Single-wheel groove milling equipment and construction method thereof for underground diaphragm wall grooving

An underground diaphragm wall and single-wheel technology, applied in sheet pile walls, foundation structure engineering, earth movers/shovels, etc., can solve problems such as poor quality of groove formation, long construction period, and inefficiency of impact drilling, etc., and achieve The effect of low design and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

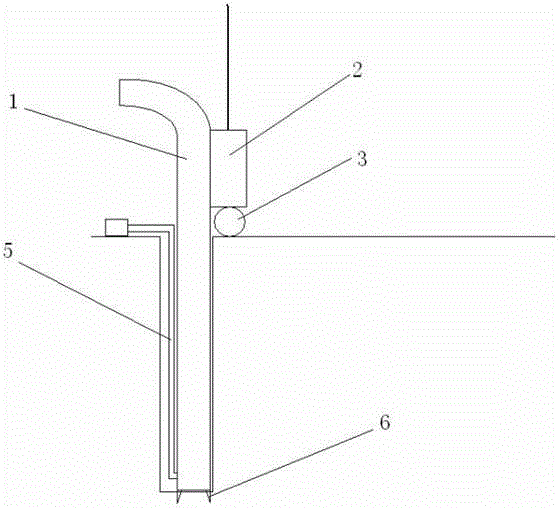

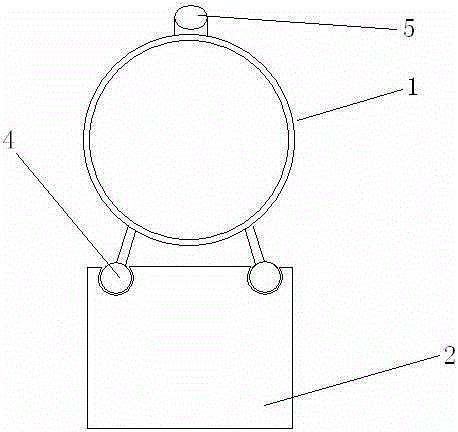

[0029] As shown in the figure, a single-wheel groove milling equipment for forming underground continuous wall grooves according to the present invention includes a groove milling device and a slag discharge device;

[0030] The groove milling device includes a slag spray pipe 1 vertically arranged in the underground borehole. The length of the slag spray pipe 1 is greater than the depth of the underground borehole. Yes, a single-wheel milling machine is provided on one side of the slag spraying pipe 1, and the single-wheel milling machine is located in the direction that needs to be milled. The single-wheel milling machine includes an upper frame 2 and a lower cutting wheel 3. The single-wheel The slot milling machine has all the necessary components and mechanisms that can be carried out on the general double-wheel slot milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com