An automatic installation device for acoustic module shrapnel

An automatic installation and module technology, applied in the direction of sensors, electrical components, etc., can solve the problems that the product quality and technical proficiency level is greatly affected, the product quality reliability cannot be guaranteed, and the production cost of the enterprise is increased, so as to achieve ingenious structure and reliable guarantee Sexuality, convenient discharge alarm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

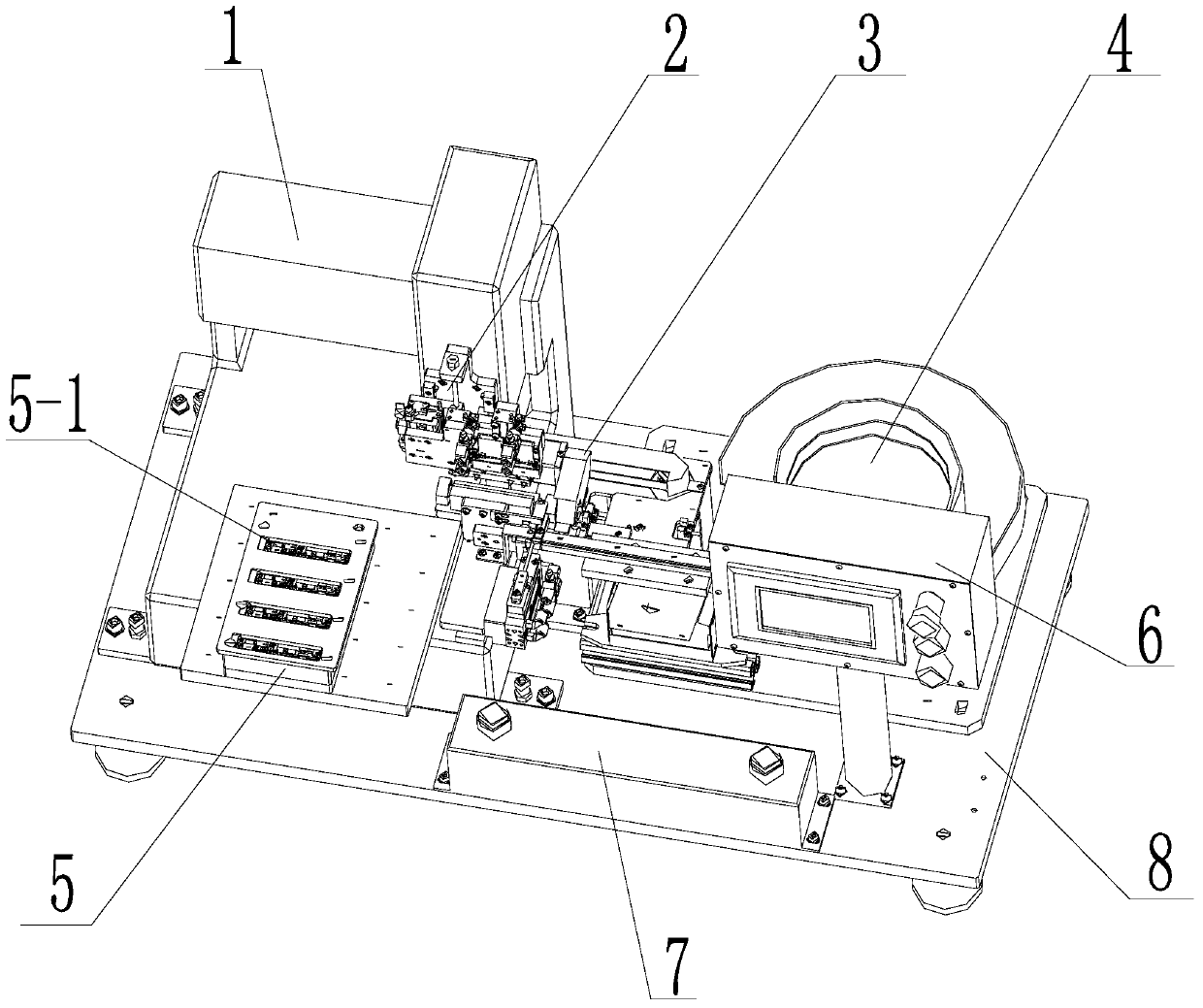

