Novel guiding column and guiding sleeve

A guide post and guide sleeve technology, which is applied in the field of new guide posts and guide sleeves, can solve the problems of damage and disassembly of the guide post or guide sleeve, damage to the guide post and guide sleeve, and difficulty in installation, so as to reduce the production cost and achieve the combination accuracy. High, interchangeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

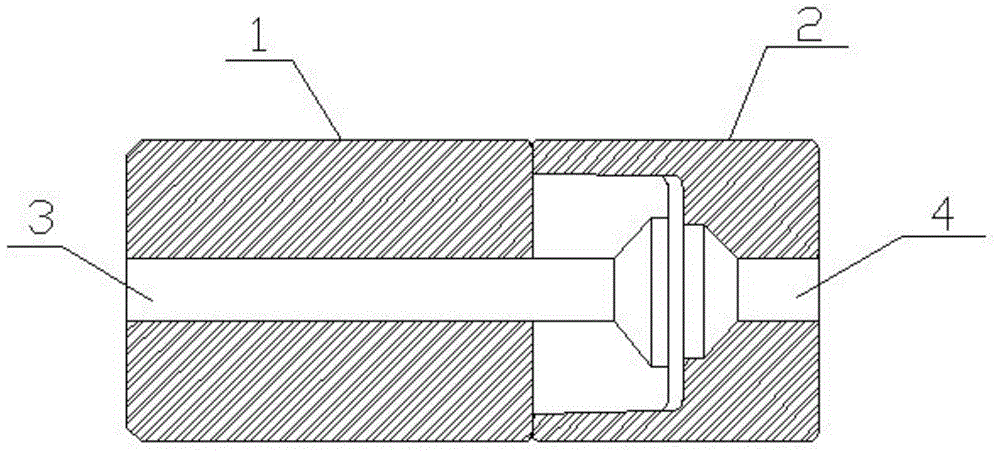

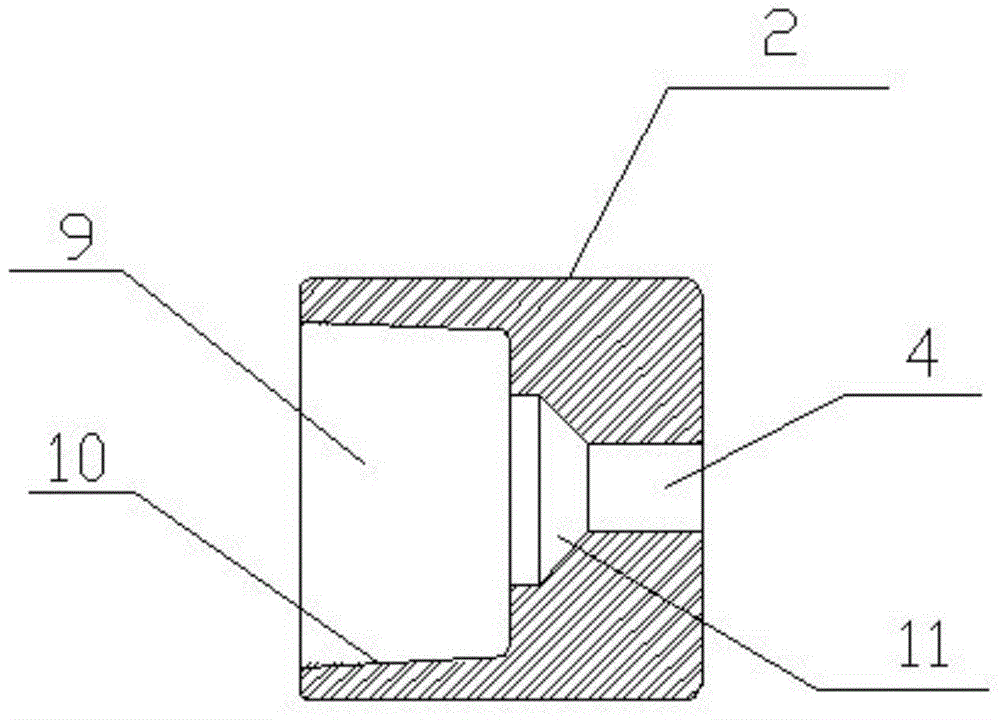

[0019] Such as figure 1 , figure 2 , image 3 As shown, a new guide post and guide sleeve, including a guide post 1 and a guide sleeve 2 cooperating with the guide post 1, the diameter of the guide post 1 ranges from 10-50mm, and the length of the guide post 1 ranges from 20-80mm , Guide post 1 and guide sleeve 2 are made of S136 mold steel, after vacuum heat treatment, the hardness reaches HRC54-56, wear-resistant and anti-rust, and has a long service life. The edges of the left and right sides of the guide post 1 are provided with chamfers. The guide post 1 includes a cylinder 6 and an outer cone 5 arranged on the right side of the cylinder 6. The cylinder 6 is provided with a first standard metric internal thread 3 , the first standard metric internal thread 3 is set at the center of the cylinder 6, the outer wall of the outer cone 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com