Lining machine for mobile phone polarizer with reliable alignment

A technology of polarizers and laminating machines, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as inconvenient processes, cracking of glass substrates, and difficult control, so as to save time and workload, reduce residual air bubbles, The effect of improving the bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

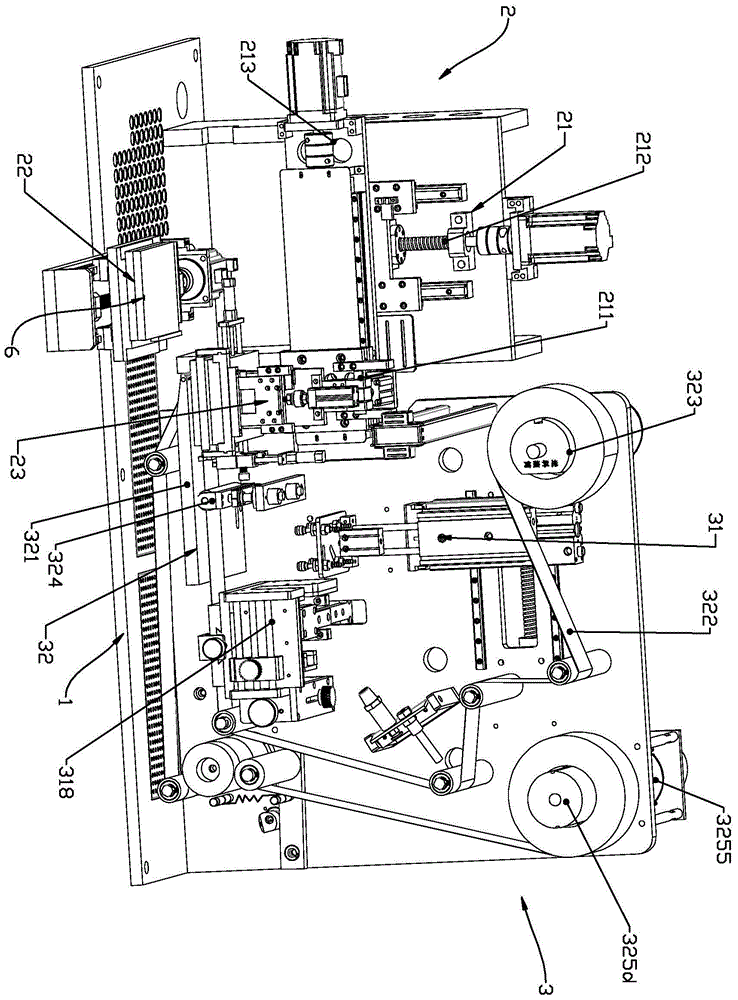

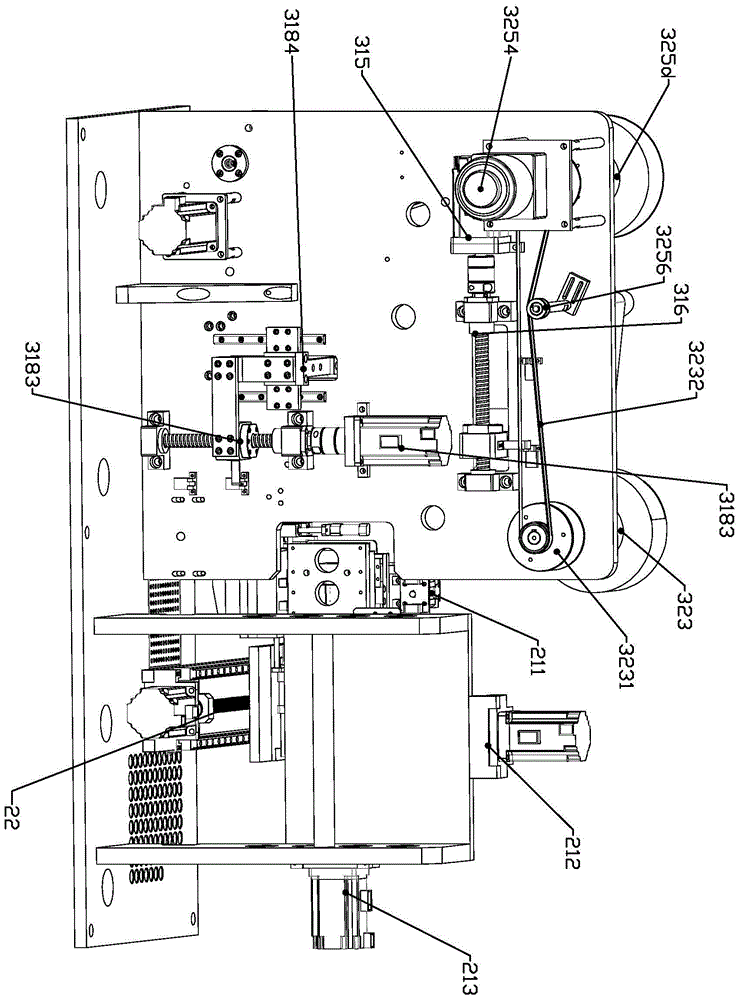

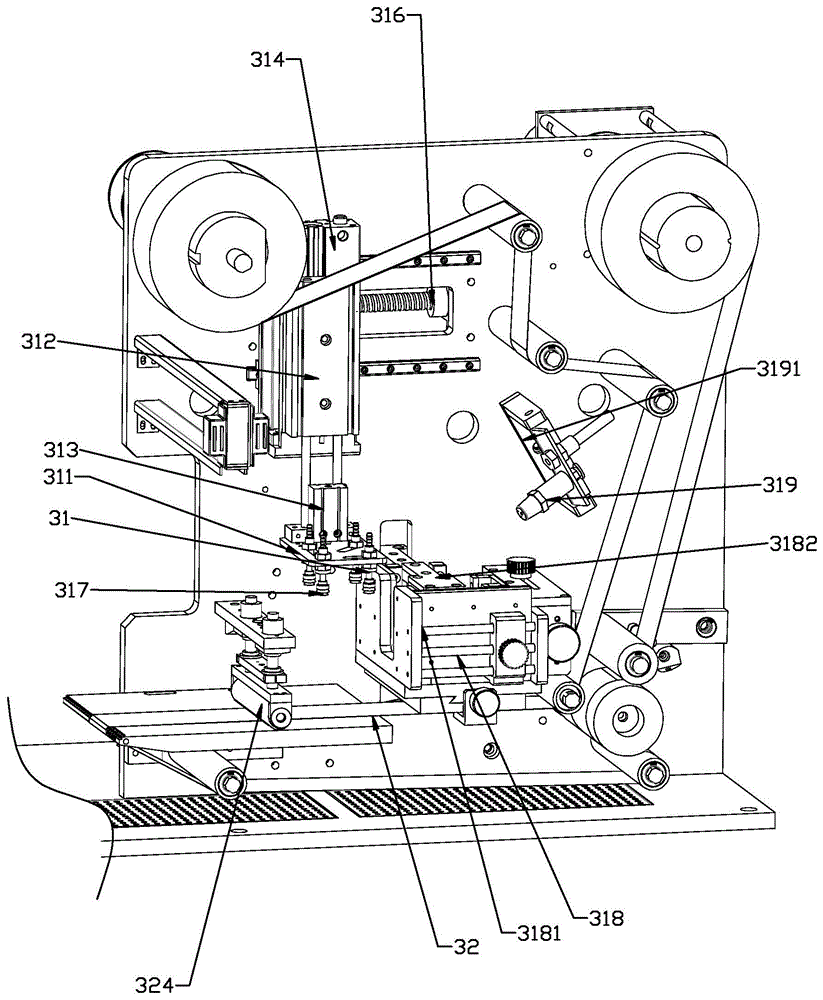

[0033] Such as Figure 1~Figure 7 As shown, a mobile phone polarizer laminating machine with reliable alignment disclosed by the present invention includes an organic base and a placement device 2 installed on the base 1. The placement device 2 includes a polarizer for absorbing and fixing the polarizer. Sheet loading mechanism 21, substrate loading mechanism 22 for absorbing and fixing glass substrates, and chip rolling mechanism 23 for rolling after polarizers and glass substrates are pre-attached. A polarizer automatic feeding device 3 for automatic sheet feeding and film removal. The substrate loading mechanism 22 includes a vacuum suction seat 223 for positioning and fixing the glass substrate. The alignment detection probe 6, the alignment detection probe 6 can be an infrared detection probe, or a photoelectric detection probe, and the detection probe 6 ensures a reliable positioning before the patch to ensure that the patch is reliable. The polarizer loading mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com