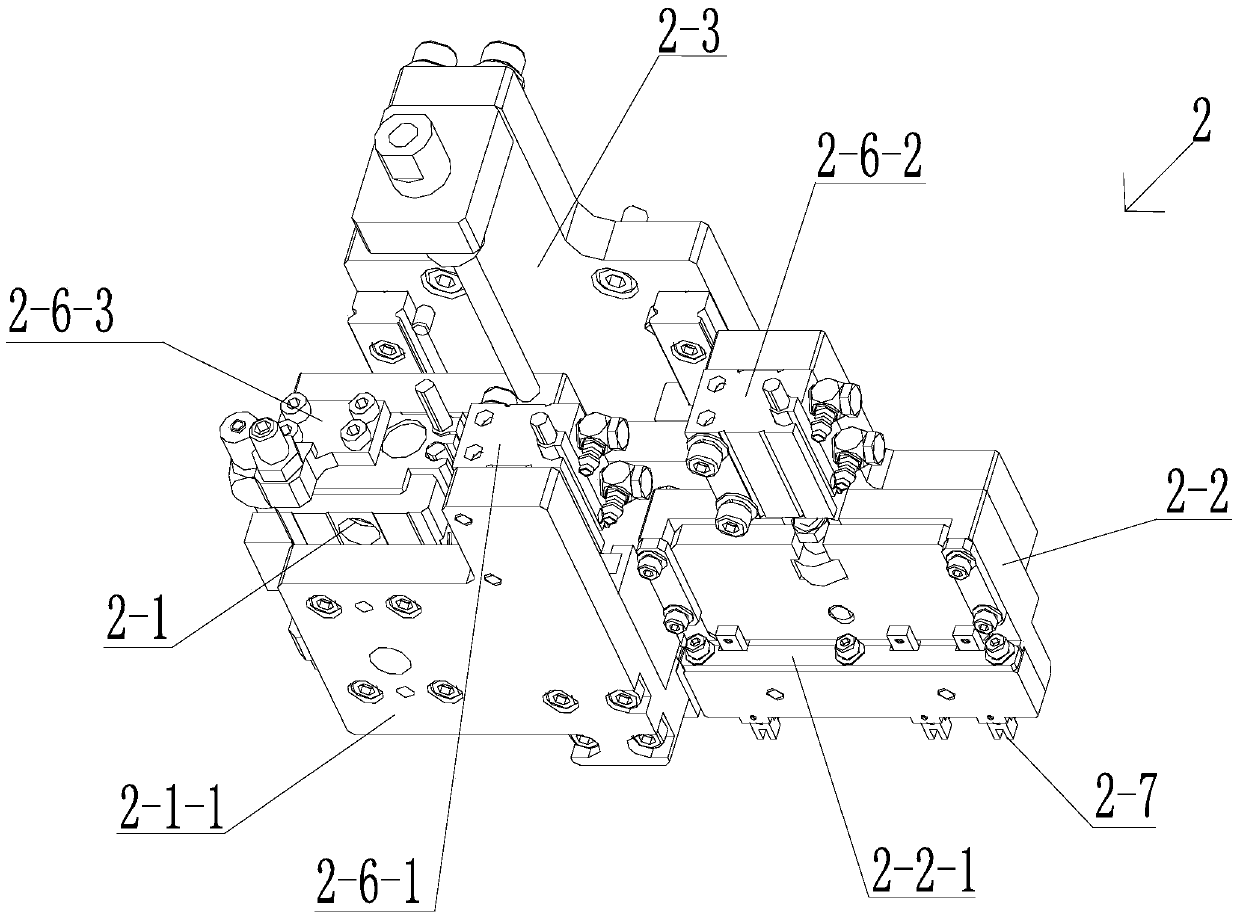

[0032] Such as figure 1 As shown, an acoustic module shrapnel automatic installation device includes a base plate assembly 8, a dispensing machine assembly 1 is arranged on the base plate assembly 8, and a tooling assembly 5 is provided on the workbench of the dispensing machine assembly 1, The tooling assembly 5 is provided with a plurality of acoustic module placement slots 5 - 1 , and the gantry traveling device of the dispenser assembly 1 is provided with a feeding and pressing assembly 2 .

