Adjustable grain collection device in sunning ground

An adjustable, drying yard technology, applied in loading/unloading, transportation and packaging, conveying bulk materials, etc., can solve the problems of high grain damage rate, too late to collect grain, and poor grain harvesting efficiency, reducing labor intensity, The effect of low manufacturing cost and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

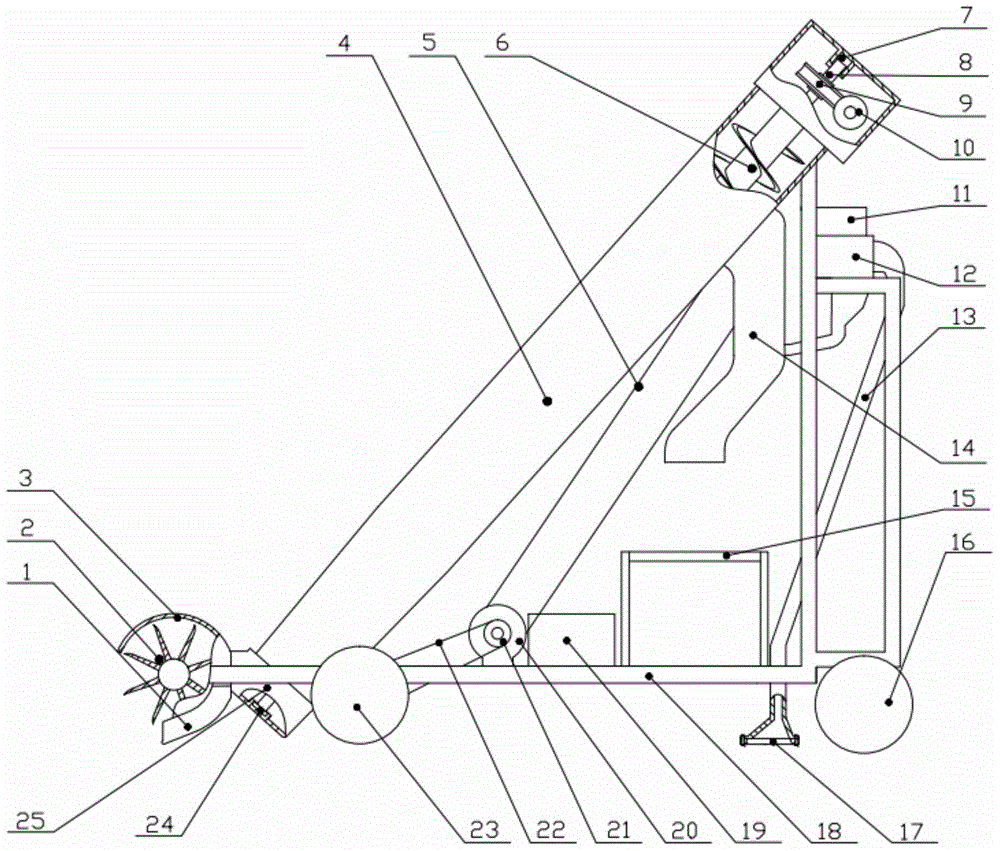

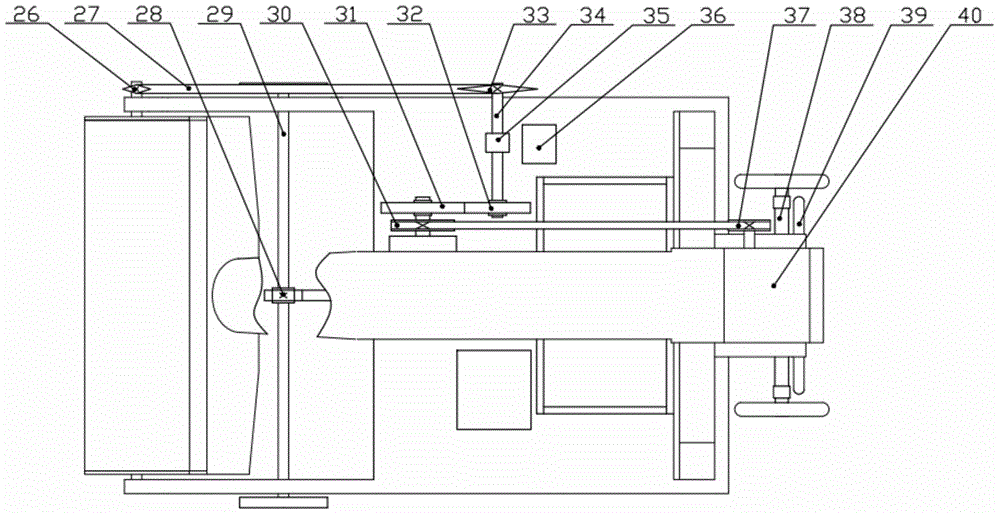

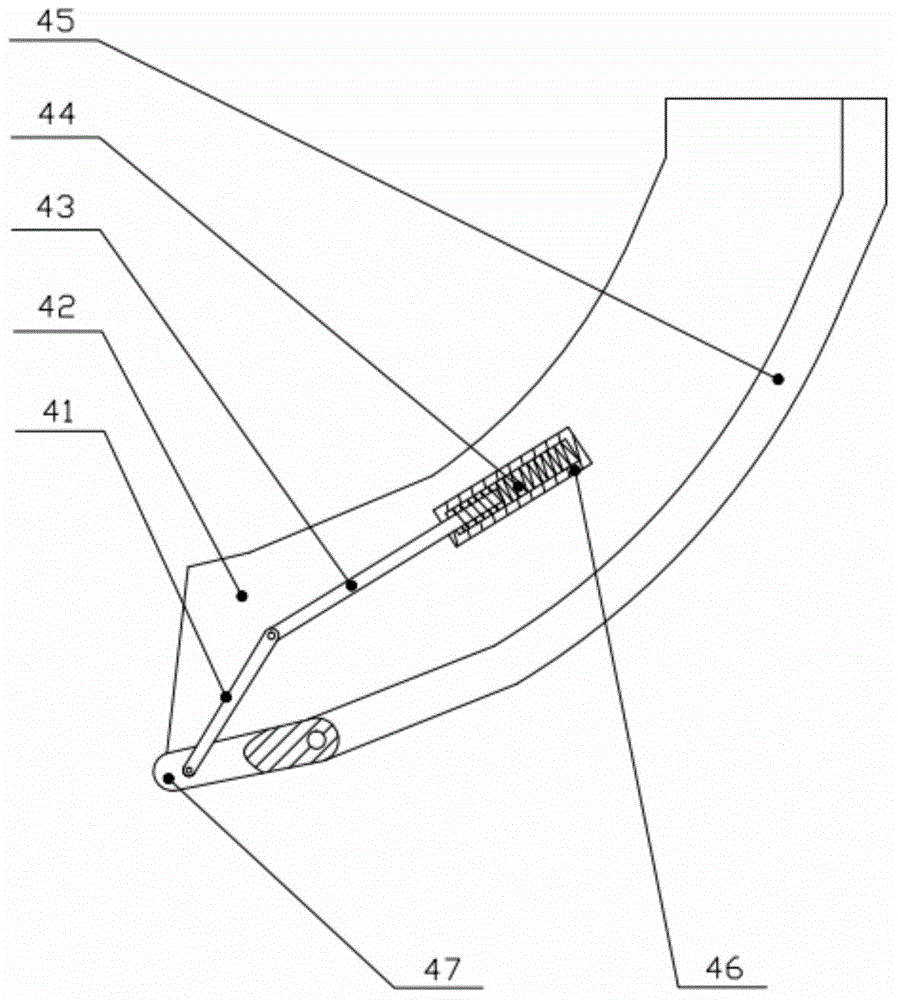

[0012] For device layout see figure 1 , figure 2 , image 3 . Front plate 1 is connected on the rear groove 25 by bolts, and the rotating shaft of rolling brush 2 is connected in the bearing seat of car body 18 front ends by bearing, and rolling brush cover 3 is fixed on the rear groove 25 by screwing. Screw rod cover 4 one ends are connected on the back groove 25 by screw, and the other end is connected on the vehicle frame of car body 18, and spiral pipe cover 4 is inclined 48 degrees and is installed in the middle of car body 18. Screw rod 6 one ends are connected in the bearing seat of rear groove 25 by cylindrical roller bearing 2 24, and the other end is connected in the bearing seat of screw rod cover 4 by bearing. One end of the turbine shaft 8 cooperates with the internal thread of the screw rod 6, and the other end is connected in the bearing seat of the turbine and worm casing 40 through a cylindrical roller bearing-7. The turbine 9 is keyed to the turbine shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com