Self-propelled hydraulic T-shaped beam prefabricating template device and demolding method thereof

A self-propelled, formwork technology, applied in the direction of unloading devices, molds, manufacturing tools, etc., to achieve the effect of reducing production costs, coordinated and consistent actions, and saving time and effort in automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

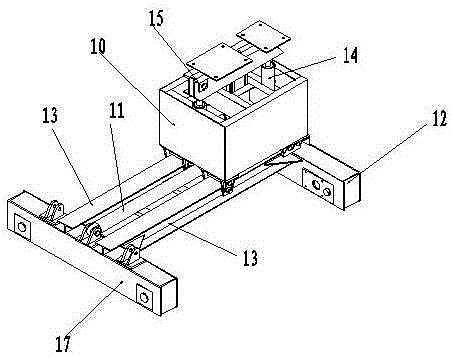

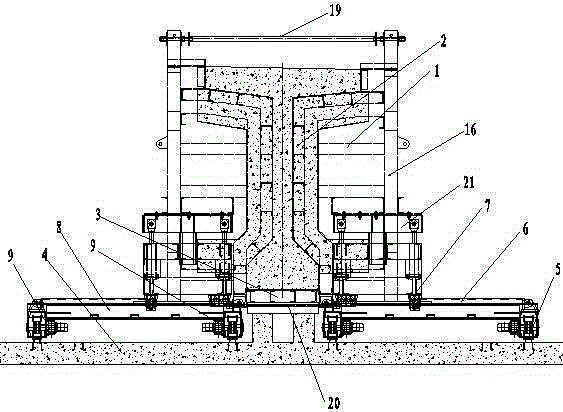

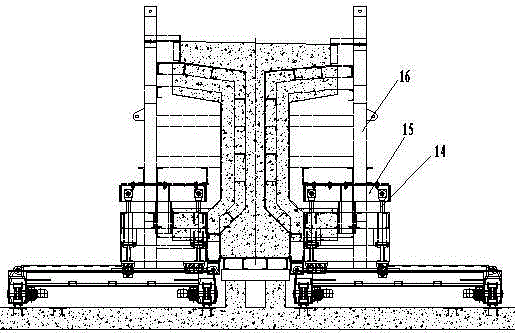

[0021] Figure 1-6 As an embodiment of the present invention, this embodiment is specifically described in conjunction with the accompanying drawings, including a formwork device composed of a side form device 1, an end form device 2 and a bottom form device 3, on the concrete foundation surfaces on both sides of the side form device 1 Guide rails 5 are set, frame-type longitudinally moving car bodies 8 are installed on the guide rails 5 on both sides of the frame-type longitudinally moving car body 8, and LDA-type drive units are arranged symmetrically on the inner longitudinal frame body 12 and the outer longitudinal frame body 17 on both sides of the frame-type longitudinally moving car body 8. The device 9 drives the frame-type longitudinally moving car body 8 to move longitudinally along the guide rail through the LDA type driving device, and sets the laterally moving car body 10 on the transverse frame body 13 of the frame-type longitudinally moving car body 8, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com