As-fired coal separate bin metering system of coal conveying system

A technology of coal conveying system and metering system, applied in the field of coal conveying system, can solve the problems of inability to accurately measure the economic benefits of boilers, difficulty in burning indicators of a single boiler, etc., and achieve the effects of convenient operation, avoiding errors and improving proportional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

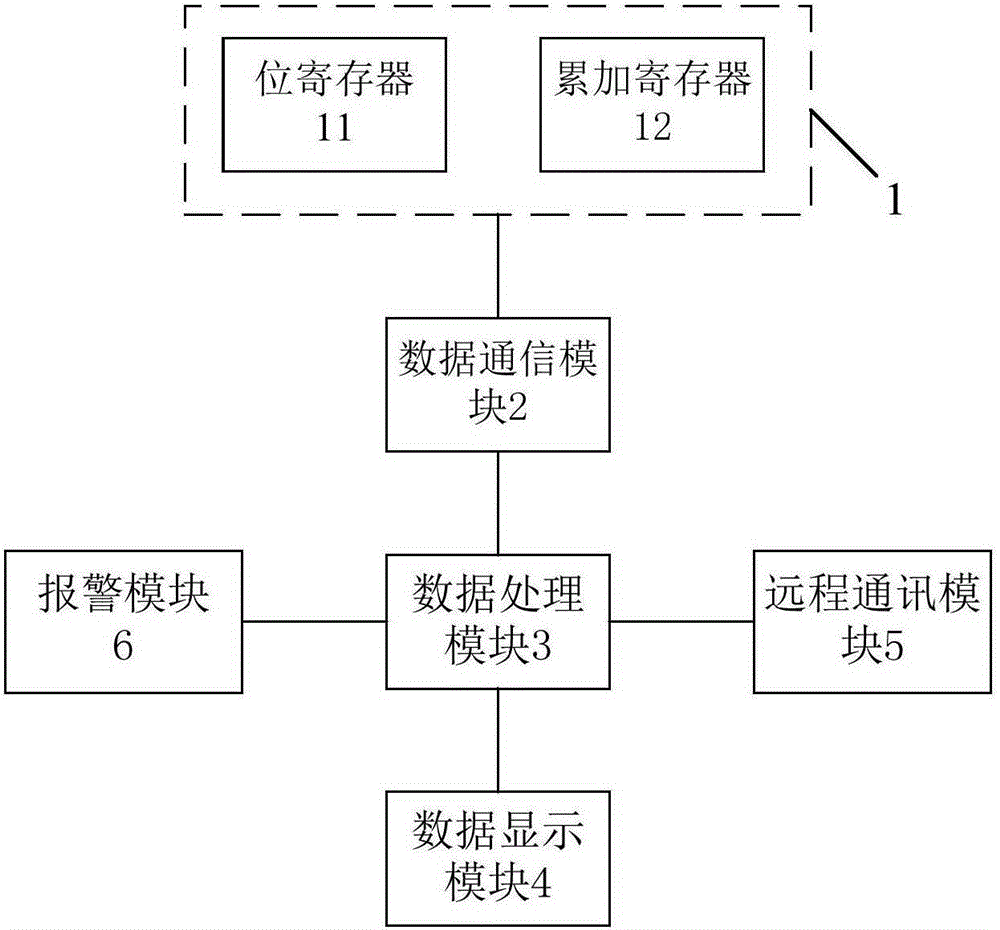

[0029] Such as figure 1 As shown, a coal conveying system into the furnace coal sub-bin metering system, including:

[0030] Adding volume data acquisition module 1, set on each raw coal bunker, is used to collect the real-time coal adding amount and cumulative coal adding amount information of each raw coal bunker;

[0031] The data communication module 2 is connected with the data acquisition module of the warehouse increase amount, and is used to transmit the data of the warehouse increase amount data acquisition module;

[0032] The data processing module 3 is connected with the data communication module, and receives the real-time coal addition information and the accumulated coal addition information transmitted by the data communication module;

[0033] The data display module 4 is connected with the data processing module and is used to display the current coal loading information and the accumulated coal loading information of each raw coal bunker.

[0034] The data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com