Clamping and conveying mechanism for cement feeding bucket

A technology for handling mechanisms and feeding barrels, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as time-consuming, labor-intensive, safety hazards, and low efficiency, and achieve good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

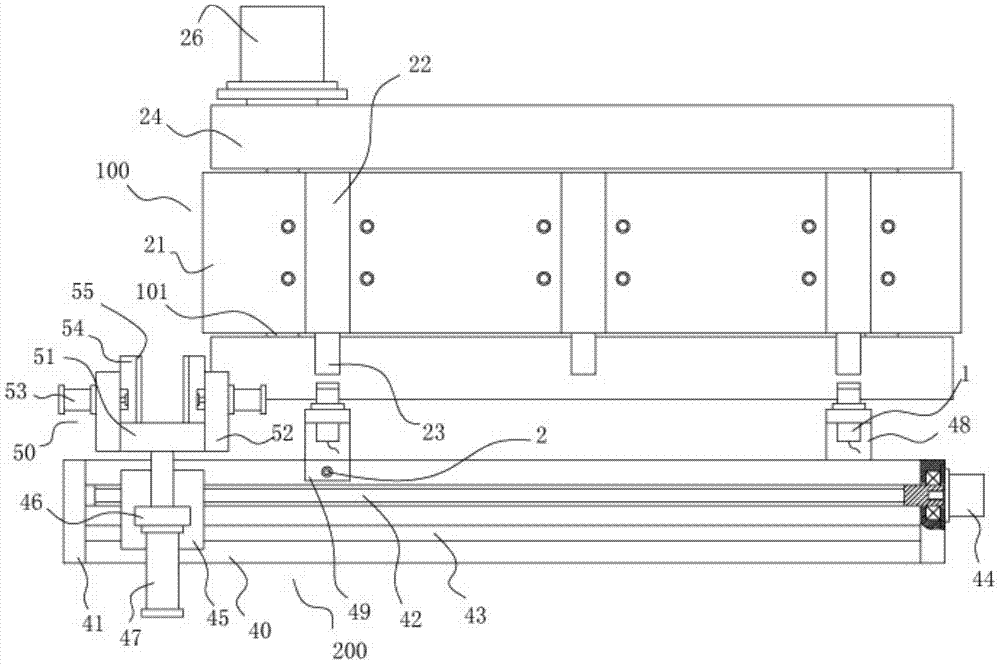

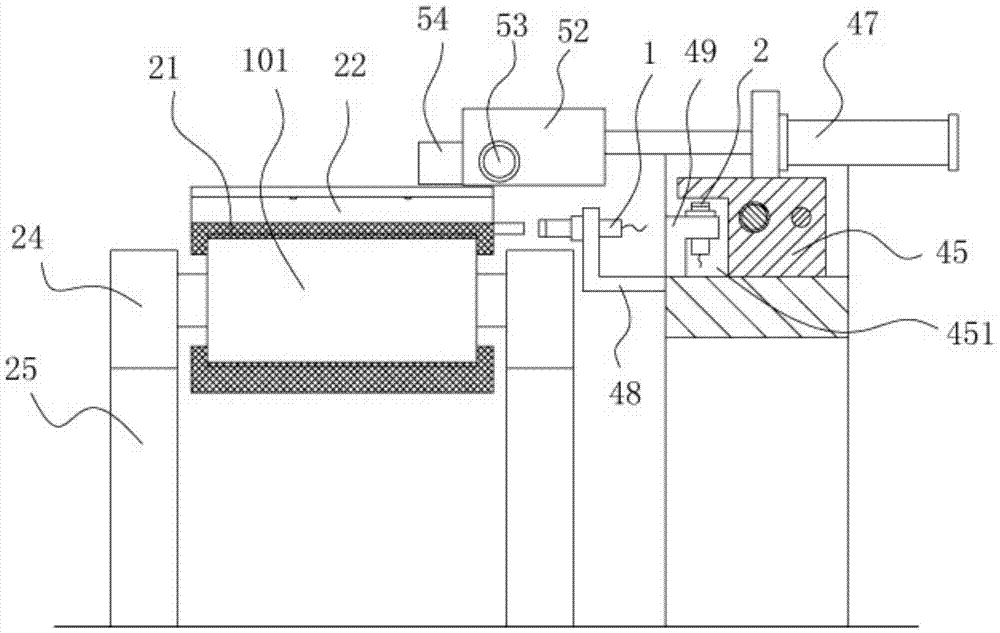

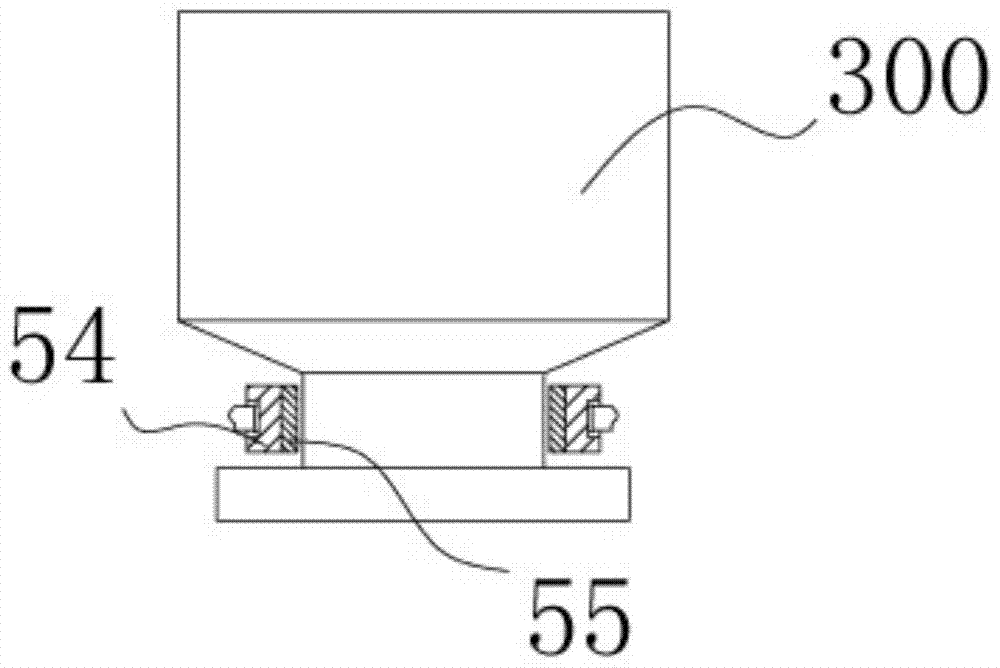

[0014] Example: see Figures 1 to 3 As shown, a clamping and conveying mechanism for a cement feeding bucket includes a conveying frame body 100 and a clamping and conveying mechanism 200. The clamping and conveying mechanism 200 is on one side of the conveying frame body 100, and the conveyor belt of the conveying frame body 100 The outer wall surface of 21 is evenly distributed with a plurality of convex-shaped slots 22, and the side wall of the bottom surface of each convex-shaped slot 22 has an induction protrusion 23; Two ends of the top surface of the frame 40 are fixed with two movable support plates 41, the two ends of the drive screw 42 are hinged on the two movable support plates 41, and the two ends of the transverse slide bar 43 are fixed on the two movable support plates 41, One of the mobile support plates 41 is fixed with a total drive motor 44, the output shaft of the total drive motor 44 is a spline shaft, and the spline shaft is inserted in the spline hole th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com