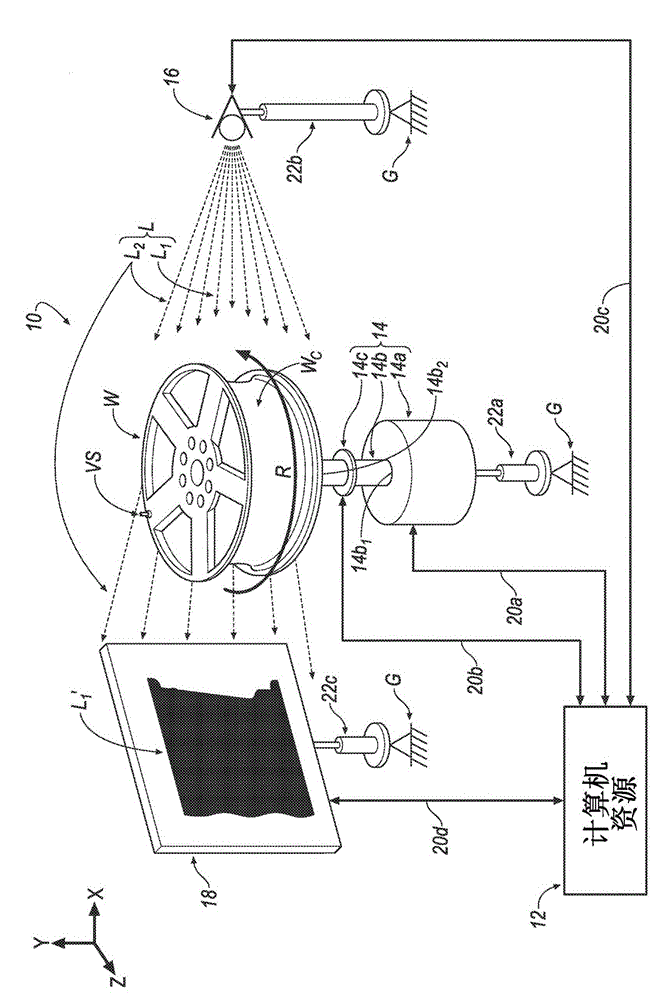

Uniformity testing system and methodology for utilizing the same

A test system, uniformity technology, used in wheel testing, automotive tire testing, optical testing for flaws/defects, etc., which can solve problems such as large capital investment and human supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Before describing embodiments of the invention, refer to Figures 4A-4D , which illustrates an exemplary tire T. Further, in describing the embodiments of the present invention, "upper", "lower", "left", "right", and "side" of the tire T may be referred to. Although such terms may be used to describe specific portions or aspects of the tire T, such terms may be employed with respect to the orientation of the mechanism for supporting / engaging the tire T (the implement rotating device 14). Accordingly, the above terms should not be used to limit the scope of the present invention, but are used herein for exemplary purposes of describing embodiments of the present invention.

[0052] In one embodiment, the tire T includes an upper sidewall surface T SU (For example, see Figure 4A ), the lower side wall surface T SL (For example, see Figure 4D ) and the upper side wall surface T SU with lower sidewall surface T SL Combined tread T T (For example, see Figures 4B-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com