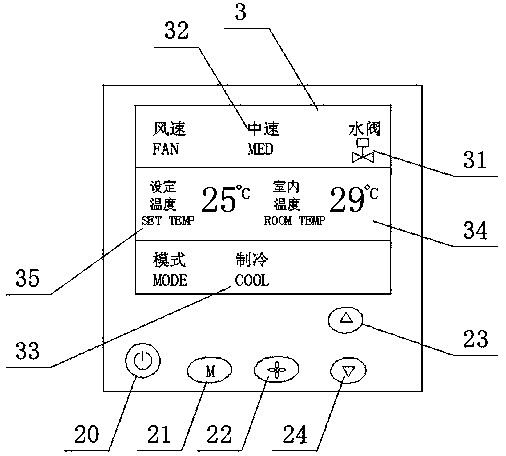

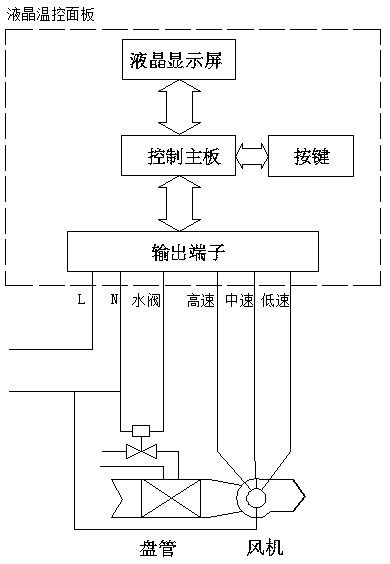

[0031] refer to figure 1 and figure 2 , the fan coil temperature control panel with cleaning mode provided in this embodiment has the same hardware as the existing temperature control panel, including switch button 20, mode button 21, wind speed button 22, temperature rise button 23, temperature drop button 24, liquid crystal display Screen 3, control board, output terminal. The liquid crystal display 3 and buttons are all arranged on the upper part of the temperature control panel, and the output board is at the bottom of the temperature control panel, and are connected with the fan and electric water valve outside the temperature control panel by wires; the liquid crystal display 3, buttons, and output terminals are all connected to the temperature control panel control board connection inside the control panel.

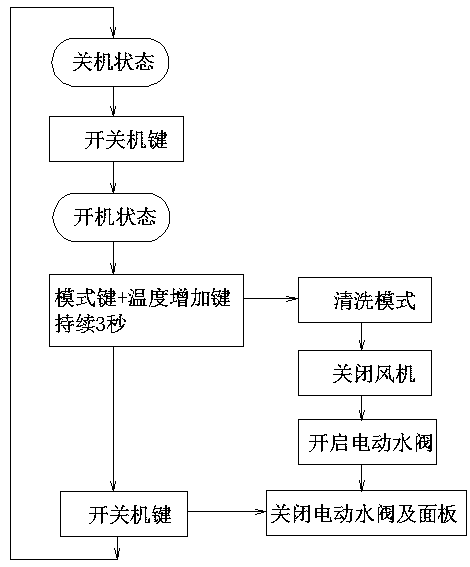

[0032] refer to image 3 In addition to the above existing operating modes of the existing temperature control panel, such as automatic, cooling, heating, dehu...

Embodiment 2

[0036] refer to figure 1 , Figure 4 , The difference from Embodiment 1 is that the program trigger of the cleaning mode can also be called out by any combination of two or three buttons on the temperature control panel. For example, by simultaneously pressing the mode key 24 and the heating button 23 and keeping it for 3 seconds, or pressing the mode key 21, the heating button 23 and the cooling button 24 simultaneously and keeping it for 3 seconds, the cleaning mode is called out. The 3 seconds can be appropriately shortened or extended.

Embodiment 3

[0038] The difference from Embodiment 1 is that the cleaning mode can also be turned on or off remotely with a computer through the network interface configured on the temperature control panel of the fan coil unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com