A caliper tooling

A tooling and caliper technology, applied in the direction of mechanical diameter measurement, can solve the problem of high cost of measuring calipers, and achieve the effects of simple structure, reliable action, and simple limit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

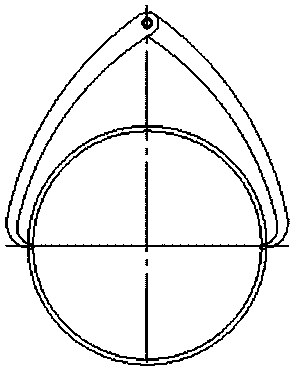

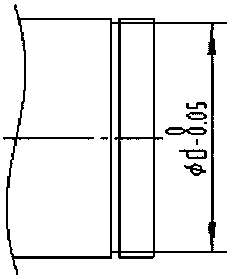

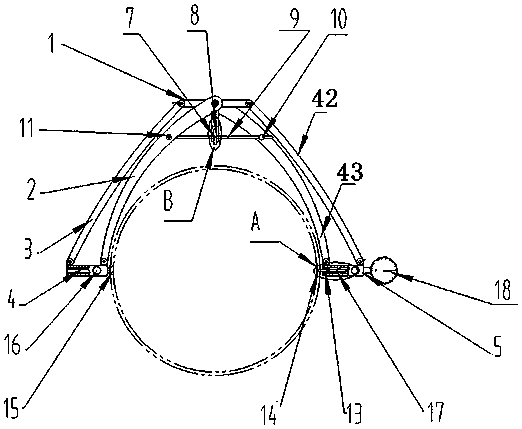

[0040] Such as Figure 3 to Figure 13 As shown, an embodiment of a caliper tool, the caliper tool in this embodiment is specifically an outer circular caliper, which includes two parallel four-bar linkages arranged along the left and right directions and assembled together, the two parallel four-bar linkages are left Side parallel four-bar linkage mechanism 100 and right side parallel four-bar linkage mechanism 200, each parallel four-bar linkage mechanism includes an upper link, a lower link and two middle links, and two upper links of two parallel four-bar linkage mechanisms The upper link assembly 1 is formed as an integral structure, and the connection line between the upper link in each parallel four-bar linkage mechanism and the two hinge points hinged with the corresponding two intermediate links is the upper hinge point connection line, and the upper link with the lower link. The line connecting the two hinge points of the corresponding two intermediate links is the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com