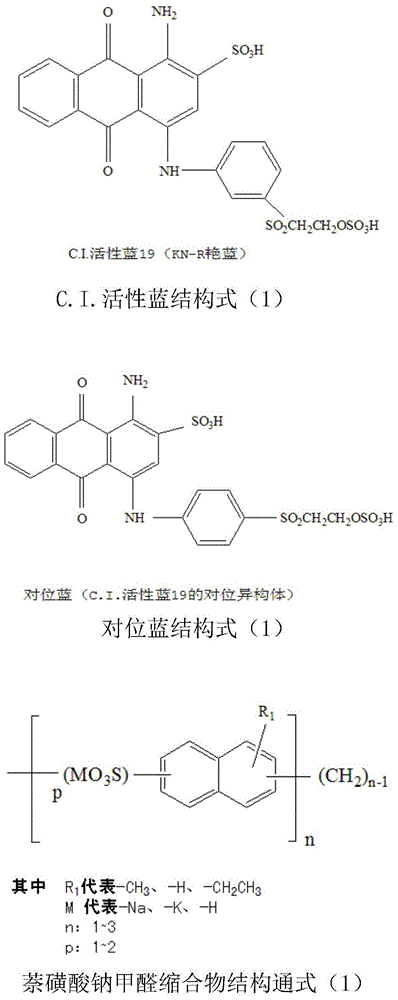

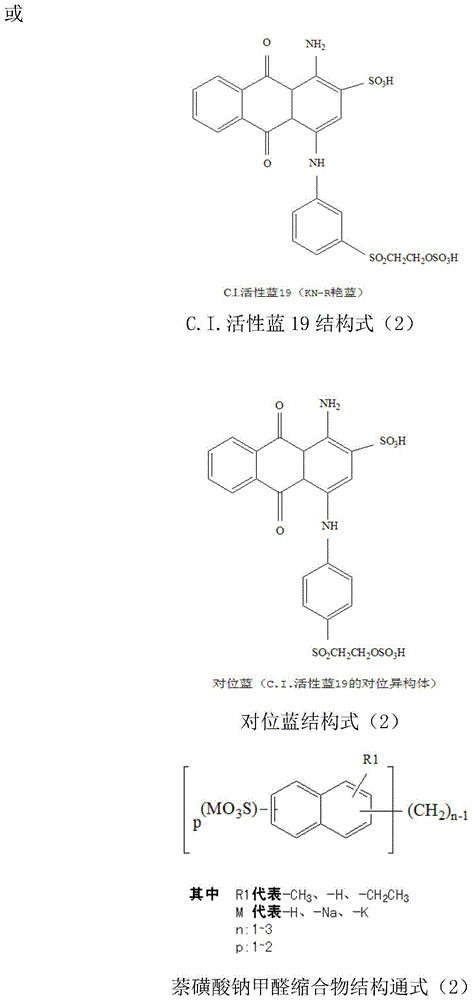

High saline alkali reactive brilliant blue KN-RSR dye composition and preparation method thereof

A technology of dye composition and reactive brilliant blue, which is applied in the fields of dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of easy association between reactive brilliant blue molecules, hydrolysis, etc., and achieve good level dyeing and dyeing properties. Deep performance, enhance performance, improve the effect of poor salt and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

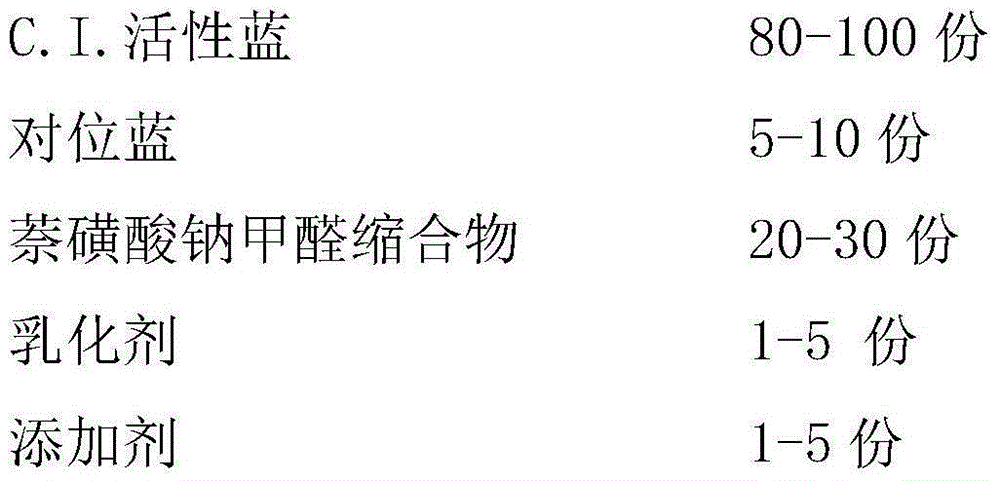

[0020] Weigh 100g reactive brilliant blue KN-RSR (strength 125%), 10g para blue (strength 120%), 30g naphthalenesulfonic acid formaldehyde condensate, 1g of 1-2 components of additives C1-C12, sodium hexametaphosphate 0.5g, 1g of emulsifier, 0.5g of dustproof agent, and fully mixed to prepare the dye composition of the present invention: reactive brilliant blue KN-RSR100%. Example 2:

Embodiment 2

[0021] Weigh 100g reactive brilliant blue KN-RSR (strength 125%), 8g para blue (strength 120%), 20g naphthalenesulfonic acid formaldehyde condensate, 1g of 1-2 components of additives C1-C12, sodium hexametaphosphate 0.5g, 1g of emulsifier, 0.5g of dustproof agent, and fully mixed to prepare the dye composition of the present invention: reactive brilliant blue KN-RSR120%.

[0022] The reactive brilliant blue KN-RSR of the present invention is compared with the conventional reactive brilliant blue KN-R and Sumitomo Sumifix Brilliant Blue Special of Japan for salt and alkali resistance test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com