Pin shaft

A technology of pin shaft and axis, applied in the field of hinged structure, can solve the problems of excessive clearance, unstable rock drilling arm, and inaccurate positioning of rock drill holes, and achieve the effect of eliminating clearance, improving service life and connection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

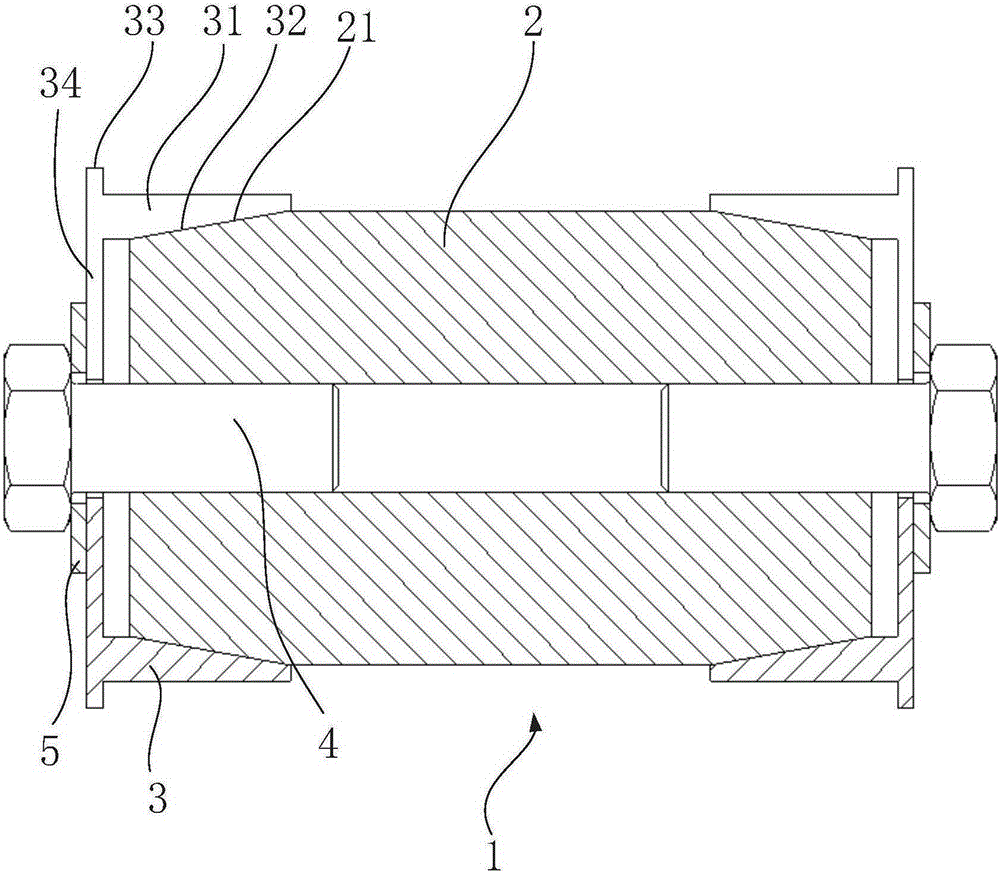

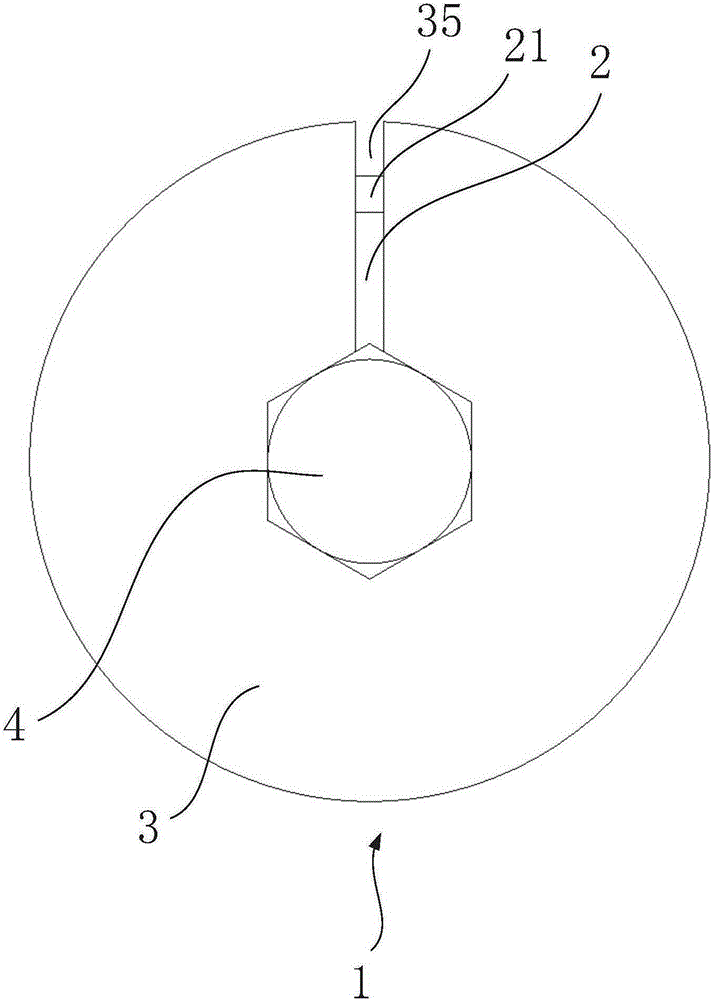

[0021] figure 1 The structure of pin shaft 1 in one embodiment of the present invention is shown. The pin shaft 1 includes a body 2 , an expansion sleeve 3 fitted on the body 2 , and a fixing piece 4 for relatively fixing the body 2 and the expansion sleeve 3 . The pin shaft 1 is mainly used for positioning and / or transmission between two components. It is especially suitable for the positioning and transmission between two hinged seats, and transmits the interaction force between the two hinged seats. In the following, the pin shaft 1 is installed in the pin shaft hole of the hinge seat as an example to describe in detail.

[0022] The body 2 is configured as a substantially cylindrical structure. The main body 2 is the skeleton structure of the pin shaft 1, bearing the radial shear force exerted on the pin shaft 1 by the two hinge seats respectively. The body 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com