Mounting seat for hinged mechanism of low-floor tram

A technology of articulated mechanism and tram, which is applied in the direction of transportation and packaging, railway car body parts, railway couplings, etc., which can solve problems such as troublesome production process, inconvenient installation and maintenance, and difficult installation and coordination, so as to reduce the overall Quality, easy installation and maintenance, and high installation coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

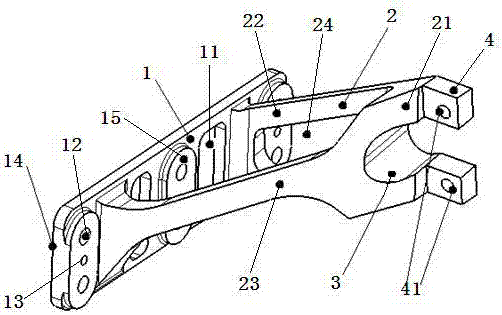

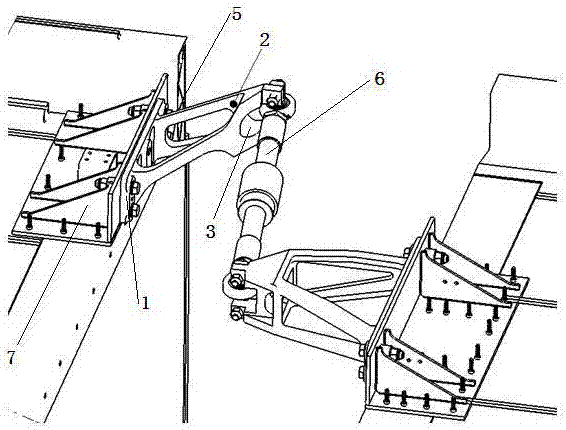

[0037] Such as figure 1 and figure 2 As shown, a low-floor tram hinge mechanism mounting seat is used for the cooperative installation between the car body module 5 and the hinge mechanism 6, which includes a car body mounting plate 1 and a trapezoidal connecting column 2.

[0038] At least two bolt-fixing surfaces 15 , preferably three bolt-fixing surfaces 15 are provided on one side of the above-mentioned vehicle body mounting plate 1 away from the vehicle body connecting surface 14 . The three bolt mounting surfaces 15 are located at the two ends and the middle of the vehicle body mounting plate 1 respectively, and two bolt holes 12 are preferably arranged on the three bolt mounting surfaces 15, wherein the bolt fixing surfaces 15 located at both ends of the vehicle body mounting plate 1 At least one cylindrical pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com