Supporting method for superhigh sections of two ends of fully-mechanized mining face

A fully mechanized mining face and ultra-high section technology, applied to mining equipment, earthwork drilling, mine roof supports, etc., can solve the problems of high labor intensity, difficult safety management, high cost, etc., and achieve simple, labor-saving and convenient operation Fast-pass, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

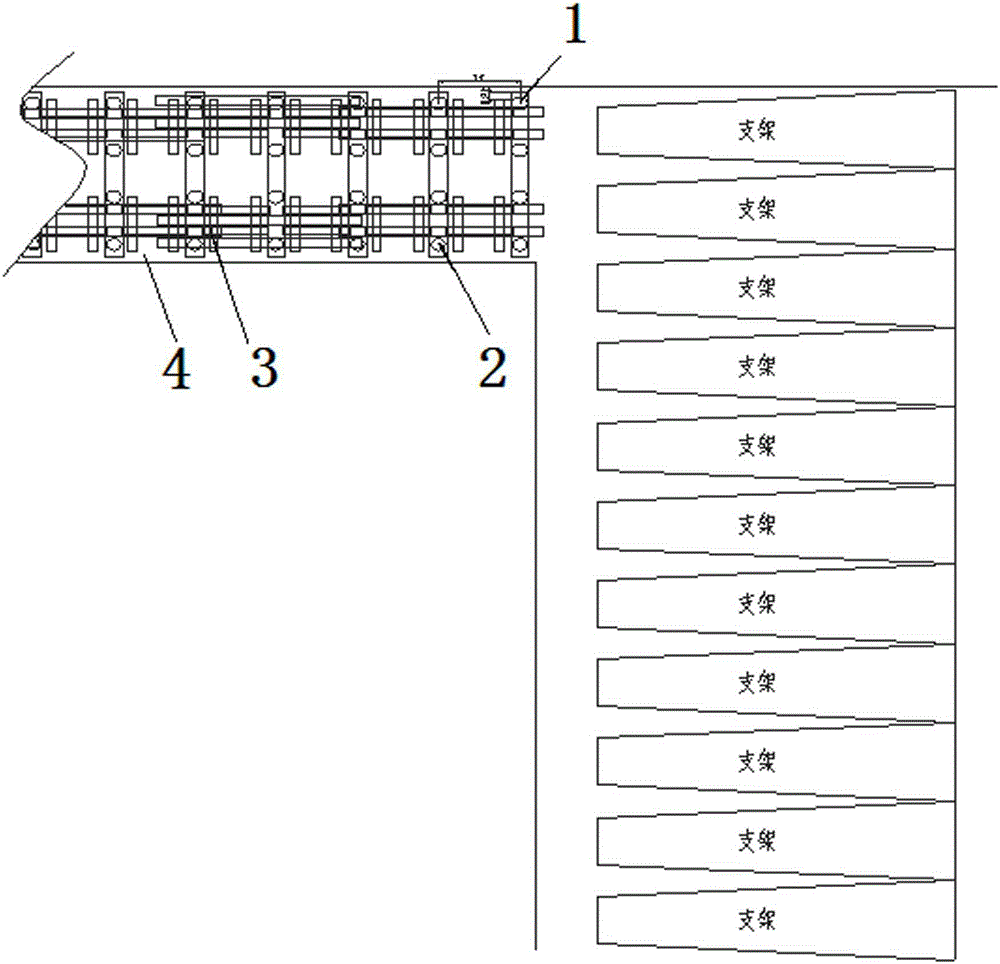

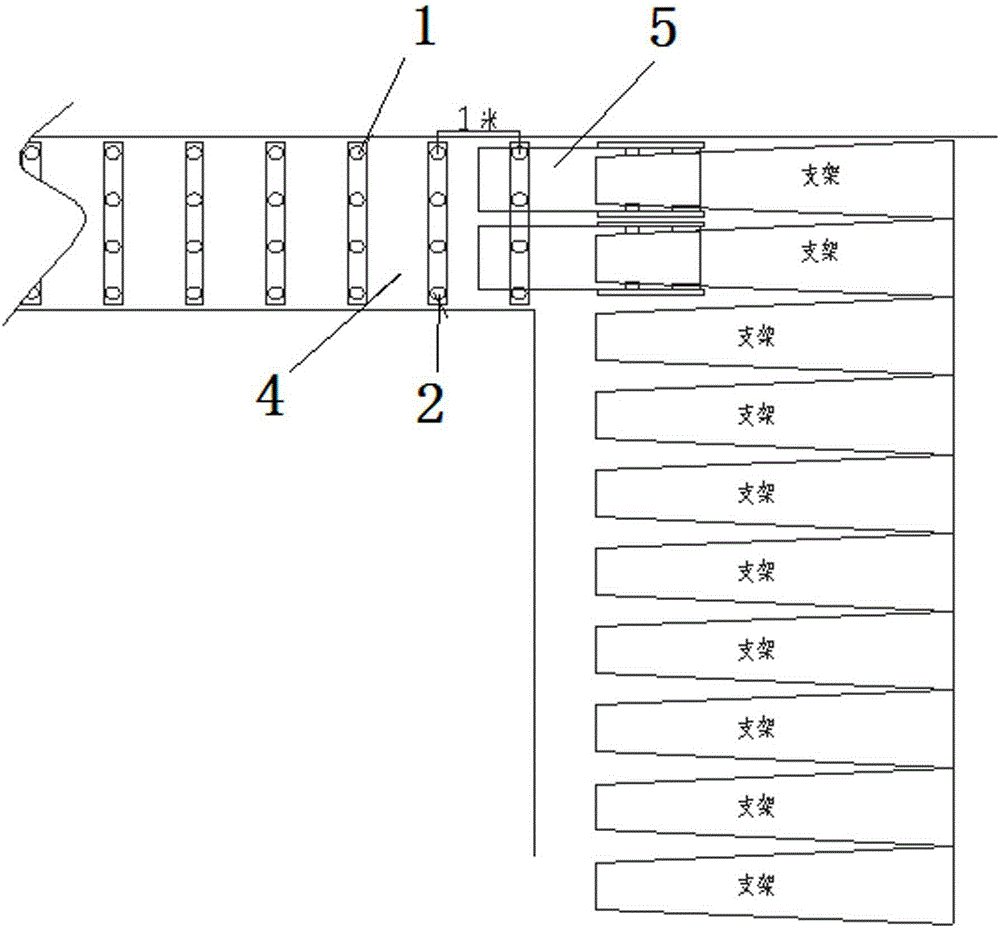

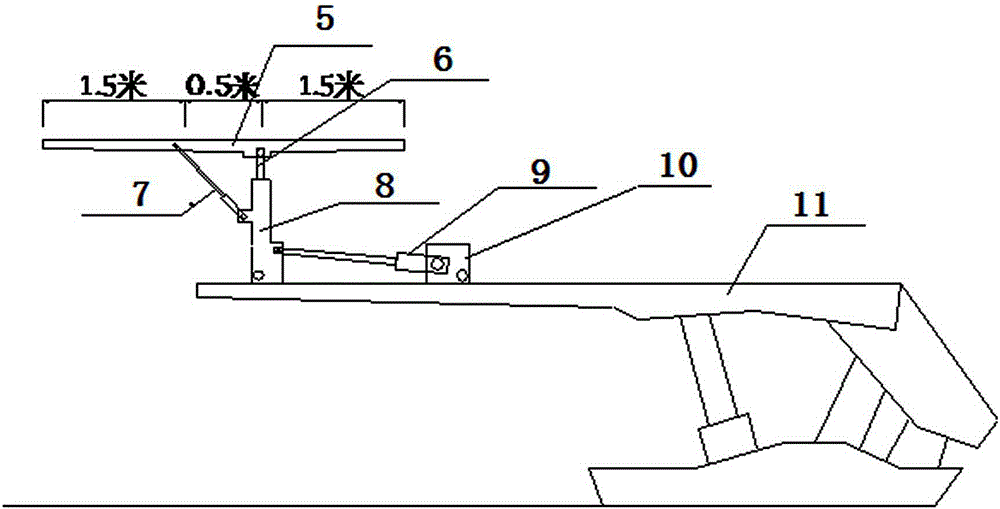

[0011] Such as figure 2 , 3 , 4, and 5 show a method for supporting the two ends of a fully mechanized mining face over the superelevation section. to the top of the hydraulic support, and connect the hydraulic support device to the control device near the handle of the support through the hydraulic pipeline. Lifting oil cylinder 6, top beam 5, overturning oil cylinder, supporting oil cylinder 7 are formed; Support base 10 is installed on the top plate of hydraulic support 11 first, then overturning oil cylinder 9 is installed on support base 10, and overturning beam 8 is also installed on hydraulic support 11 , the overturning cylinder 9 is connected to the overturning beam 8, the lifting cylinder 6 is installed above the overturning beam 8, the supporting cylinder 7 is installed on the side, and the supporting cylinder 7 and the lifting cylinder 6 support the top beam 5 together.

[0012] By starting the hydraulic source to control the lifting of the support of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com