A crawler type segment secondary lining equipment

A secondary lining and crawler-type technology, applied in shaft lining, tunnel lining, mining equipment, etc., can solve the problems of easily damaged tunnels, weak structural strength, tunnel damage, etc., achieve uniform force, improve construction efficiency, increase The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

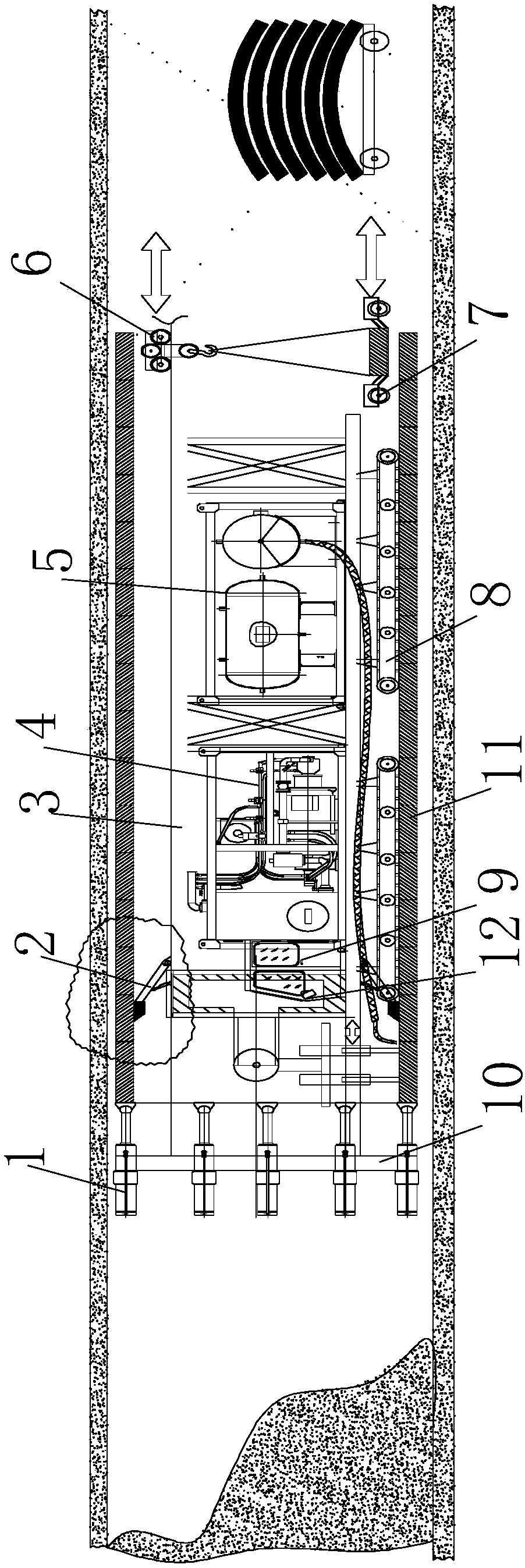

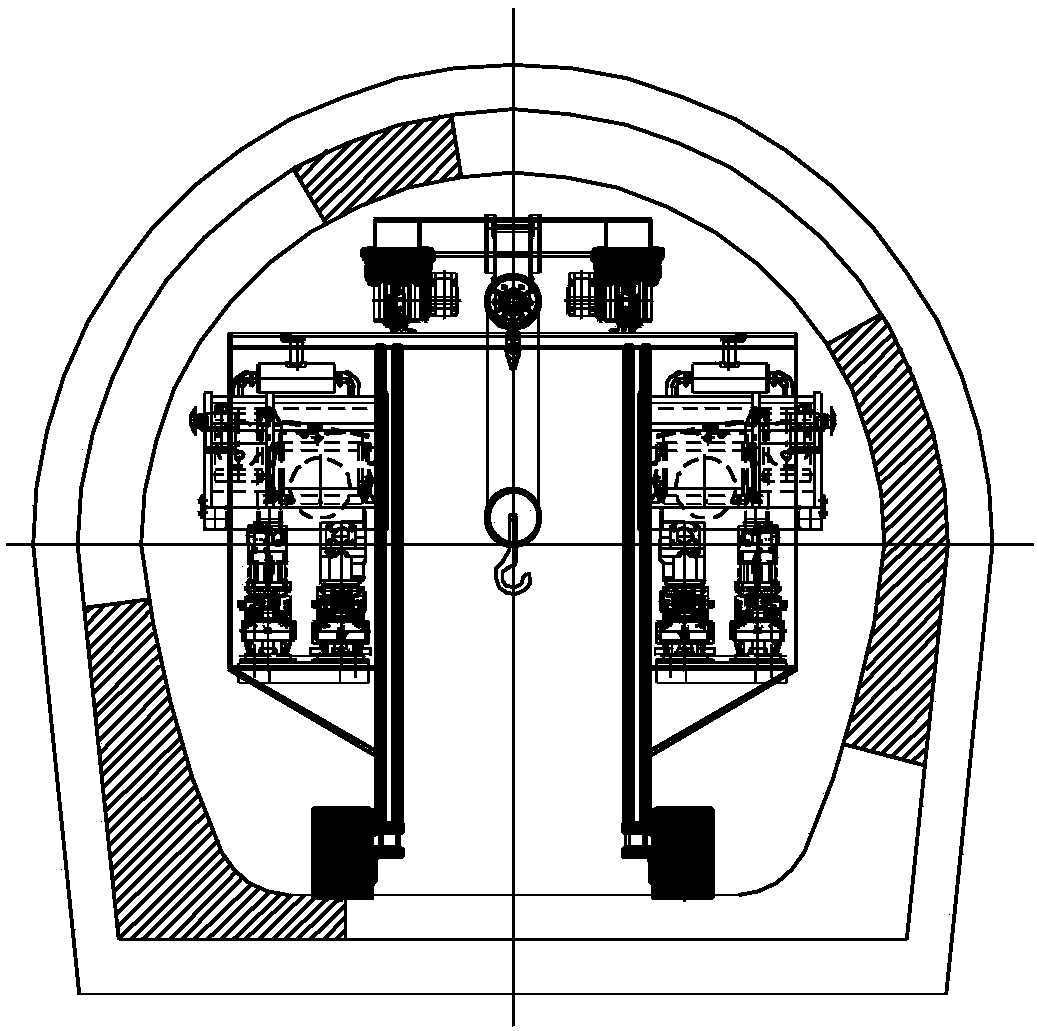

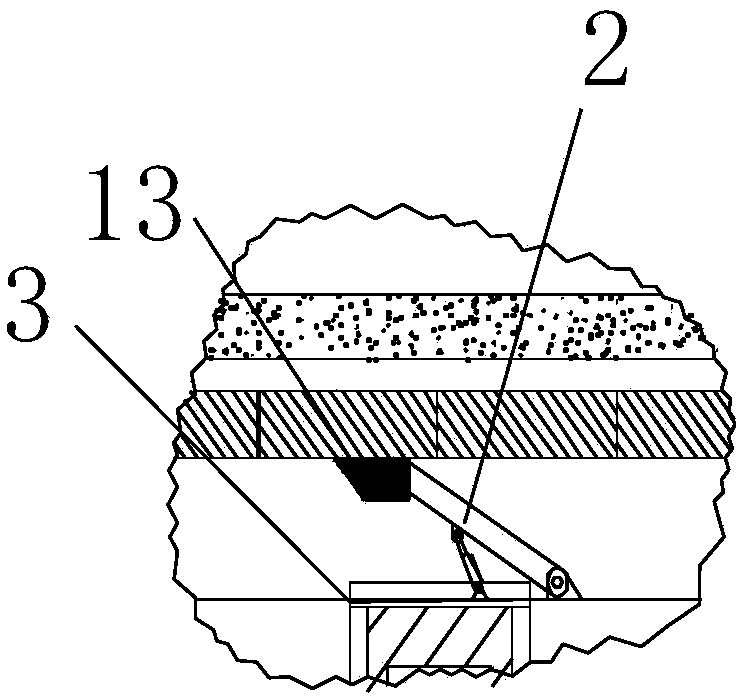

[0017] Such as Figure 1-3 As shown, this embodiment provides a crawler-type tube segment secondary lining equipment, which includes a main body frame 3, and a flat-bottomed horseshoe-shaped steel support frame 10 similar to the section of the tube piece is provided at the front end of the main body frame 3. A plurality of squeezing oil cylinders 1 are uniformly distributed on the frame 10, and the squeezing oil cylinder 1 corresponds to the lining tube piece 11. A rotary tube piece assembling machine 12 is provided at the head of the main frame 3, and the main frame A crawler-type walking chassis 8 is arranged below the main frame 3. A plurality of lockers are provided behind the tube piece assembly machine on the main frame 3, and the lockers are used to lock the entire equipment when the tube piece is assembled. Unlock when the whole device is walking.

[0018] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com