Auxiliary disassembly-assembly device for deep-sea airtight cabin

A sealed cabin and deep-sea technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve problems such as failure of centering between the end cover and the cabin, damage to the sealing ring, and uncoordinated assembly progress of multiple screws. Achieve the effect of saving manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

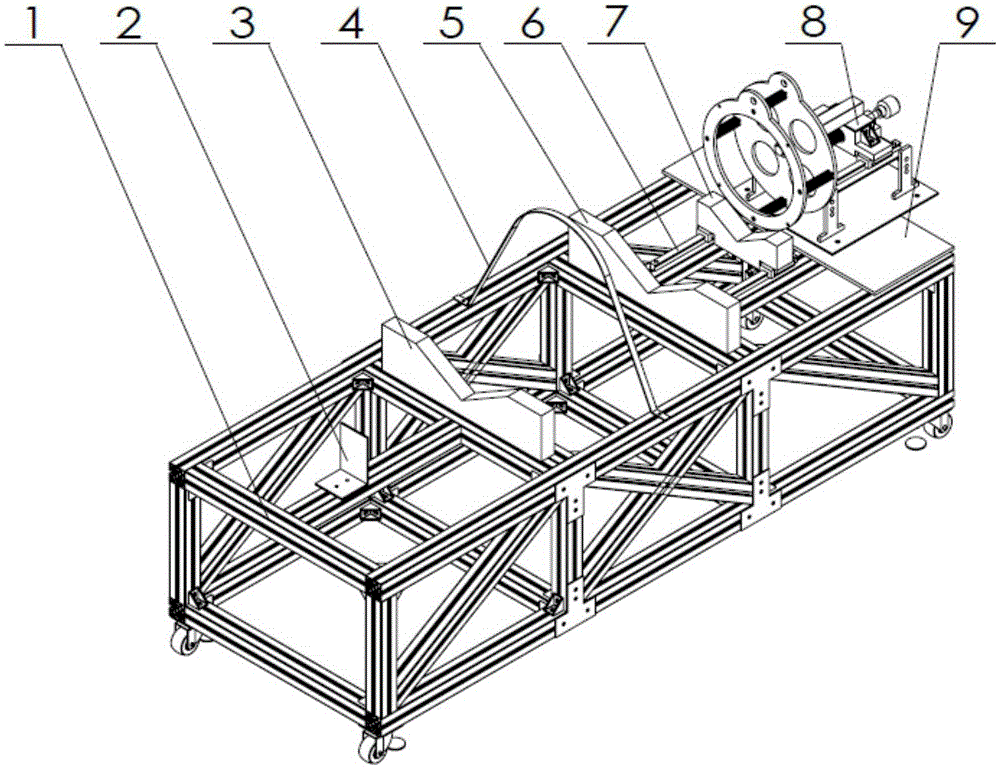

[0018] refer to figure 1 , the auxiliary dismounting device for the deep-sea airtight cabin, including a support seat 1, a motion positioning device 8, a fixing clip 4 for fixing the deep-sea airtight cabin, and a support base plate 9 sequentially fixed on the upper surface of the support seat 1, a pair of parallel first Linear guide rail 6, the first V-shaped plate 5, the second V-shaped plate 3, and the L-shaped block 2 for supporting the sealed cabin body;

[0019] The support base 1 is used to support the whole device, and 4 universal wheels and 4 feet can be installed on the bottom to facilitate the movement and fixing of the device.

