Auxiliary device of friction clutch

A friction clutch and auxiliary device technology, applied in the direction of clutches, non-mechanical drive clutches, mechanical equipment, etc., can solve the problems of car stalling and unsmooth driving, and achieve the effects of low power consumption, rapid separation and soft engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, patent of the present invention is described further.

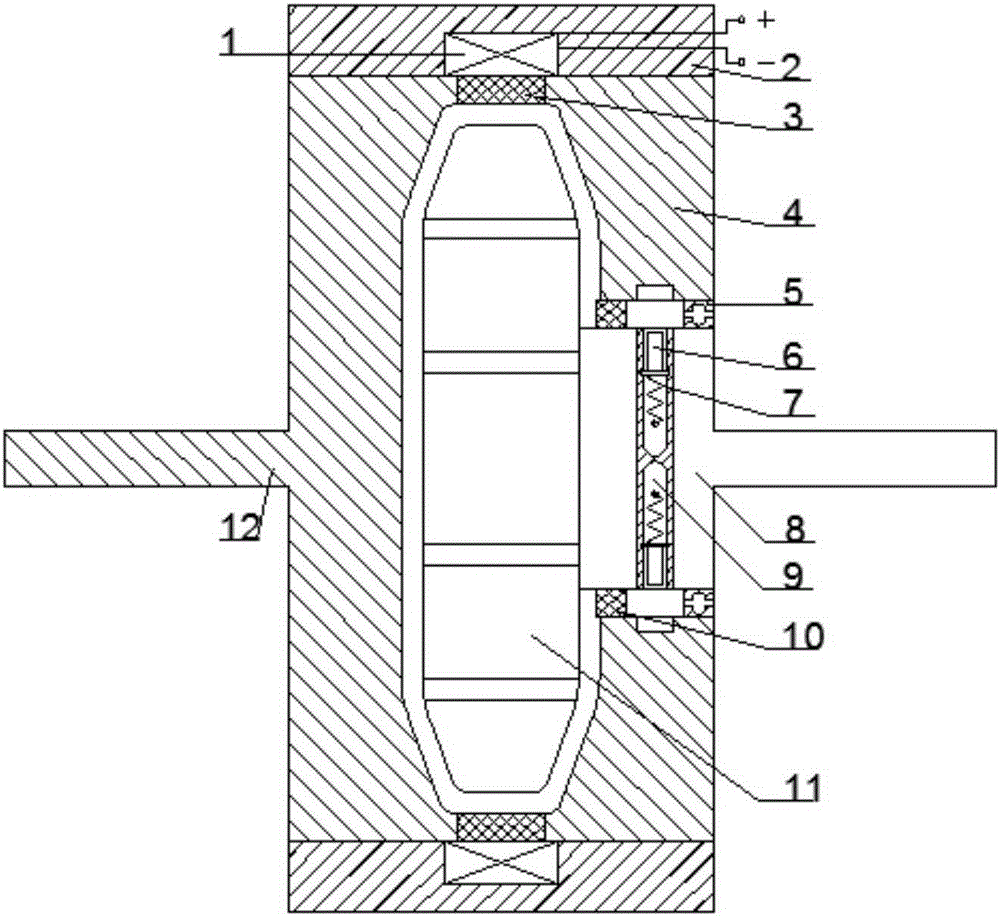

[0020] Refer to attached figure 1 The present invention includes an electromagnetic coil 1, an outer magnetic core 2, a non-magnetic seal 3, a cylinder body 4, a bearing 5, a slider 6, a return spring 7, an output shaft 8, an electromagnetic valve 9, a seal 10, and a driven disk 11. Input shaft 12.

[0021] In the present invention, the input shaft of the auxiliary device is the output shaft of the friction clutch, and the output shaft of the auxiliary device is used as the input shaft of the transmission; the working cylinder is filled with magnetorheological fluid; the electromagnetic coil surrounds the outside of the working cylinder and is controlled by the ECU. The magnitude of the electromagnetic coil current and the magnitude of the current generation determine the viscosity coefficient of the magneto-rheological fluid, so that the joint is softer, smoother an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com