Air engine powered by natural gas

An air engine and natural gas technology, which is applied in variable displacement engines, machine/engines, reciprocating piston engines, etc., can solve the problems of gas engines with complex structures and not having the advantages of air motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

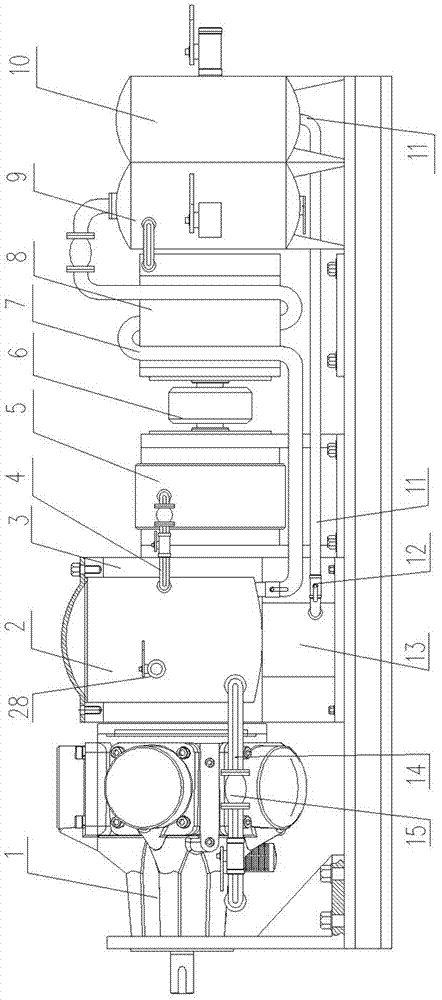

[0011] like figure 1 As shown, the air engine of the present invention includes a first air motor 1 (the first air motor 1 is a piston air motor), a natural gas storage tank 10, an air storage tank 9 and a heating tank 2, wherein the first air motor 1 is used as Power source output, the natural gas storage tank 10 is used to store natural gas, the air storage tank 9 is used to store compressed air, and the heating tank 2 is also used to store compressed air, except that the heating tank 2 also needs to heat the compressed air , the heating of the heating tank 2 is realized by the natural gas heater 13, and the natural gas heater 13 is connected with the natural gas heater 13 through the natural gas pipeline 11, thereby providing fuel for the natural gas heater 13; after heating in the heating tank 2 The compressed air is delivered to the first air motor 1 through the first air pipeline 14, so that the first air motor 1 obtains an air source, thereby realizing power output; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com