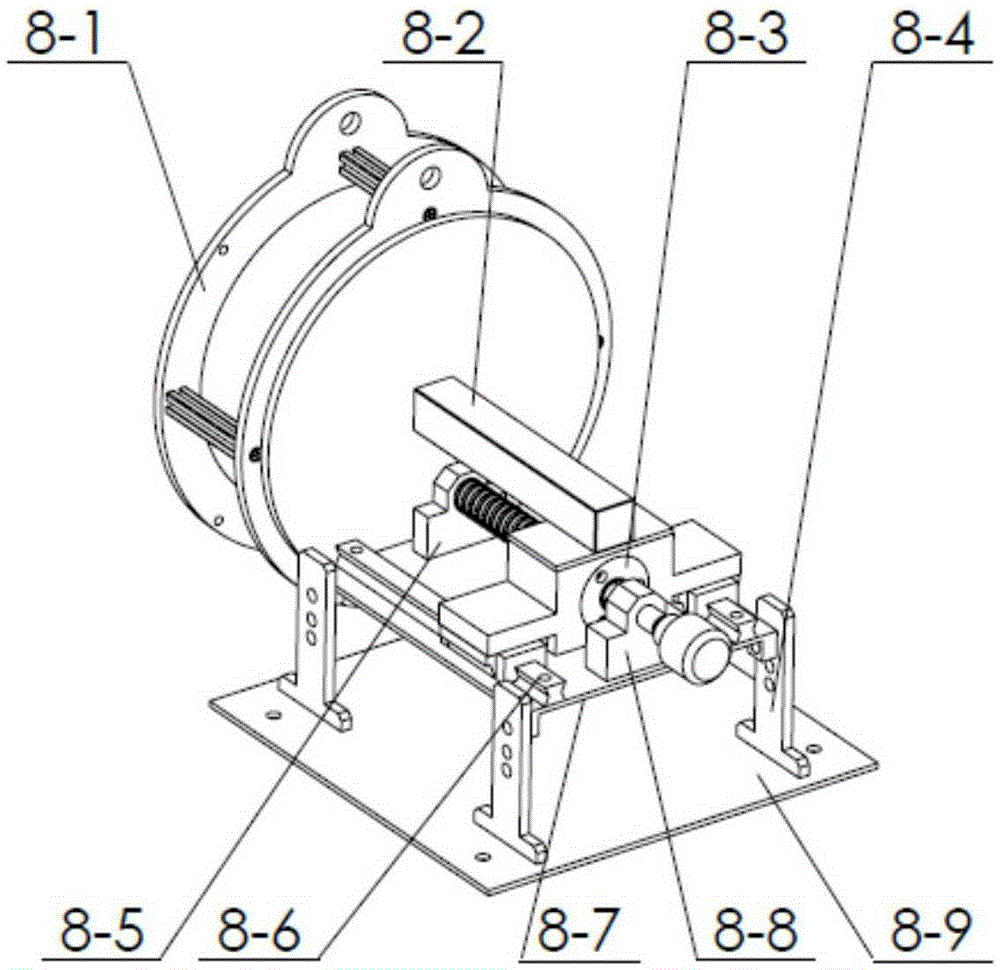

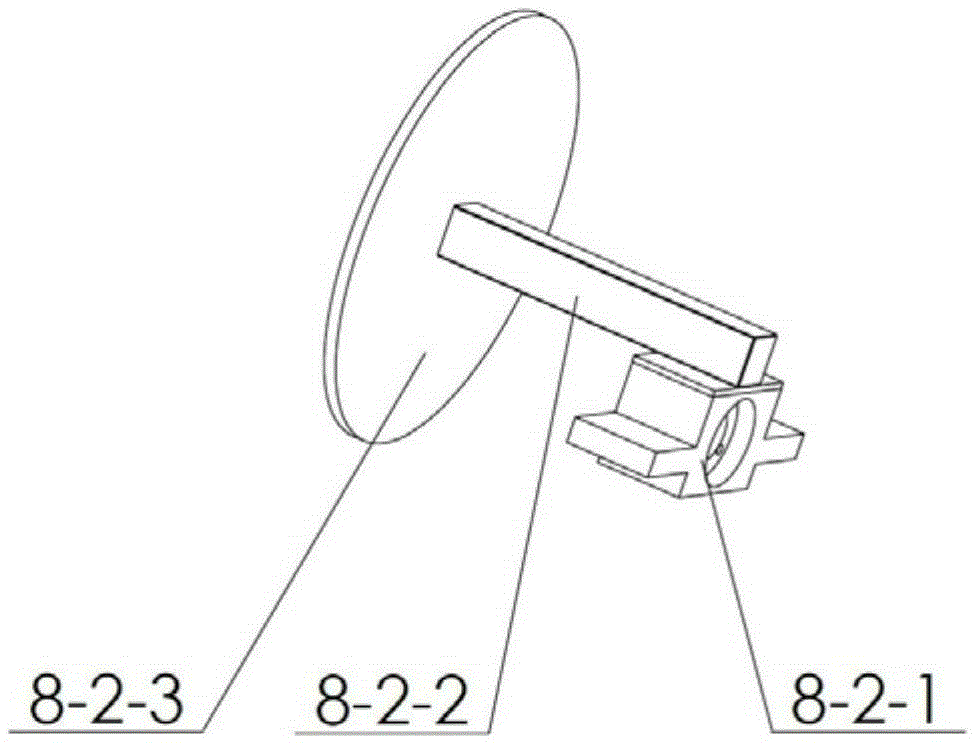

[0020] Such as figure 2 As shown, the motion positioning device 8 includes a base plate 8-9 fixed on the support base plate 9, four supports 8-4 fixed on the base plate 8-9, a support plate 8-7, a mobile platform 8-2 and a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com