[0033] The bottom plate assembly 8 is provided with a feeder 4 .

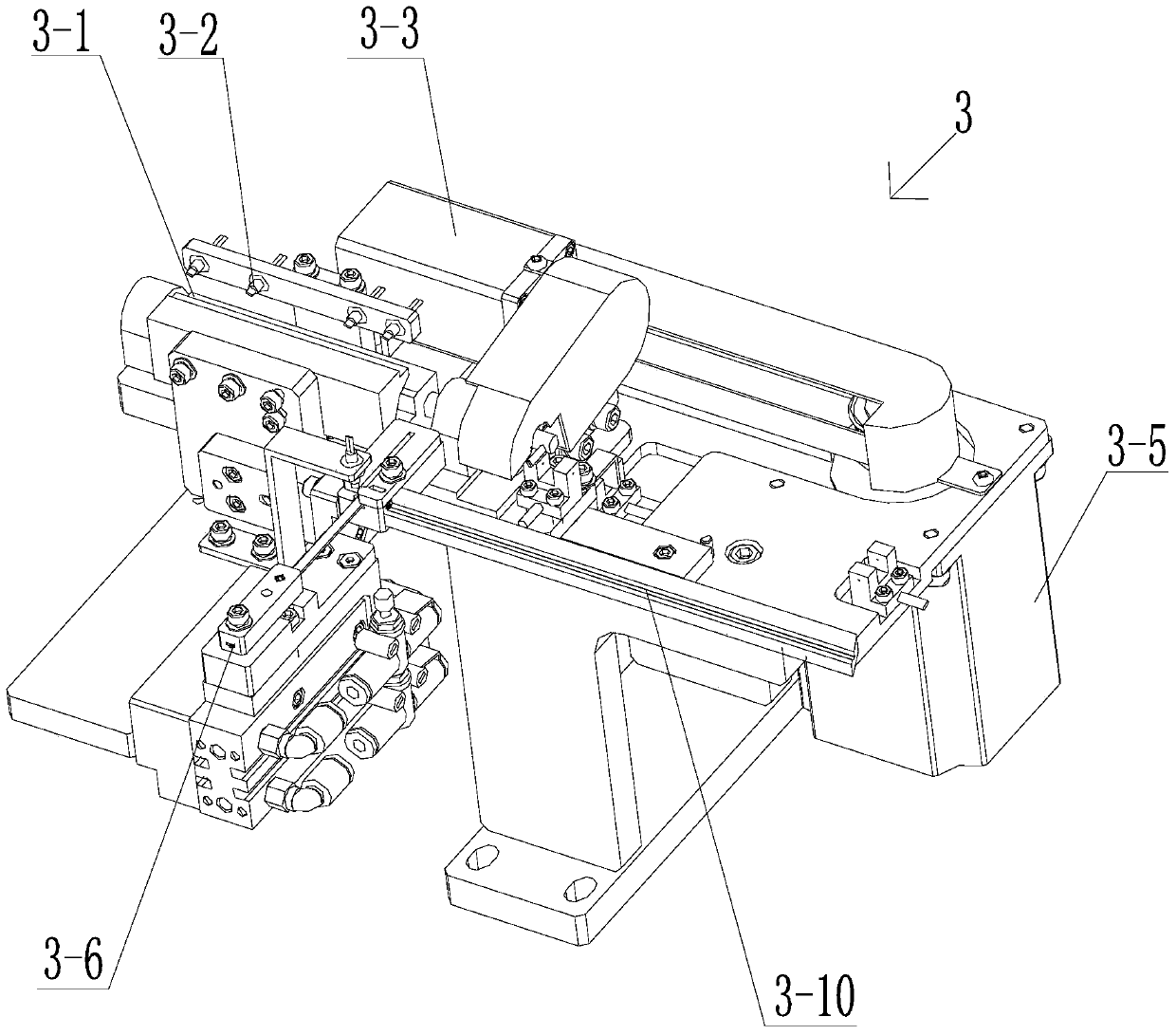

[0034] The bottom plate assembly 8 is provided with a distribution detection mechanism 3, the feed end of the distribution detection mechanism 3 is docked with the discharge end of the feeder 4, and the detection end of the distribution detection mechanism 3 is connected to the The feeding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com