Designing method for hydraulic power of space guide-blade centrifugal pump

A space guide vane, hydraulic design technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of low efficiency, uncontrollable, large hydraulic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The empirical coefficients and recommended values of this embodiment are obtained through the correction of a large number of experimental statistical data, that is, the conventional empirical values used by those skilled in the art; the final design values need to be checked by numerical calculation results.

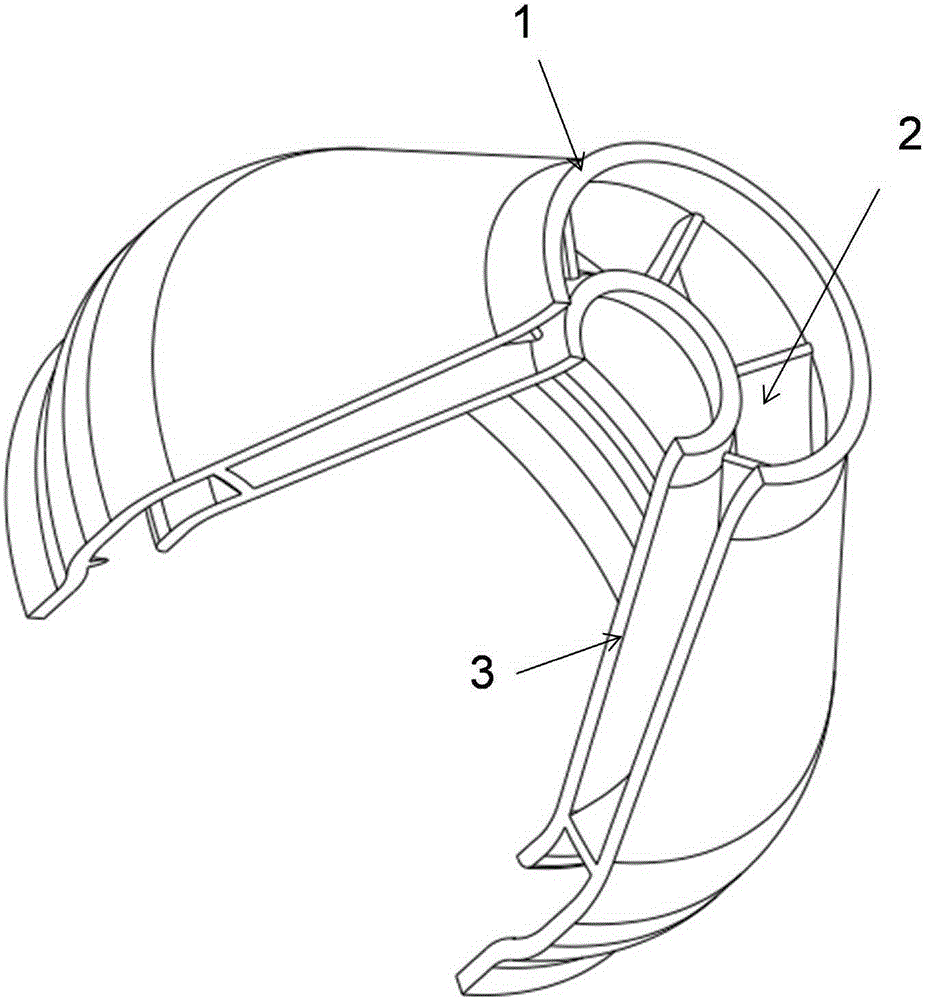

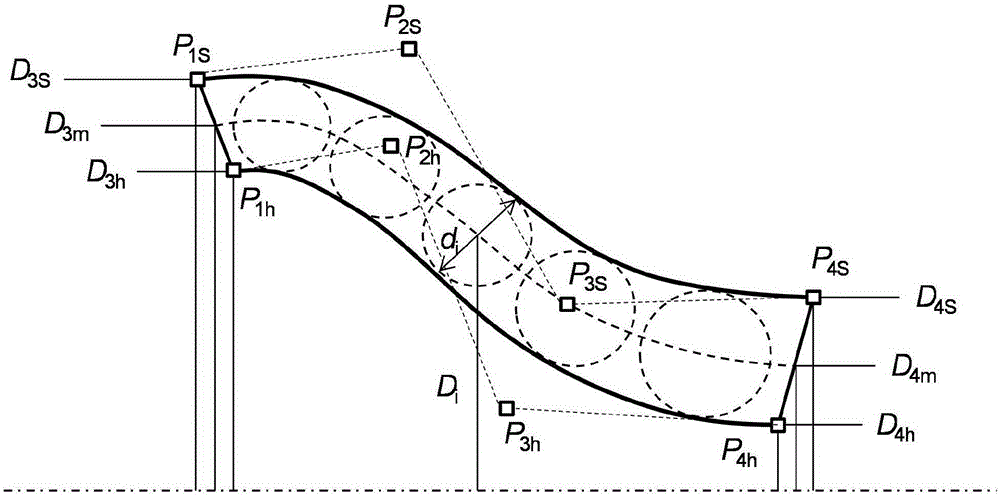

[0054] to combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , a hydraulic design method of a space guide vane centrifugal pump in this embodiment, wherein the hydraulic structure of the impeller includes a front cover 1, blades 2 and a rear cover 3, such as figure 1 Shown; comprise the following steps: 1) according to given impeller geometry parameter and flow rate, head and rotating speed value, solve space guide vane axial surface hydraulic design parameter based on binary flow theory, describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com