An intelligent high-precision PTZ control system

A control system, high-precision technology, applied in the field of PTZ, can solve the problems of PTZ jitter, poor camera image quality, torque ripple, etc., to solve the problems of poor running stability, low positioning accuracy, and accurate acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

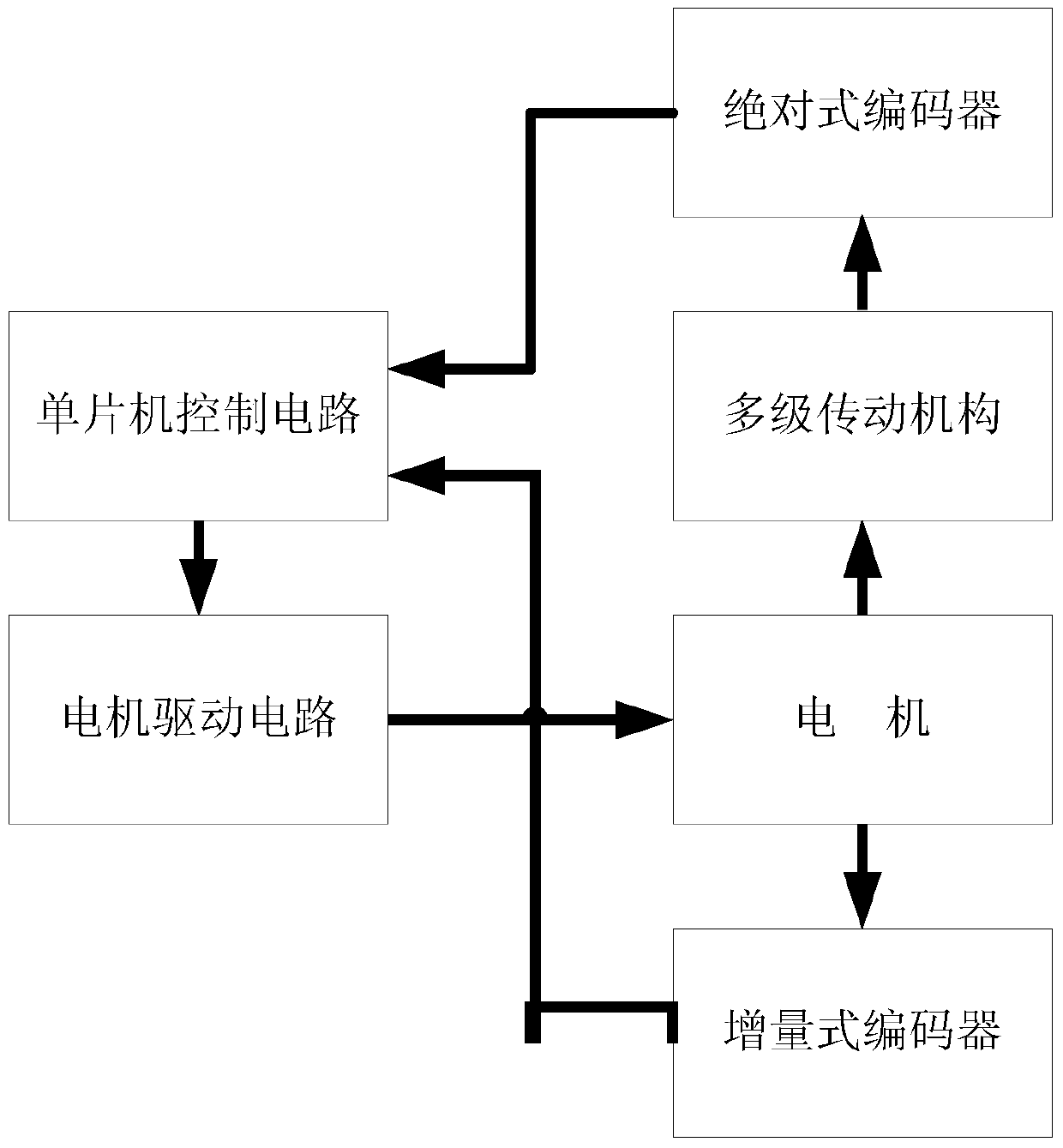

[0017] Such as figure 1 As shown, the present invention discloses an intelligent high-precision pan-tilt control system, including a motor, a multi-stage transmission mechanism, an incremental encoder, an absolute encoder, a motor drive circuit and a single-chip microcomputer control circuit, and the incremental encoder and Absolute encoders are respectively installed on the motor end and the multi-stage transmission mechanism end, and the motor speed and the specific position of the multi-stage transmission mechanism are obtained in real time through the incremental encoder and the absolute encoder, and the relevant parameters are fed back to the single-chip control in time circuit, the single-chip microcomputer control circuit optimizes the control of the motor through the motor drive circuit, and the intelligent high-precision pan-tilt contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com