Automatic control color card coating and printing machine

A printing machine and printing mechanism technology, applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems of high labor consumption, unfavorable enterprise development, low efficiency, etc., and achieve high production efficiency and product quality control Good, improve the printing quality and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

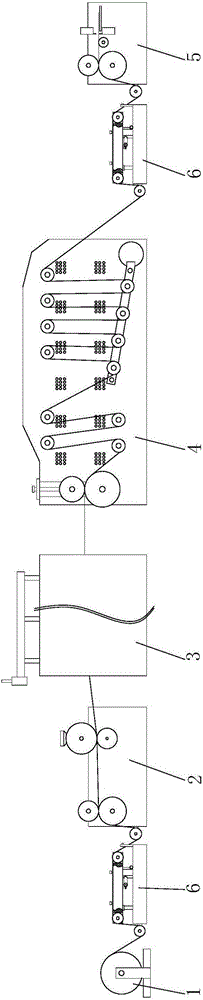

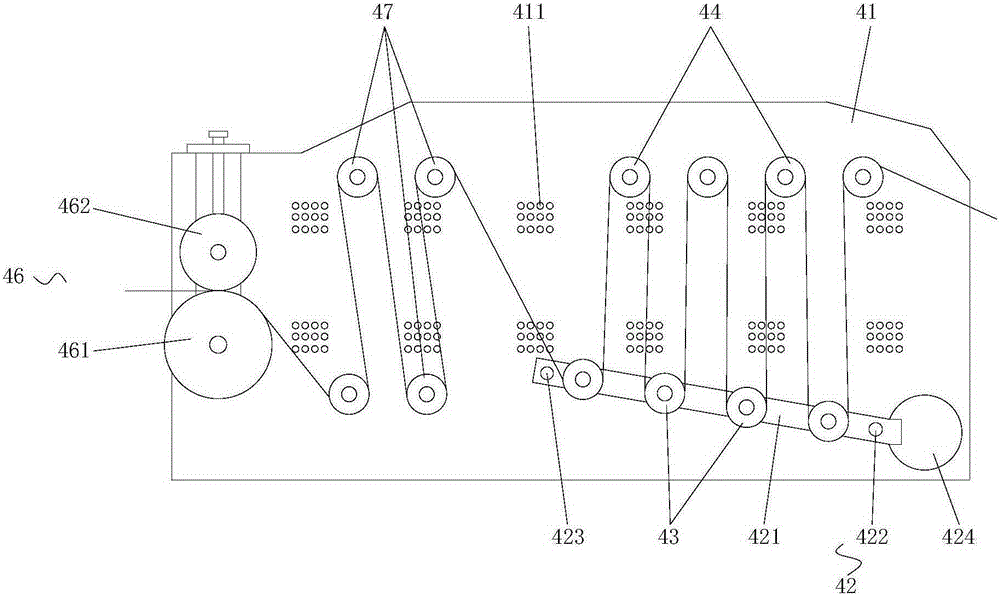

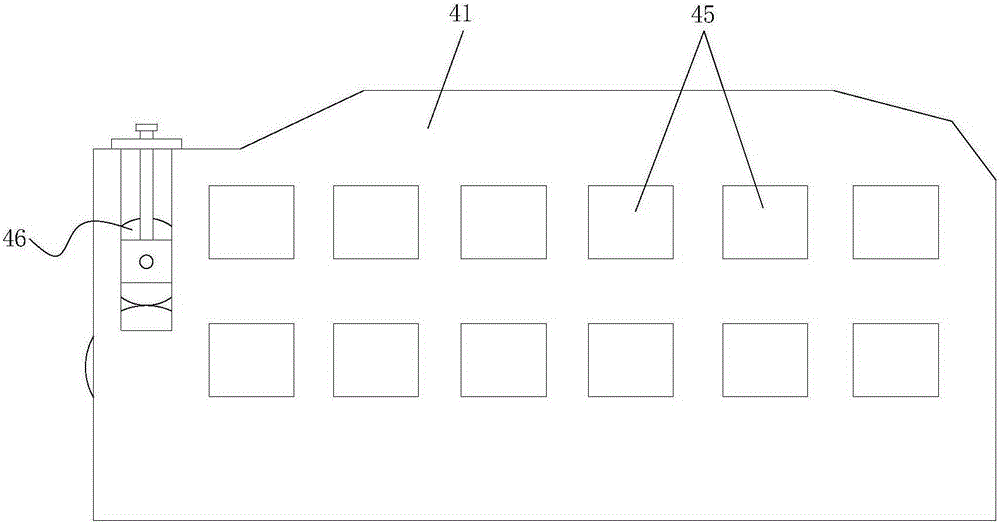

[0022] Figures 1 to 5 As shown in one of them, the present invention is an automatic control color card coating printing machine, which sequentially includes a curling mechanism 1, a coating printing mechanism 2, a drying box 3, and a cooling buffer mechanism 4 along the flow direction of the color cardboard base. and slitting mechanism 5; the side of the inflow end of coating printing mechanism 2 and slitting mechanism 5 is provided with a deviation correction mechanism 6; the color card coating printing machine also includes a PLC control system. PLC control system is used for control to realize automatic production, high production efficiency and good product quality control. Wherein, the coating printing mechanism 2 and the cutting mechanism 5 are existing products on the market, and belong to the prior art.

[0023] In the working process of the present invention, the color cardboard base is sent out by the curling mechanism 1, and the color mark layer is first printed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com