An automatic mobile phone film sticking film vending machine and its automatic film sticking film vending method

A technology for cell phone filming and vending, which is applied to instruments, coin-operated equipment for distributing discrete items, packaging, etc. It can solve the problems of poor compatibility of protective films, waste of filming, and easy sticking of dust, and improve the compatibility of original films. , Reduce the intermediate cost and increase the effect of film accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

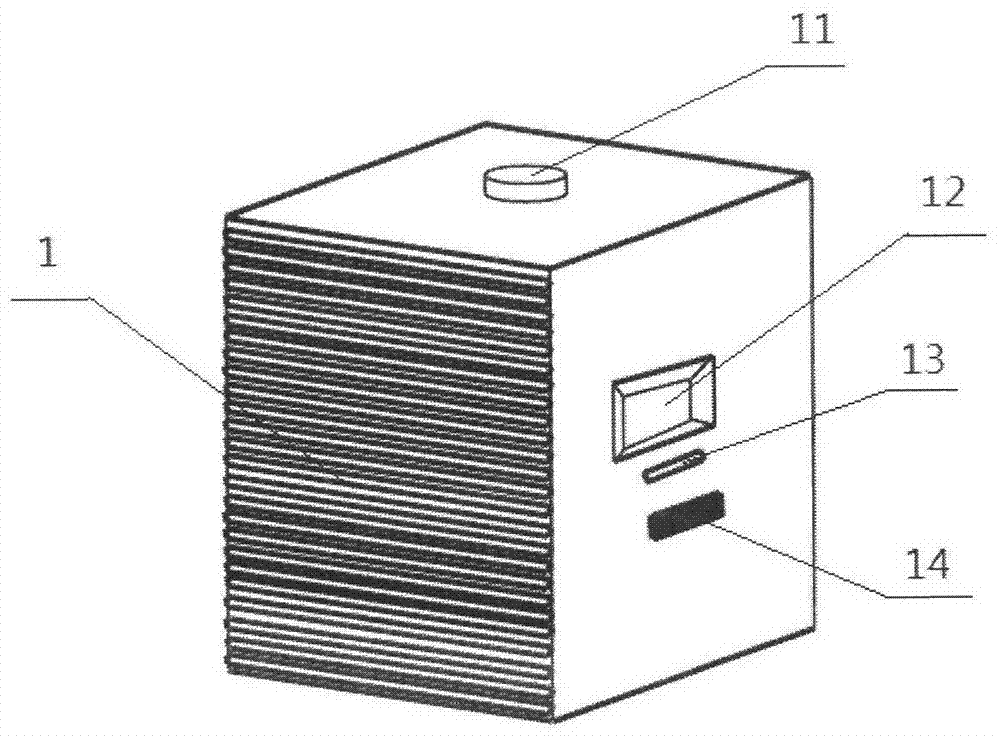

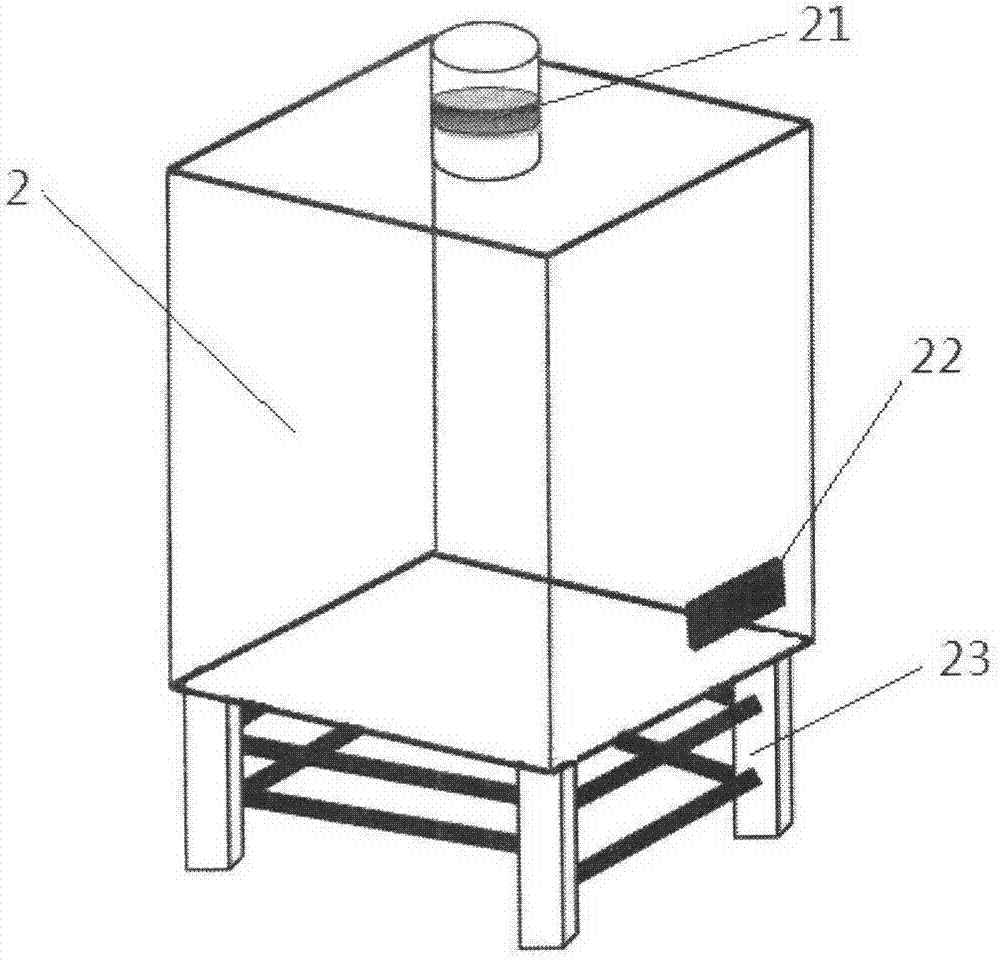

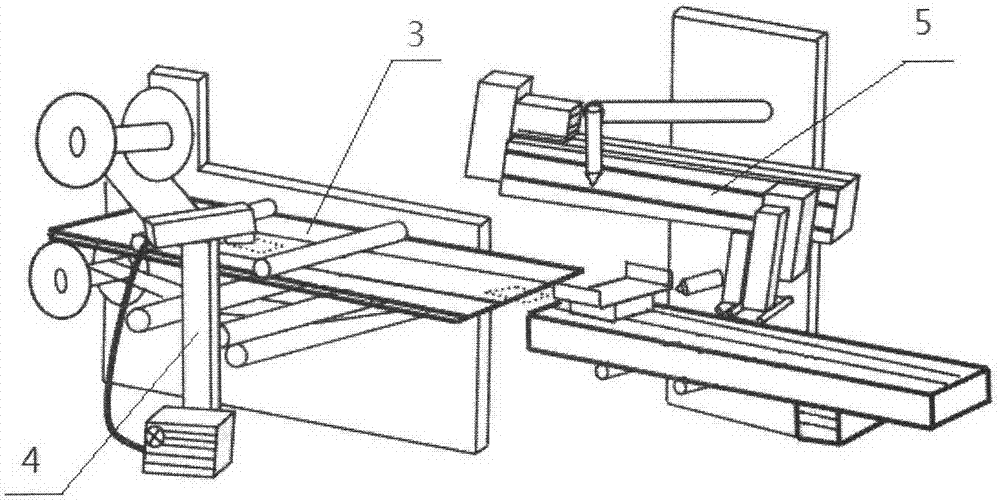

[0042] Such as figure 1 , 2 , 3, an automatic film vending machine for mobile phones, comprising an automatic vending device 1, a glass clean room 2, a feeding device 3, a laser device 4, and a laminating device 5, the feeding device 3, the laser device 4, the pasting device The bonding device 5 is placed in the glass clean room 2, and the glass clean room 2 is placed in the automatic vending device 1; the laser device 4 is located on the left side of the feeding device 3, and the bonding device 5 is located The right end of described feeding device 3; The laser head 43 of described laser device 4 tops is facing the laser area 34 of the original film 37 on the cutting conveying platform 36 of described feeding device 3, and the right end of descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com